Welding fixture for automobile part machining

A technology for welding jigs and auto parts, applied in the field of auto parts processing, can solve the problems of complicated welding jig process, large positioning error, welding error, etc., to ensure repeated use, avoid sideslip and offset, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

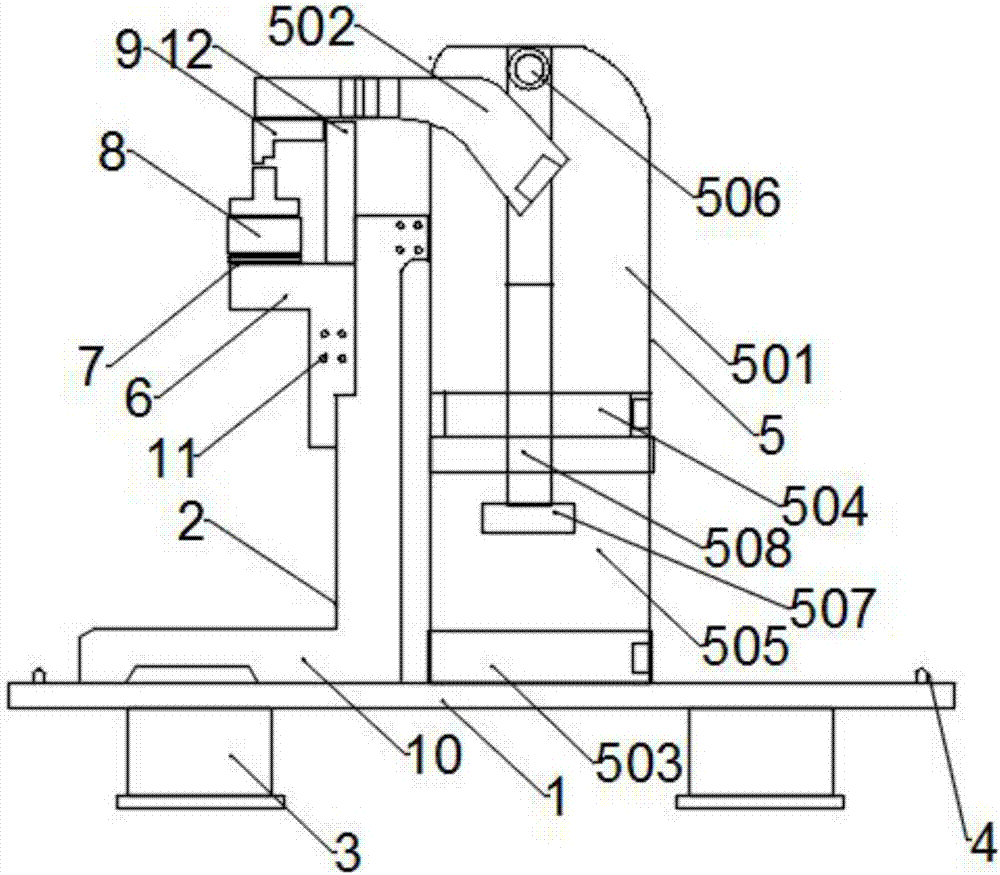

[0023] like figure 1 As shown, the present invention provides a welding fixture for the processing of automobile parts, including a fixture base plate 1, a clamp body 2 and a base 3, the fixture base plate 1 is in a horizontal state, is a regular rectangular plate, and adopts channel steel or square The upper surface of the fixture bottom plate 1 is marked with coordinate scale lines for the detection of the reference condition of the fixture. The four corners of the fixture bottom plate 1 are fixed with lifting lugs 4 to facilitate the movement and lifting of the welding fixture. The top of the base plate 1 is fixed with a clamp body 2 by screws, and a base 3 is welded below the clamp base plate 1. The clamp base plate 1 is a working platform that carries the weight of the clamp body 2 and the welding parts in the welding fixture.

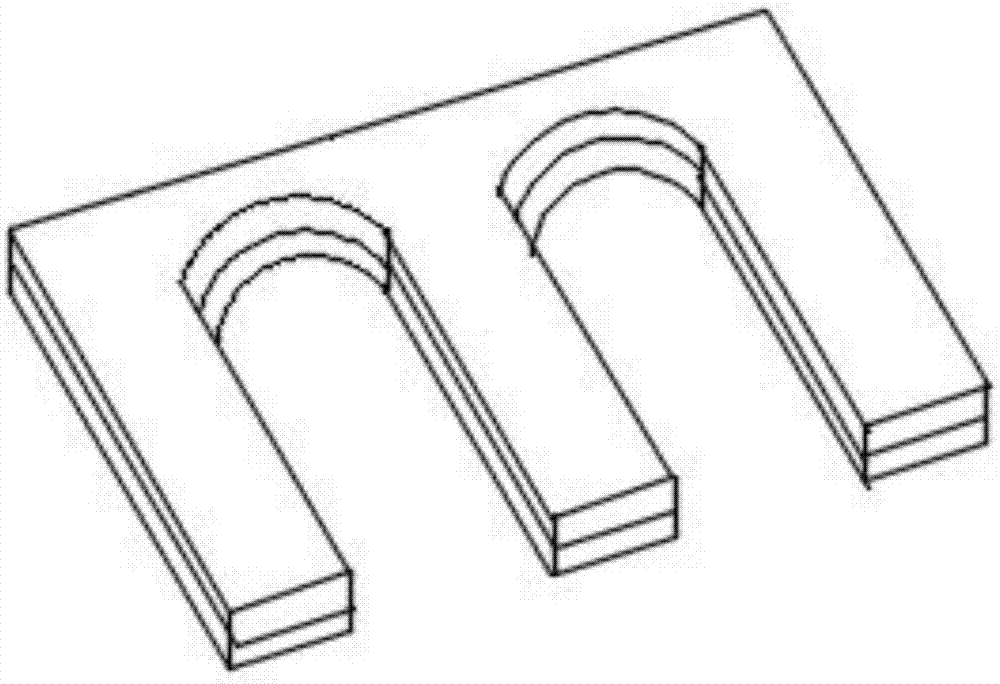

[0024] like figure 1 and figure 2 As shown, the clamp body 2 includes a pressing device 5, a transition block 6 and a support seat 10, the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com