Full-automatic tying and ring-sleeving device and operation method for same

A fully automatic, looping technology, applied in the fields of botanical equipment and methods, horticulture, plant cultivation, etc., can solve the problems of extrusion and deformation of the mouth of the material bag, non-standard manual sealing, and extrusion of the mouth of the material bag. Ease of operation, improved efficiency, and the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

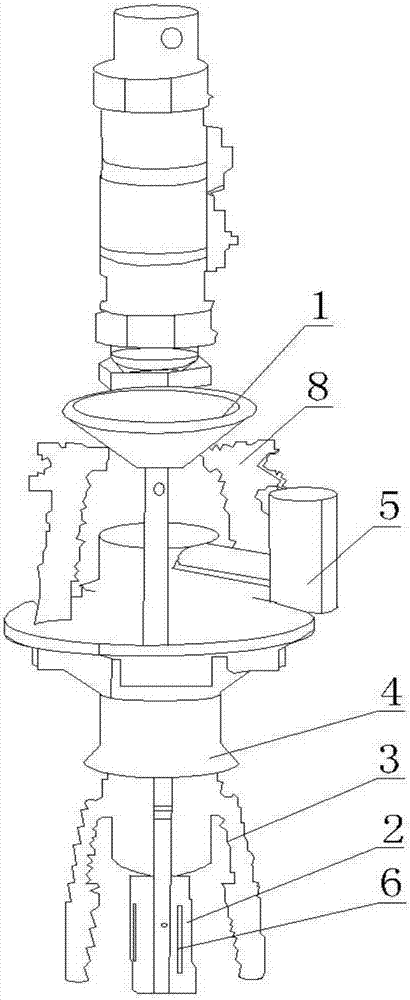

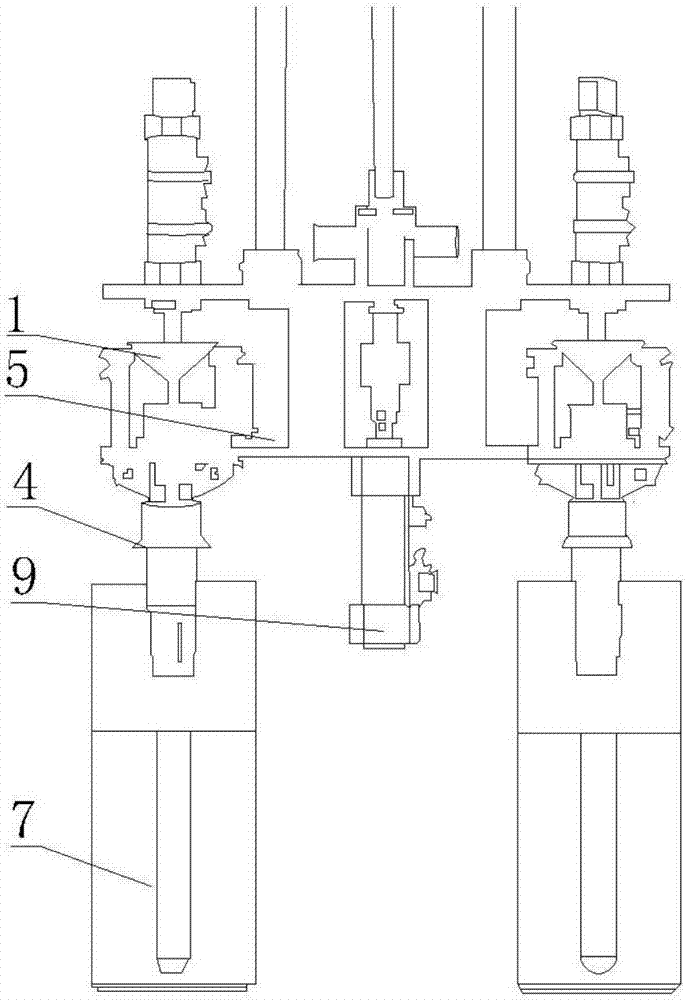

[0034] Such as figure 1 , figure 2 , image 3 As shown, a fully automatic beam mouth collar device includes a centering adsorption tube 2, a first jaw 3, a first cylinder, and a second cylinder 9, and the outer periphery of the upper end of the centering adsorption tube 2 is provided with a first jaw 3 And the first air cylinder, the first air cylinder brings the mouth of the material bag 7 into the gap opened by the first jaw 3; the upper end of the centering adsorption tube 2 and the position where the first jaw 3 is located is provided with a second clamp Claw 8, lower pressing block 1, second cylinder 9, lower pressing block 1 is connected with centering adsorption pipe 2, and second cylinder 9 drives lower pressing block 1 to move to control the closing of second jaw 8.

[0035] The full-automatic beam mouth collar device described in this embodiment is mainly aimed at technical problems such as large differences in the collar seal of the existing artificial beam bag c...

Embodiment 2

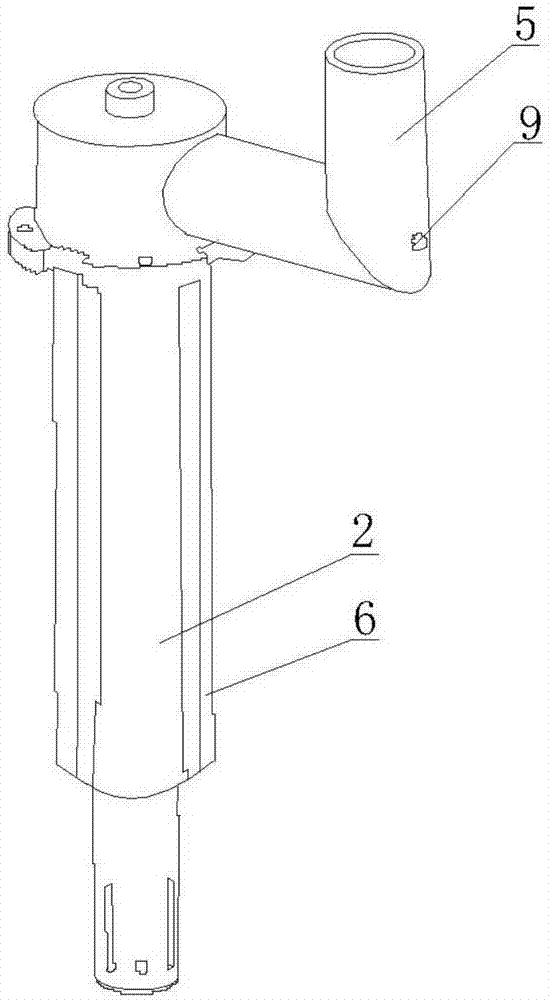

[0039] The difference between this embodiment and the above-mentioned embodiments is that the centering adsorption tube 2 is a hollow tube, and the lower end of the centering adsorption tube 2 is provided with a suction port 6, and the upper end of the centering adsorption tube 2 is also connected with a windshield 5 , the elbow of wind shield 5 is connected with blower fan. The air suction port 6 is a strip-shaped slit. The curved pipe of the wind cover 5 is provided with a blowing air port 10 , and the curved pipe of the wind cover 5 is connected with the blowing air pipe through the blowing gas port 10 .

[0040] In this embodiment, the air suction port 6 is provided on the outer surface of the centering adsorption pipe 2, which can effectively adsorb the mouth of the material bag and filter out material residues to avoid blocking the adsorption pipe.

[0041] In this embodiment, the inside of the centering adsorption pipe 2 communicates with the wind cover 5, and the fan ...

Embodiment 3

[0043]The difference between this embodiment and the above embodiment is that the number of the first clamping jaws 3 is two, and the two first clamping jaws 3 are symmetrically distributed with the center of the centering adsorption tube 2 as the central axis.

[0044] The number of the second jaws 8 is two, the two second jaws 8 are symmetrically distributed with the center of the centering adsorption tube 2 as the central axis, and the ends of the two second jaws 8 are all upward.

[0045] The jaw ends of the two second jaws 8 are provided with springs. The spring arranged on the second jaw 8 drives the second jaw 8 to open when the second cylinder 9 drives the lower pressing block 1 to retract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com