High-rise residential building cable laying control system and method

A cable laying and control system technology, applied in cable laying equipment and other directions, can solve problems such as low degree of automation, unbalanced cable tension, and easy scratching, etc., to achieve a high level of automation, easy operation, and ensure the effect of laying quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

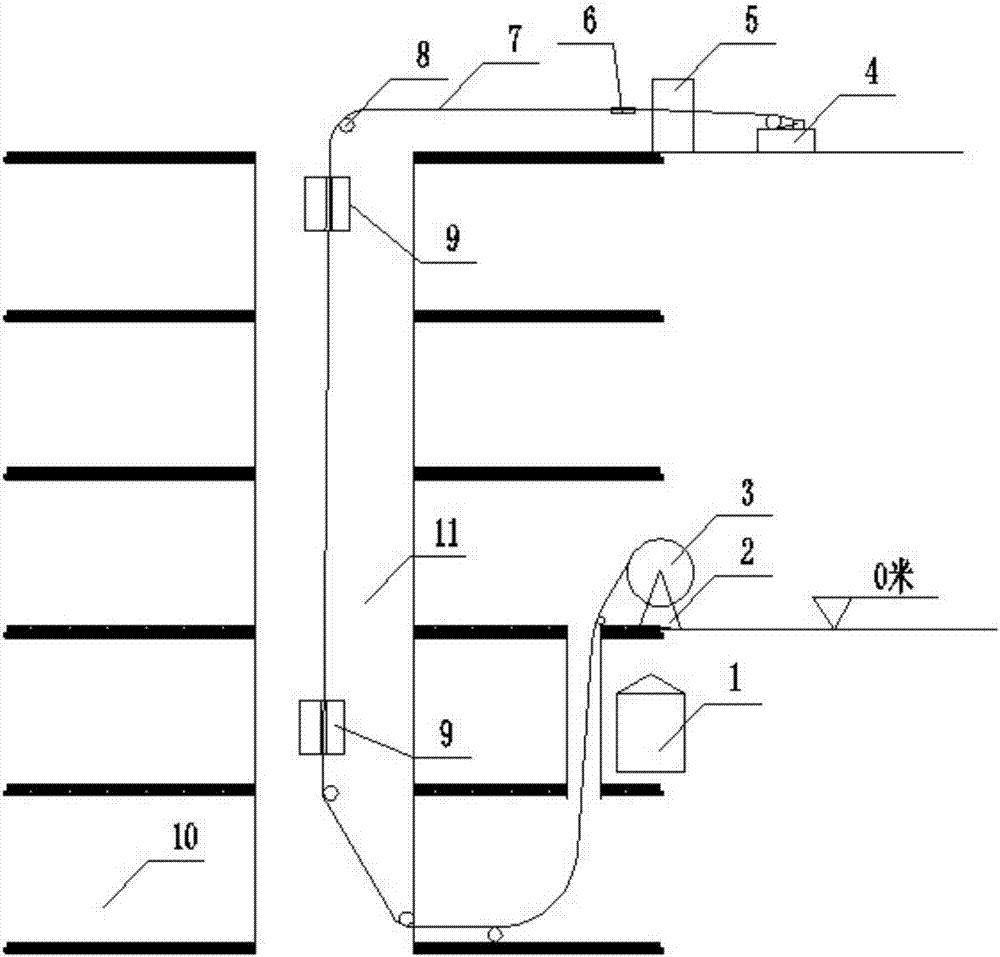

[0032] like figure 1 As shown, the present invention relates to a control system for laying cables in high-rise residential buildings, which is used for laying cables in high-rise residential buildings. The control system includes a control unit, a power unit and an auxiliary unit. The control unit is used to control the speed of the power unit. The power unit is used to run the cable 7 in the cable reel 3 from the ground through the strong electric well 11 from the basement 10 to the top floor of a high-rise residential building. When the cable 7 moves, it is used to provide power for the movement of the cable 7. The auxiliary unit is for the cable. 7 provides auxiliary power for the cable 7 during movement, and prevents the cable 7 from being in direct contact with the ground, so as to prevent the cable 7 from being scratched, so that the cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com