Substance leakage control method

A control method and material technology, applied in the direction of material size control, non-electric variable control, control/regulation system, etc., to achieve powerful functions, low power consumption, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

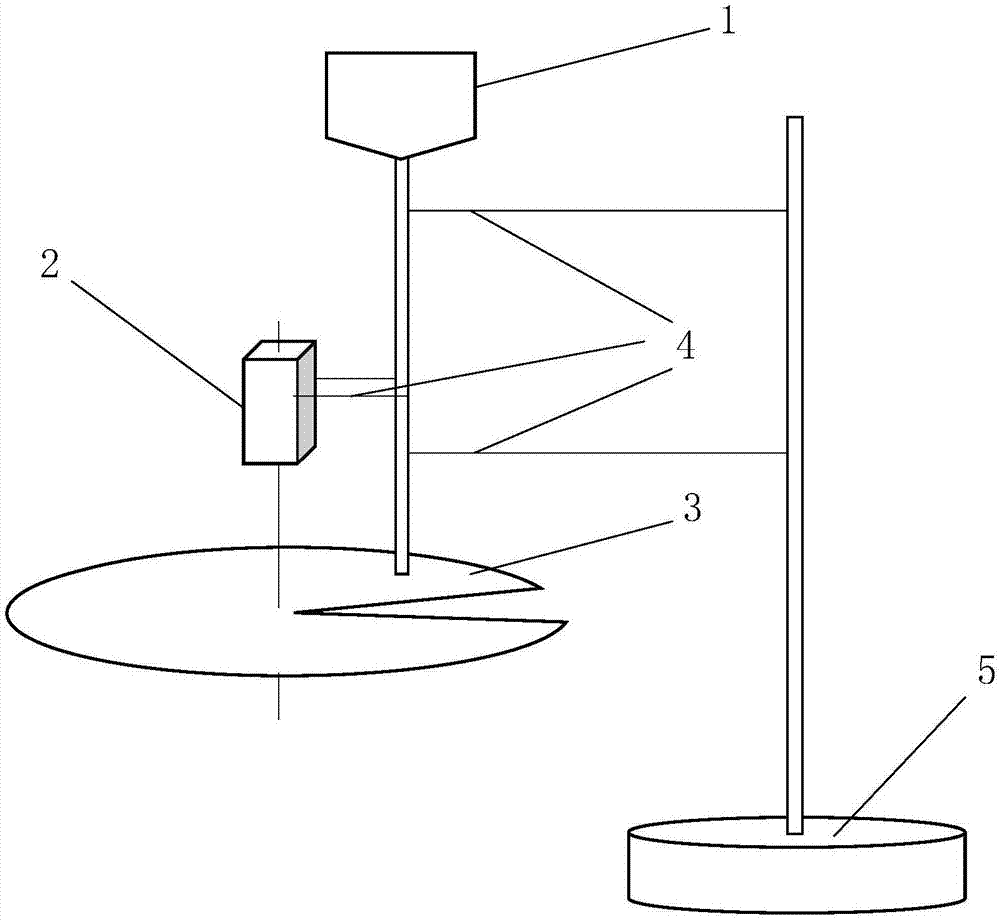

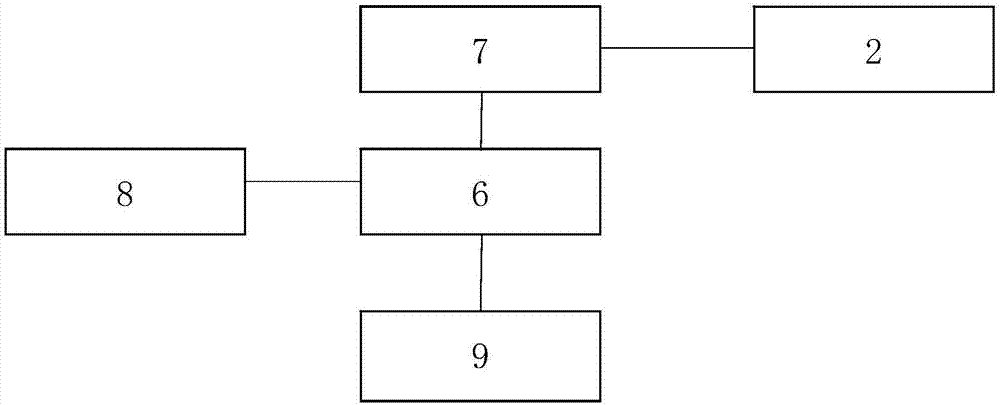

[0021] Embodiment 1. Substance leakage control method

[0022] The substance leakage control method in this example is a method of controlling the stepping motor through a single-chip microcomputer to accurately control the leakage amount of a certain substance: the substance leakage control method described is to use a single-chip computer software program to control the speed and rotation angle of the stepping motor. A method of precisely controlling the amount of leakage of a substance. The method for controlling the rotation speed and the rotation angle of the stepping motor is a method of controlling the rotation speed and the rotation angle of the opening disc through the stepping motor. As for the opening disc, the center of the disc is fixed on the drive shaft of the stepping motor, and there is a fan-shaped opening area formed by a set center angle on the disc. The fan-shaped opening angle described in this example is 15 degrees-180 degrees. The upper plane of the o...

Embodiment 2

[0023] Embodiment 2. Substance leakage control method

[0024] The difference between the substance leakage control method in this example and the substance leakage control method in Embodiment 1 is: according to the size of the substance, a long-necked funnel with a suitable lower port diameter can be selected, and a substance can be selected first, such as soybeans with a diameter of 8 mm. As an example, select a plastic long-necked funnel with a diameter of 1 cm and a length of 30 cm, select a disc made of plastic material with a fan-shaped gap, the radius of the disc is 10 cm, and the fan angle is temporarily taken as 60 degrees. The program sets an initial rotation speed of the stepping motor, and sets an alarm clock time, and sets the stepping motor to rotate only one circle after reaching the alarm clock time, and then staggers the opening part of the opening disc from the lower nozzle of the funnel, after downloading the program , turn on the power supply, after the st...

Embodiment 3

[0025] Embodiment 3. Substance leakage control method

[0026] The difference between the substance leakage control method in this example and the substance leakage control method in Embodiment 1 and Embodiment 2 is: if the stepper motor rotates one revolution, the leakage of soybeans is 10 grams, and the required soybeans are 30 grams, then the program can be modified , Appropriately reduce the rotation speed of the stepping motor so that 30 grams of soybeans are leaked out every time the stepping motor rotates. The rest of the material leakage control method of this example is the same as that described in Embodiment 1 and Embodiment 2, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com