Silage maize harvester material throwing cylinder control system and method

A technology of control system and silage machine, applied in general control system, control/regulation system, computer control, etc., can solve the problems of high cost, difficult layout of pipeline and valve body, complex structure, etc., achieve low cost, improve operation Efficiency and product market competitiveness, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

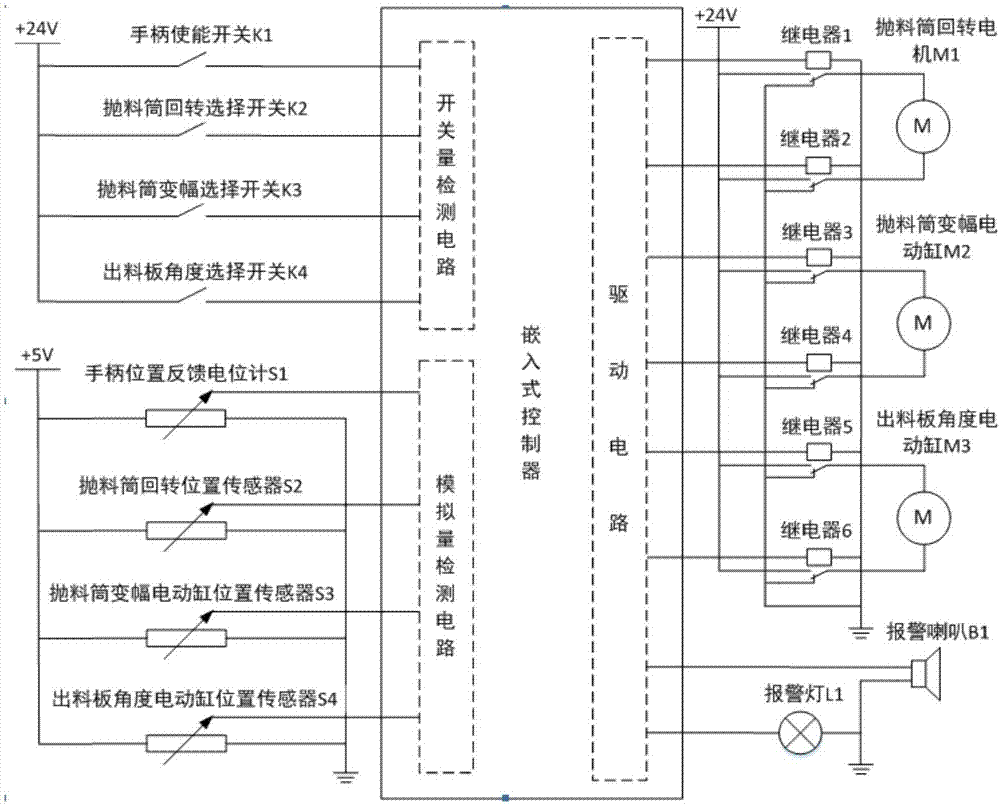

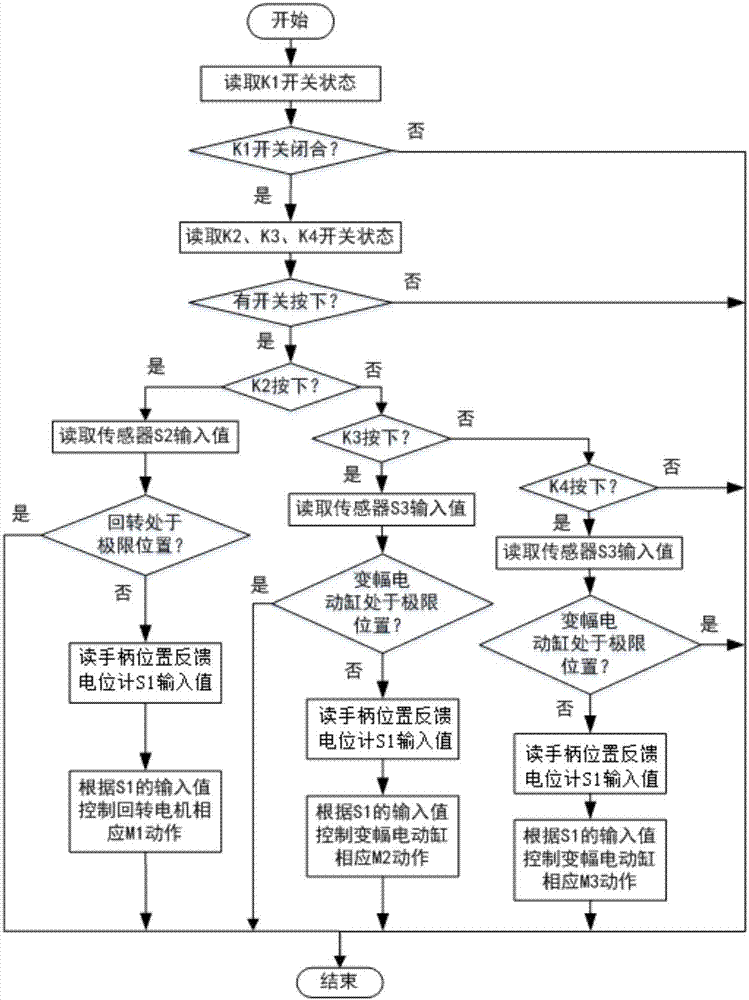

[0026] A silage machine throwing barrel control system of the present invention includes a control unit, an operation unit, a sensing unit and an execution unit, the control unit detects the states of the sensing unit and the operation unit, and controls the execution unit through a drive circuit, so that The execution unit controls the rotation angle of the throwing barrel, the amplitude of the throwing barrel and the angle of the discharge plate;

[0027] The sensing unit is connected to the control unit through a digital-to-analog conversion module, including a handle position feedback potentiometer S1, a rotary position sensor S2 of the throwing barrel, a position sensor S3 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com