Electric energy meter calibration device and usage method thereof

A technology for electric energy meters and meter calibration, which is applied in the direction of measuring devices, measuring electric variables, and power network operating system integration, etc. It can solve the problems of cumbersome operation and user inconvenience, and achieve the effect of convenient data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

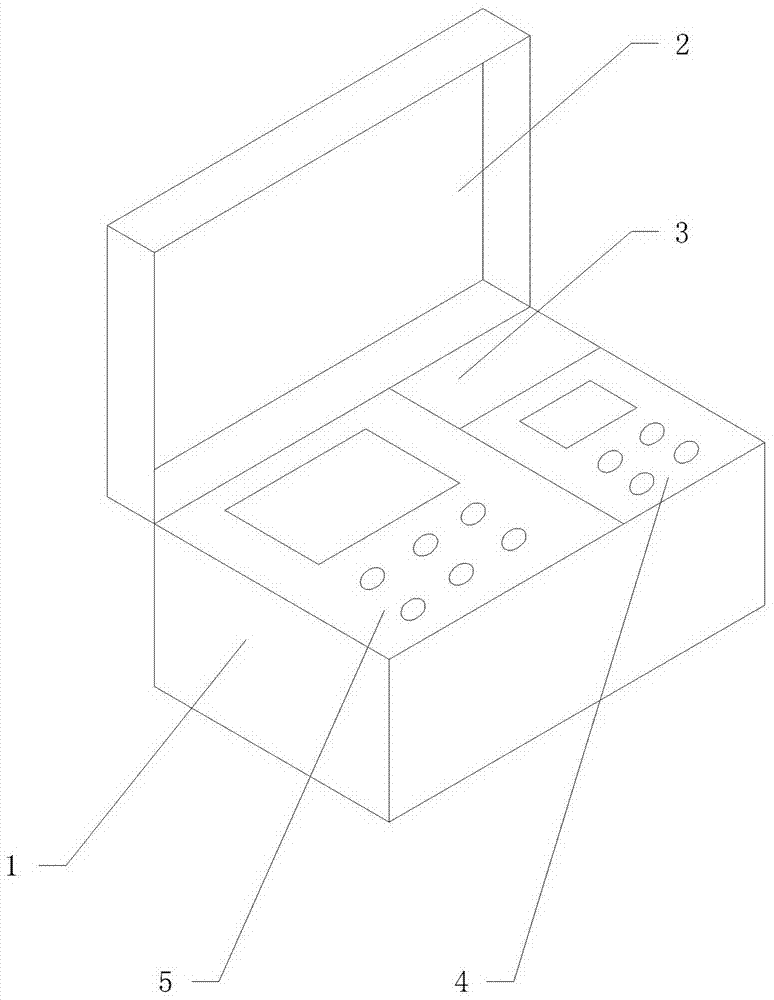

[0036] as attached Figures 1 to 4 As shown, the electric energy meter calibration device includes a box body 1 and a box cover 2, and the box body 1 is provided with an electric energy meter on-site calibrator 5, a spare electric energy meter 4 and a wire slot 3. The electric energy meter on-site calibrator 5 is connected with a wireless communication device. The box body 1 is provided with a handle.

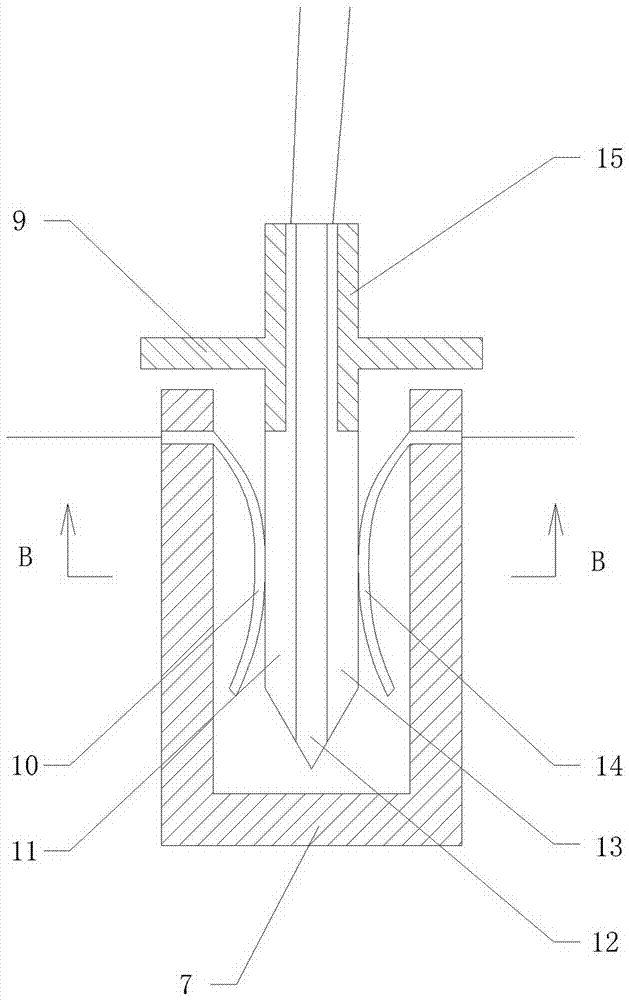

[0037] A plug 15 is arranged between the terminal 5 of the electric energy meter field calibrator and the terminal 4 of the standby electric energy meter, each terminal of the electric energy meter field calibrator 5 corresponds to a plug 15, and each terminal of the standby electric energy meter 4 corresponds to a plug 15. In this embodiment, the electric energy meter 6 to be calibrated has two terminals as an example, and the electric energy meter field calibrator 5 and the standby electric energy meter 4 respectively have two corresponding terminals.

[0038] The plug 15 ...

Embodiment 2

[0046] The method for using the energy meter calibration device includes the following steps:

[0047] A1, install the socket 7, connect the first elastic contact piece 10 with the user wire, the second elastic contact piece 14 is connected with the terminal of the watt-hour meter 6 to be calibrated, and each terminal of the watt-hour meter 6 to be calibrated corresponds to a socket 7.

[0048] The socket 7 should be installed together when the watt-hour meter 6 to be checked is installed.

[0049] A2. Check and reset the standby electric energy meter 4.

[0050] B. Close the switch 8, insert the plug 15 into the socket 7, the electric energy meter contact piece 11 corresponds to the first elastic contact piece 10, and the calibrator contact piece 13 corresponds to the second elastic contact piece 14.

[0051] When inserting the first plug 15, the user wire, the first elastic contact piece 10, the electric energy meter contact piece 11, the switch 8, the calibrator contact pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com