Polyester filament single filament cake fixed weight batch weighing device and weighing method thereof

A polyester filament and weighing device technology, which is applied in the field of polyester spinning production, can solve problems such as low production efficiency, deviation in fixed weight, and impact on product quality, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiment:

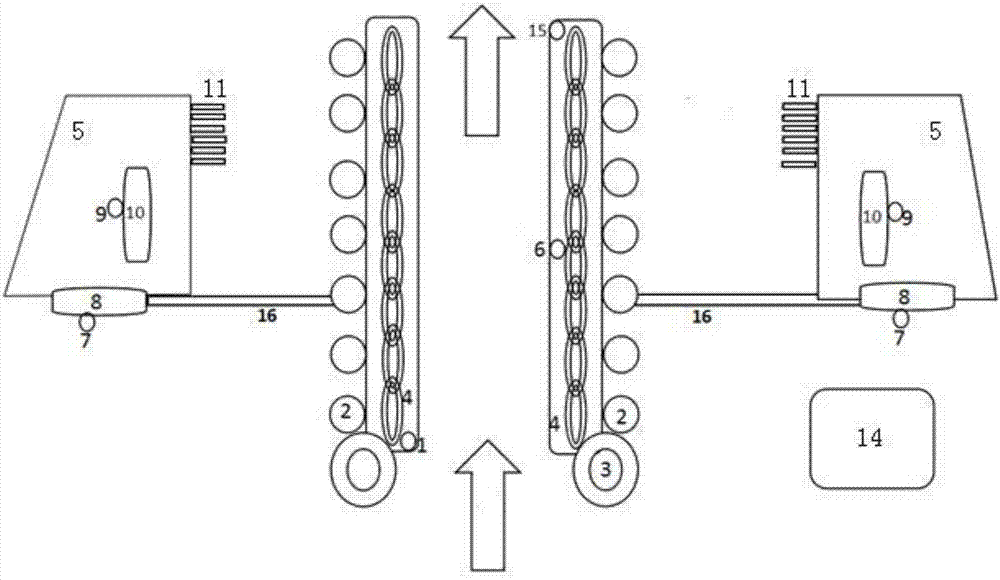

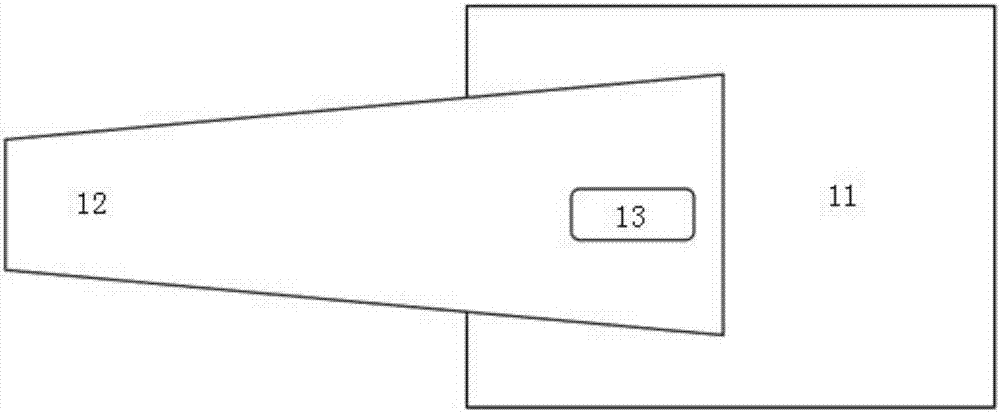

[0024] Such as figure 1 and 2 Described, a kind of polyester filament single silk cake fixed weight batch weighing device, comprises the chain conveyer belt 4 that is used to convey silk car, and there are two chain conveyer belts 4, and two chain conveyer belts 4 are arranged in parallel, and the chain conveyer belt Driven by the conveying motor 3, the input end and the output end of the chain conveyor belt are respectively provided with an inlet sensor 1 and an outlet induction switch 15, and the outer side of the chain conveyor belt 4 is respectively provided with a support wire support 5, a support wire support guide rail 16 and a driving support. The horizontal moving cylinder 8 that the wire support slides horizontally on the guide rail of the support wire support, the lifting cylinder 10 that drives the support wire support to move up and down on the support wire sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com