Chemical plant safety early warning method

A safety warning, chemical plant technology, applied in measurement devices, instruments, fire rescue and other directions, can solve the problems of inability to detect harmful gases and flammable gases, and inability to automatically take countermeasures, to avoid fire spread, simplify the difficulty, Easy-to-see effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

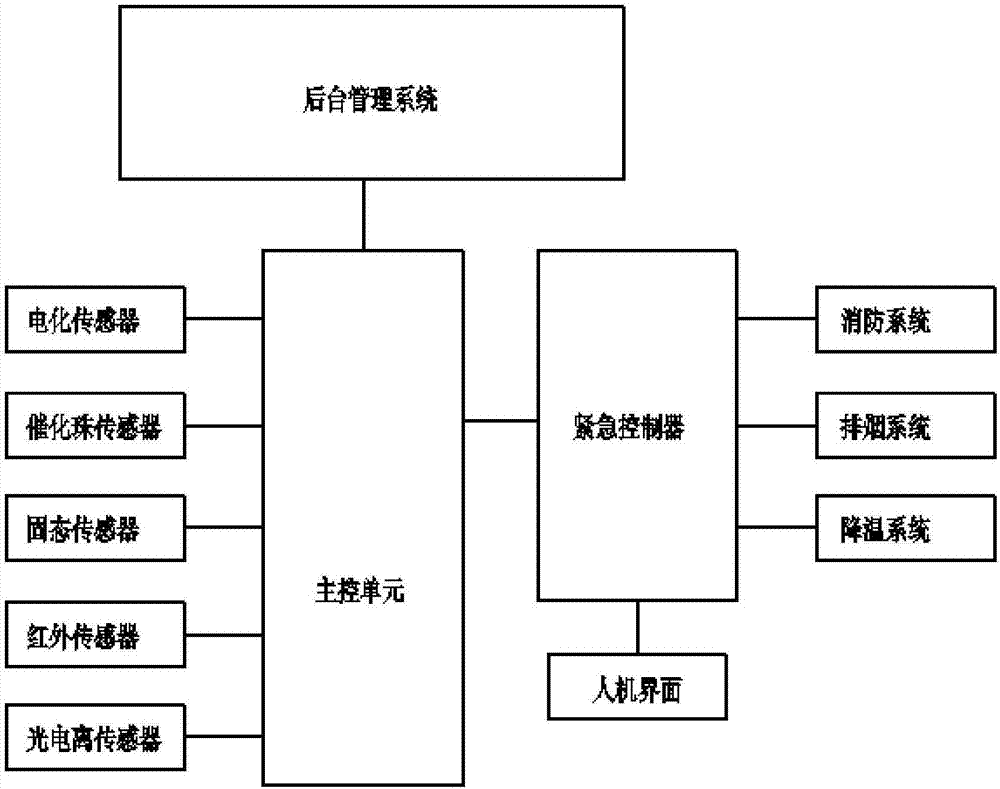

[0022] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the present invention provides a chemical plant safety early warning method, using electrochemical sensors to detect harmful gases in the air, using catalytic bead sensors to detect the concentration of combustible gases in the environment, using solid-state sensors to detect the concentration of toxic gas carbon monoxide in the air, using infrared The sensor detects the temperature; the aforementioned detection result is compared with a threshold, and emergency processing is performed when the threshold is exceeded.

[0024] The tenth realization of the present invention includes a main control unit, a background management system, an emergency controller, a fire-fighting system, a smoke exhaust system, a cooling system, an electrochemical sensor, a catalytic bead sensor, a solid-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com