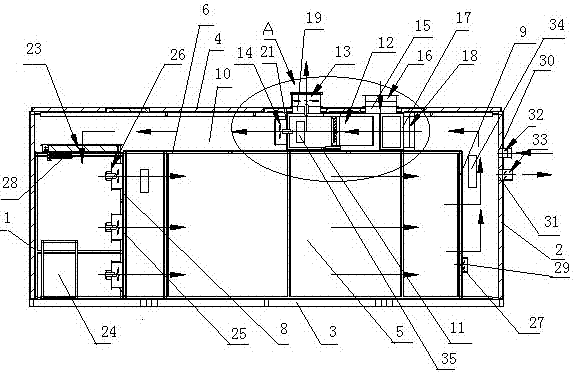

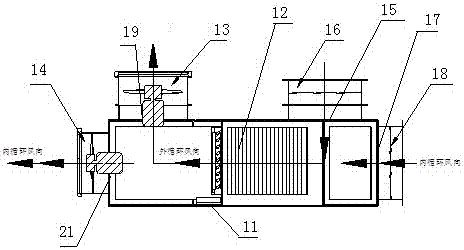

Air-source heat pump drying room

An air energy heat pump, drying room technology, applied in drying, dryer, drying gas layout and other directions, can solve the problems of poor reliability, large cost and volume, and reduced volume, and achieves a simple structure and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] First, set the drying temperature to 65°C and the humidity to 10%. Put the material into the drying room, turn on the system switch, and make the condenser, evaporator, circulating fan, and soaking fan work. When the humidity passing through the humidity sensor is 85%, 80% higher than the set value of the humidity sensor, the humidity is obviously too high, the humidity sensor transmits the humidity signal to the controller, and the controller controls the fresh air valve to open the dehumidification fan, open for rapid dehumidification, when the humidity is lower than the temperature When the set value of the sensor is 80%, the controller will close the humidity exhaust fan and the fresh air valve, and then carry out the internal drying and dehumidification process. After the temperature sensor in the drying room senses that the temperature is lower than the set temperature The external circulation is used for heating. At this time, the evaporator fan and the first elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com