Large coupling

A technology of large couplings and inner shafts, applied in the direction of couplings, sliding couplings, mechanical equipment, etc., can solve the problems of poor cushioning and vibration absorption performance, difficult installation and centering, and short service life, so as to reduce Vibration, speed stability, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] When implementing it:

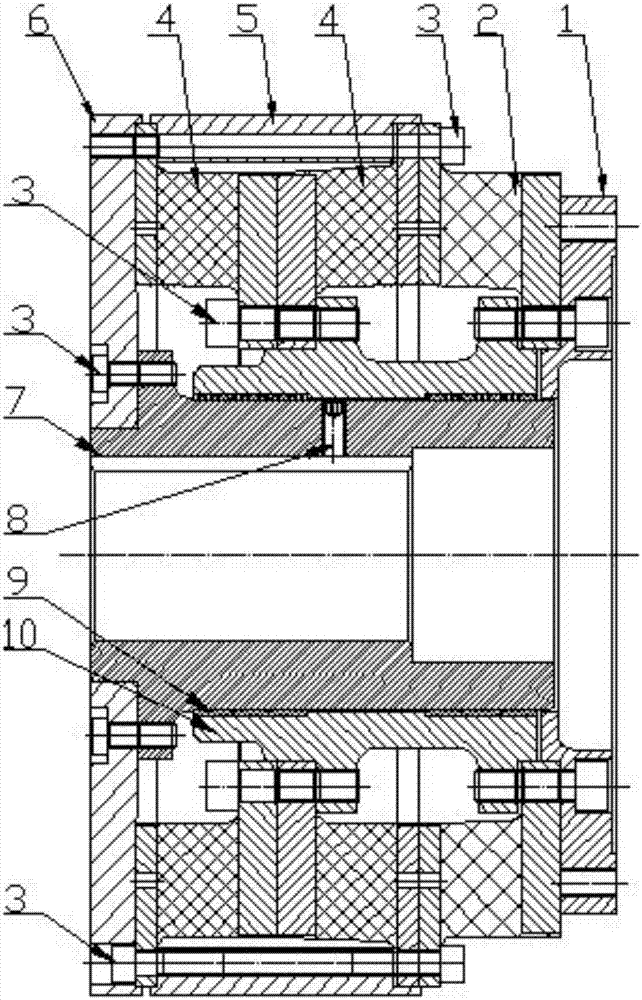

[0017] Such as figure 1 As shown, a large shaft coupling includes an inner shaft 7, an inner shaft sleeve 10 is arranged outside the inner shaft 7, a front end 4 of the body is arranged outside the outer shaft sleeve, and a front cover 2 and a rear body are respectively arranged on both sides of the front end 4 of the body. Cover 6, the front end cover 1 is arranged on the outside of the front cover 2 of the body, the front end 4 of the body, the front cover 2 of the body and the rear cover 6 are fixed with a housing 5 through the fixing part 3; the front end 4 of the body and the front cover of the body The other ends of 2 are all fixedly arranged on the inner shaft sleeve 10 through the fixing piece 3 , and the other end of the rear cover 6 is fixedly arranged on the inner shaft 7 through the fixing piece 3 . By fixing the front end 4 of the main body on the inner shaft sleeve 10 through the fixing piece 3, the function of shock absorption can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com