Multi-point support frame structure for integrated narrow-pipe wind-collecting power-generation system

A power generation system and multi-point support technology, which is applied in wind power generation, wind engine control, wind engine, etc., can solve problems such as equipment damage, large and complex structure, and poor support strength, and achieve simple structure, improved safety, and easy use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below.

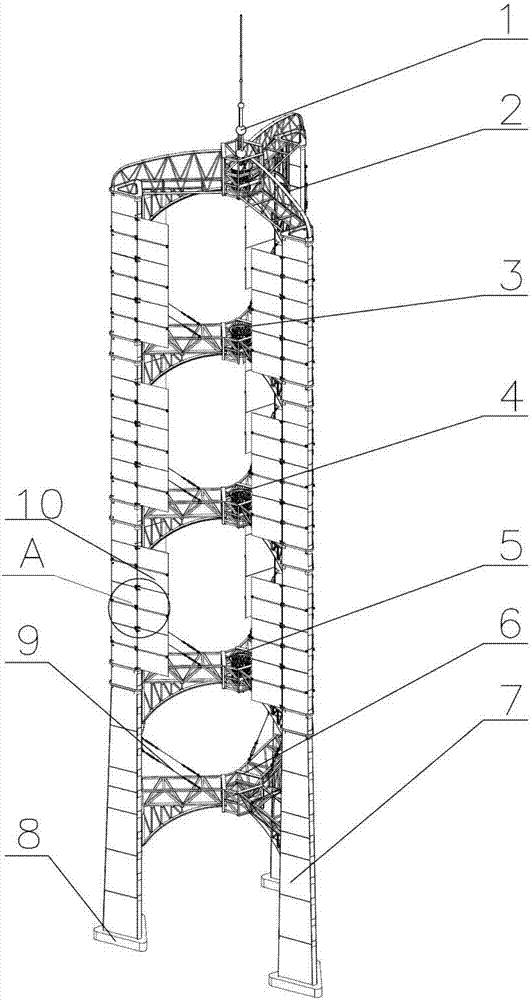

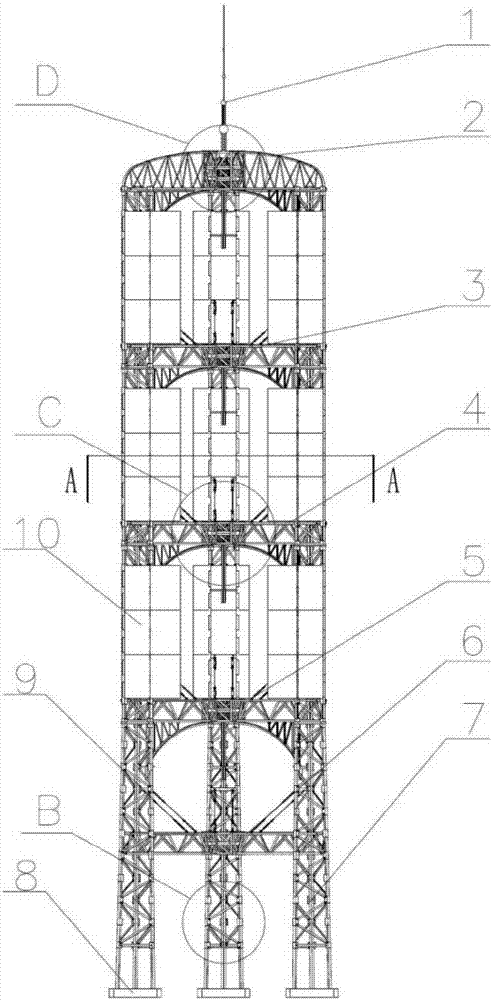

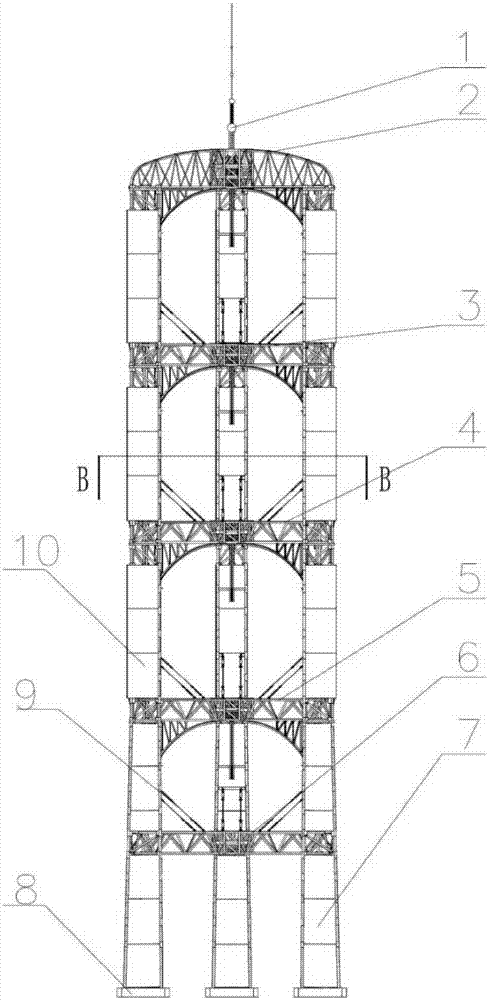

[0026] Such as figure 1 , figure 2 and image 3 As shown, a multi-point support frame structure for an integrated narrow-tube wind-gathering power generation system includes a plurality of support tower legs 7, and a plurality of The support assembly for installing the tube includes a first support platform 3 , a second support platform 4 and a third support platform 5 ; the movable louvers 1903 are made of perforated plates or breathable fabrics with through holes on the surface. The tops of each supporting tower leg 7 are connected with the outwardly extending end of the tower top 2, as Figure 6 As shown, a tower top support platform 201 is also provided on the tower top 2 , and the tower top support platform 201 is arranged at the center of the tower top 2 . Such as Figure 5 As shown, a lightning rod 1 is also provided on the support platform 201 at the top of the tower. The position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com