Turbo supercharged engine air inlet system noise reduction structure

An air intake system, turbocharging technology, applied in the direction of combined air filter and muffler, can solve problems such as reducing supercharging pressure, increasing NVH problems, pressure changes, etc., to achieve the effect of improving car comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

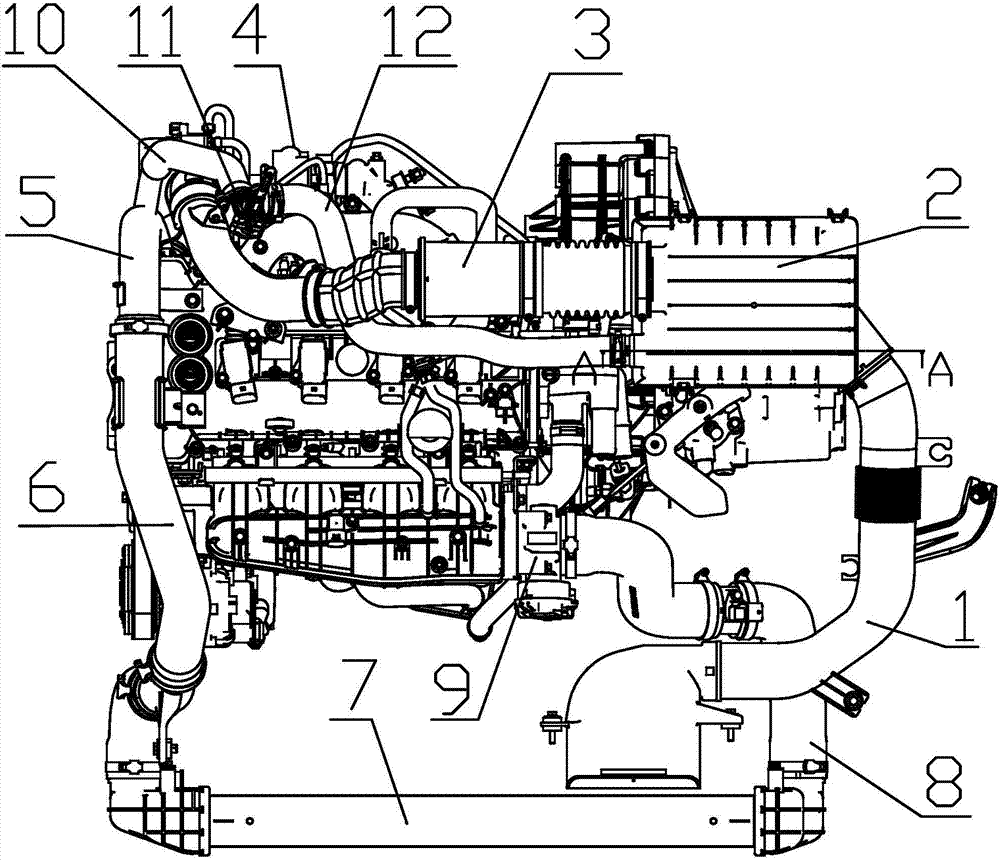

[0024] refer to Figure 5 In the circuit diagram of the supercharged engine intake system shown, the air enters the air filter assembly 2 through the air filter intake pipe 1, the air filter outlet pipe 3 of the air filter assembly 2 communicates with the turbocharger 4, and the supercharged air outlet pipe 5 It communicates with the intermediate condensate air intake pipe 6, and the pressurized gas enters the intercooler 7 through the intermediate condensate air intake pipe 6, and then reaches the engine throttle 9 through the intercooler outlet pipe 8, thereby increasing the gas volume, but when the driver When the intake pressure is too high when the pedal is released, it is necessary to relieve the pressure of the gas in the pressurized air outlet pipe 5, then the pressurized air outlet pipe 5 is also connected with the electronic pressure relief valve 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com