Device and method used for seaming tubular fabric

A technology for tubular fabrics and sewing devices, which is applied to the looping machine, knitting, and sewing equipment used to connect knitted fabrics. It can solve the problems of increased labor costs, tubular fabric jamming, and unfavorable large-scale promotion, and achieves reduced complexity and Failure rate, effect of reducing air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

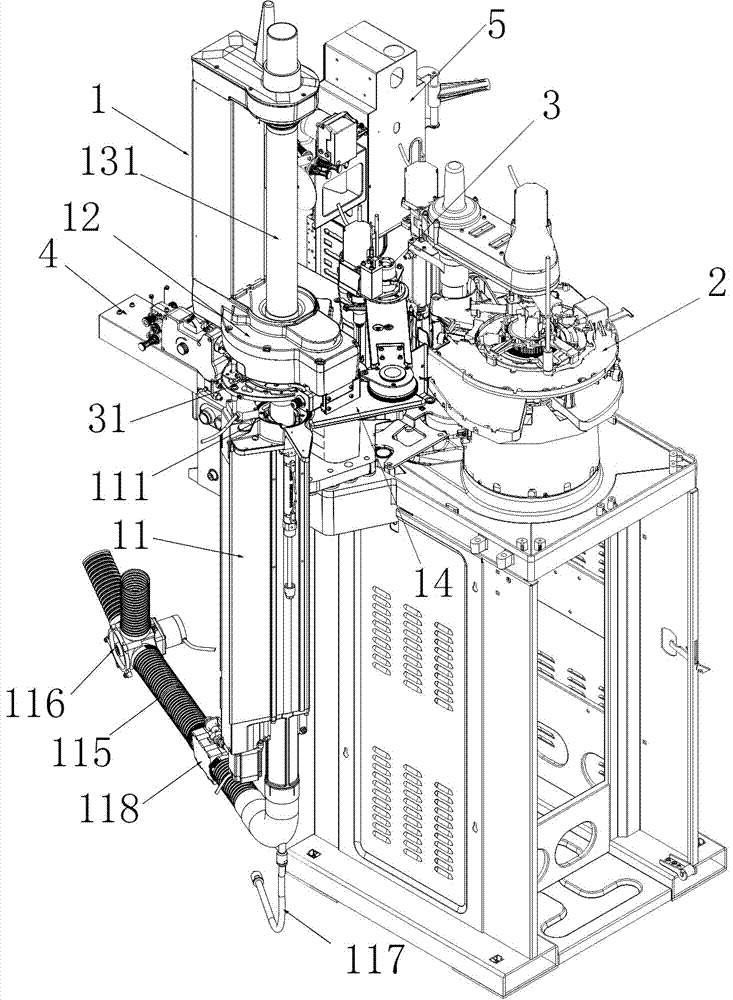

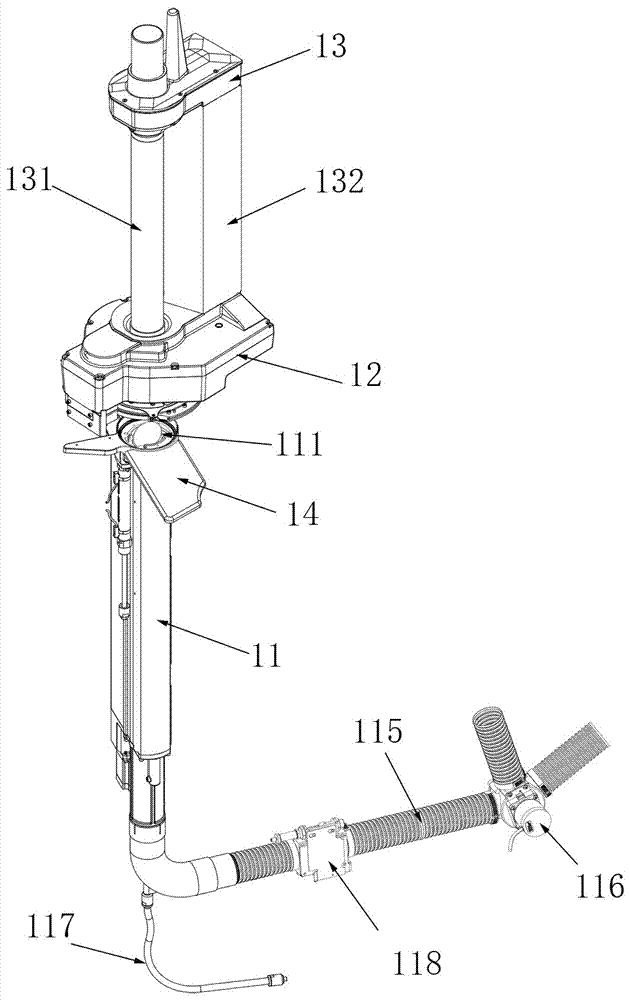

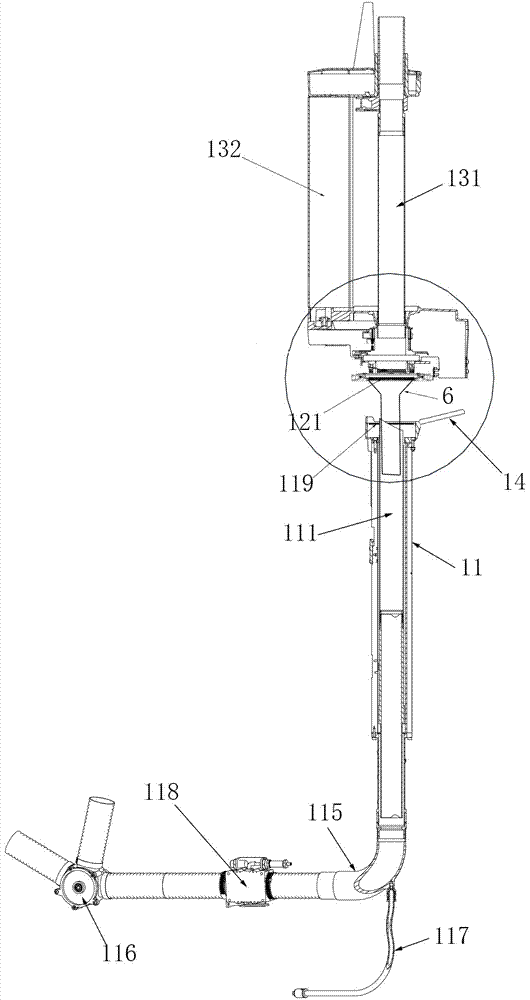

[0044] See attached picture. The present embodiment comprises overturning device 1, circular knitting machine 2, transfer device 3, sewing device 4 and frame 5; Described frame 5 is placed on the side of circular knitting machine 2, and overturning device 1 is installed on the frame 5 , there is a platform 14 on the side of the turning device 1, the surface of the platform is a smooth material, one end of the platform 14 is fixed on the turning device 1, and the other end of the platform is close to the circular knitting machine 2, which can be placed on the circular knitting machine or not. It is towards the circular knitting machine, and the platform 14 is located below the moving track of the transfer plate 31 to facilitate the transfer of the tubular fabric.

[0045] Turning device 1 can be divided into suction component 11, clamping component 12 and delivery component 13; Driven by the transfer arm, it moves back and forth; the transfer disc is a ring structure, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com