Electrolyte for preparing calcium through fused salt electrolysis of calcium chloride, and electrolysis method using electrolyte

The technology of a calcium chloride molten salt and an electrolysis method is applied in the field of electrolytes for calcium production by electrolysis of calcium chloride molten salt, which can solve the problems of metal calcium floating, high labor and cost, large consumption of raw materials, etc. The effect of convenient operation and management, and efficient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

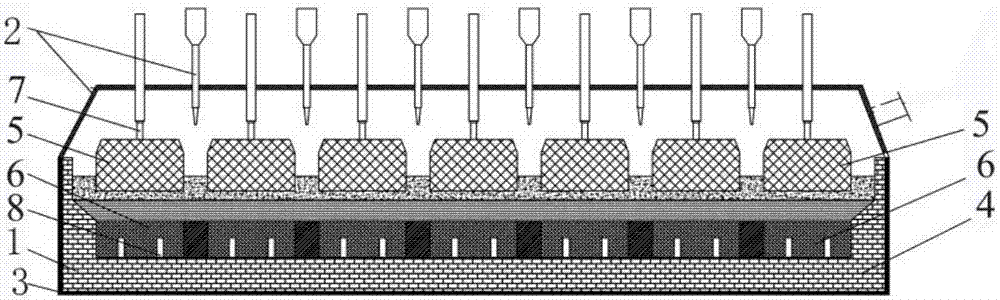

Image

Examples

Embodiment 1

[0026] The mole percent composition of electrolyte in the present embodiment is: 12% CaCl 2 , 15% LiCl, 15% KF, 7% CaF 2 , 51% KCl.

[0027] The performance of the electrolyte described in this embodiment is measured, and the result is: the density of the electrolyte in this embodiment is 1.48g / cm 3 , the primary crystal temperature is 600°C, and the conductivity is 3.25S.cm -1 .

Embodiment 2

[0029] The mole percentage composition of electrolyte in the present embodiment is: 10% CaCl 2 , 10% LiCl, 20% KF, 6% CaF 2 , 54% KCl.

[0030] The performance of the electrolyte described in this embodiment is measured, and the result is: the density of the electrolyte in this embodiment is 1.43g / cm 3 , the primary crystal temperature is 594°C, and the conductivity is 3.43S.cm -1 .

Embodiment 3

[0032] The mole percent composition of electrolyte in the present embodiment is: 15% CaCl 2 , 20% LiCl, 12% KF, 8% CaF 2 , 45% KCl.

[0033] The performance of the electrolyte described in the present embodiment is measured, and the result is: the density of the electrolyte in the present embodiment is 1.54g / cm 3 , the primary crystal temperature is 608°C, and the conductivity is 3.12S.cm -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com