Ca-Zn composite stabilizer production system and production technology thereof

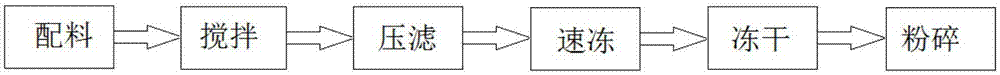

A calcium-zinc composite and production system technology, which is applied in the coating and other directions, can solve the problems of poor stability of calcium-zinc heat stabilizers and long production process cycle, so as to reduce dehydration energy consumption, increase the steps of pressure filtration, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

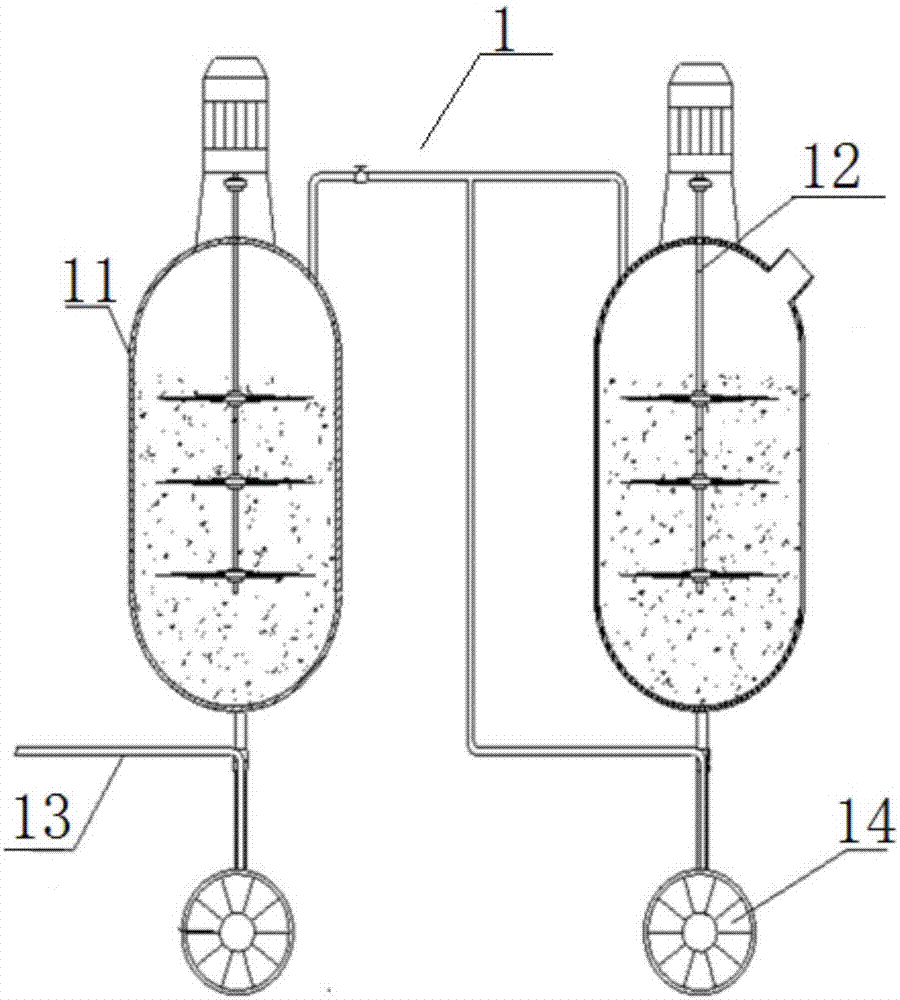

[0043] The calcium-zinc composite stabilizer production system of the present embodiment comprises a stirring device 1, a drying device 3 and a pulverizing device arranged and connected sequentially according to the technological process; wherein: as figure 2 As shown, the stirring device 1 includes a reactor 11, a stirring rod 12, a discharge pipe 13 and a water pump 14, and the stirring rod 12 is inserted directly into the middle and lower part of the reactor 11, and the bottom of the discharge pipe 13 and the reactor 11 In communication, the water pump 14 communicates with the top of the reactor 11 through a water pipe. The drying device 3 is a dryer.

[0044] The calcium-zinc composite stabilizer of the present embodiment, the component of its batching comprises the calcium salt of the composite carboxylic acid of 30 parts by weight and the zinc salt for use in the present embodiment of calcium stearate and zinc stearate, each 8 parts by weight of Paraffin and stearic ac...

Embodiment 2

[0052] The calcium-zinc composite stabilizer production system of the present embodiment, basic structure is the same as embodiment 1.

[0053] The calcium-zinc composite stabilizer of the present embodiment, basic batching is the same as embodiment 1, difference and improvement point are: the component of its batching comprises calcium stearate and zinc stearate each 40 parts by weight, each 12 parts by weight of Paraffin and stearic acid, and 8 parts by weight each of beta-diketone and octanoylbenzoylmethane.

[0054] In the processing technology of the calcium-zinc composite stabilizer of this embodiment, the step of press filtration is added after step 2 is stirred, which can reduce the burden of subsequent dehydration and drying, improve the efficiency of the processing technology, and reduce dehydration energy consumption; After the water is collected, in the next batch of production, the calcium salt and zinc salt solutions of complex carboxylic acids are used in step t...

Embodiment 3

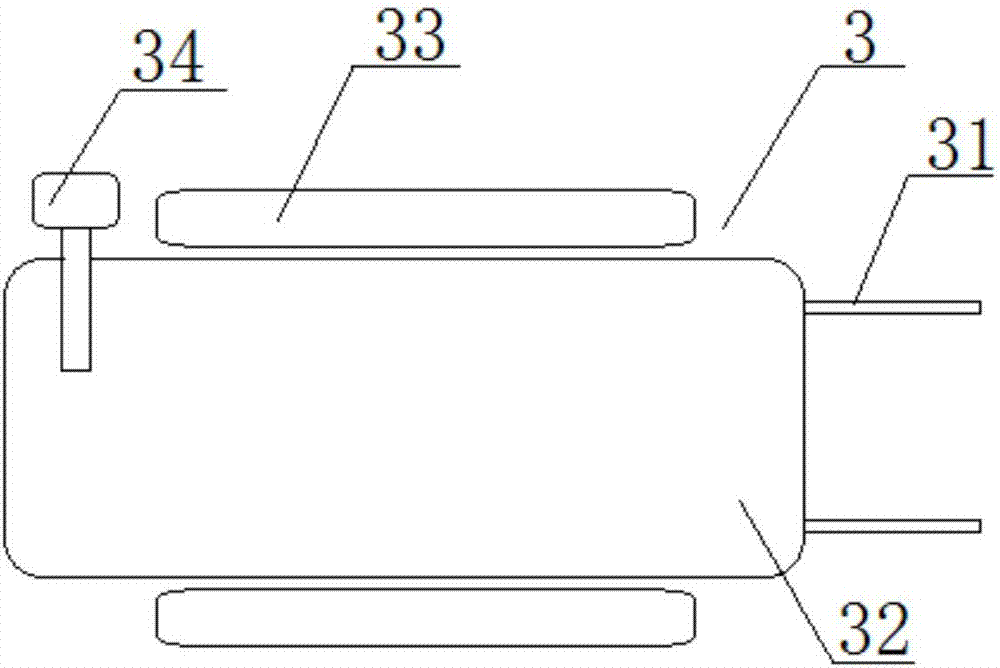

[0057] The calcium-zinc composite stabilizer production system of present embodiment, basic structure is the same as embodiment 2, difference and improvement are: described drying device 3 is vacuum freeze-drying device, as image 3 As shown, the vacuum freeze-drying device includes an inlet and outlet guide rail 31, a freeze-drying bin 32, a cold trap 33 and a vacuum pump 34; the inlet and outlet guide rail 31 is connected to the built-in guide rail of the freeze-drying bin 32; the cold trap 33 is placed outside On one side of the freeze-drying warehouse 32, the two are communicated through pipelines; the vacuum pump 34 is also communicated with the freeze-drying warehouse 32 through pipelines.

[0058] The calcium-zinc composite stabilizer of the present embodiment, basic batching is the same as embodiment 1, difference and improvement are: the component of its batching comprises calcium stearate and zinc stearate each 35 parts by weight, each 10 parts by weight of Paraffin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com