Technology and device forsynthesizingmethanol

A methanol synthesis, methanol technology, applied in the preparation of organic compounds, bulk chemical production, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

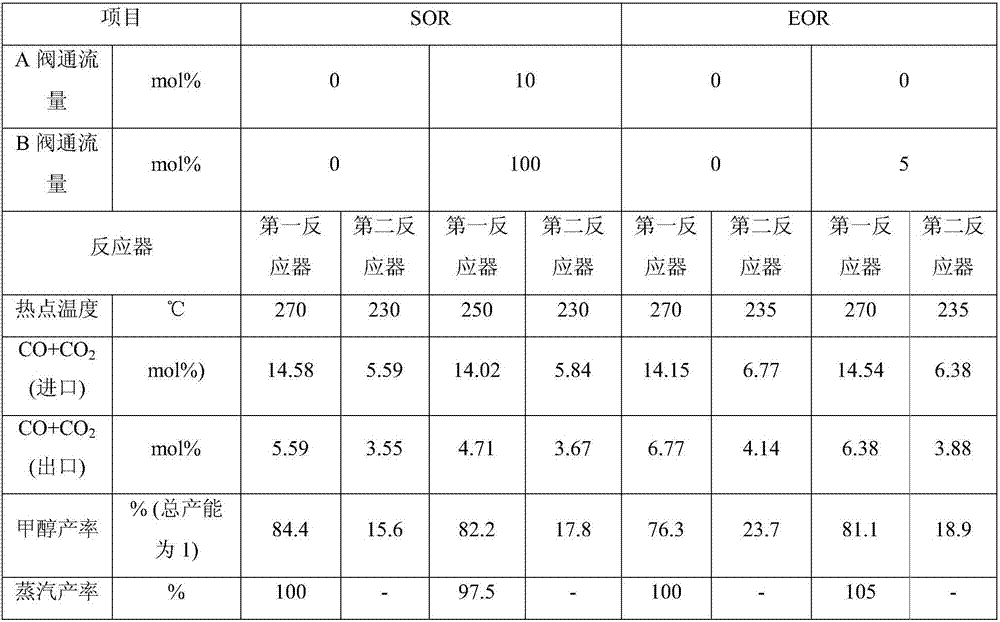

Embodiment 1

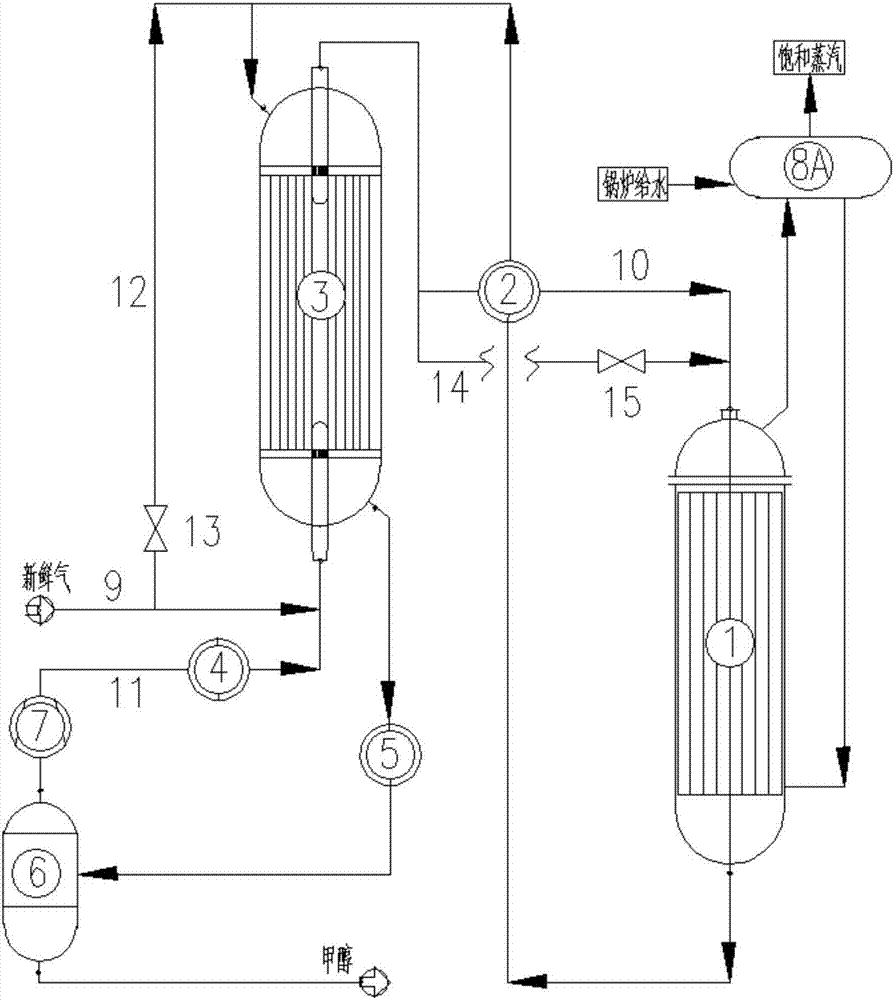

[0038] Such as figure 1 As shown, a methanol synthesis device includes a fresh gas conduit 9, a first reactor inlet conduit 12, a first reactor 1, a first gas-gas heat exchanger 2, a second reactor 3, a cooler 5, Methanol separator 6; the gas outlet of the first reactor 1 is connected to the gas inlet of the second reactor 3 through the first gas-gas heat exchanger 2, and the gas outlet of the second reactor 3 is connected to the gas outlet of the second reactor 3 through the cooler 5 The air inlet of the methanol separator 6 is connected, and the gas outlet of the methanol separator 6 is provided with a synthesis gas circuit 11, and a synthesis gas cycle machine 7 and a second gas-gas heat exchanger 4 are successively arranged on the synthesis gas circuit 11. The gas outlet end of the gas conduit 9 is connected to the synthesis gas circuit 11 so that the fresh gas merges with the methanol-separated synthesis gas after the second gas-to-gas heat exchanger 4 has heated up, and ...

Embodiment 2

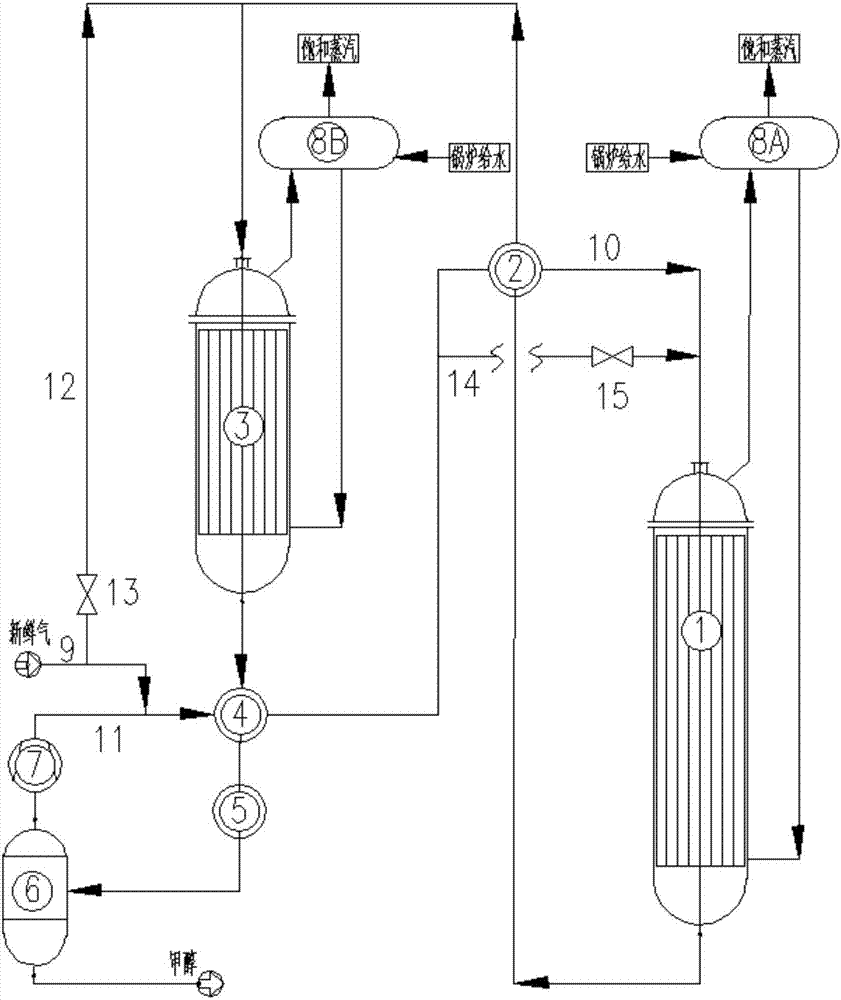

[0049] Such as figure 2 As shown, a methanol synthesis device includes a fresh gas conduit 9, a first reactor inlet conduit 12, a first reactor 1, a first gas-gas heat exchanger 2, a second reactor 3, a cooler 5, Methanol separator 6; the gas outlet of the first reactor 1 is connected to the gas inlet of the second reactor 3 through the first gas-gas heat exchanger 2, and the gas outlet of the second reactor 3 passes through the island two gas successively. The gas heat exchanger 4 and the cooler 5 are connected to the inlet of the methanol separator 6, the gas outlet of the methanol separator 6 is provided with a synthesis gas circuit 11, and a synthesis gas cycler 7 is provided on the synthesis gas circuit 11, fresh The gas outlet end of the gas conduit 9 is connected to the synthesis gas circuit 11 so that the fresh gas merges with the synthesis gas after methanol separation. The connection position between the fresh gas conduit 9 and the synthesis gas circuit 11 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com