A kind of spherical activated carbon and preparation method thereof

A spherical activated carbon and spherical technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problems of high cost, complex process, irregular shape, etc., and achieve high carbonization efficiency, simple process, and surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

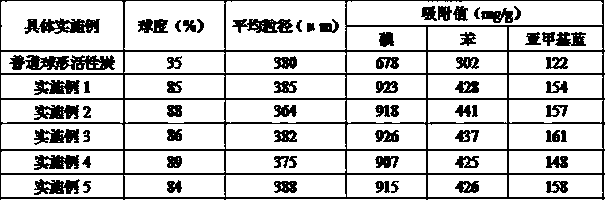

Examples

Embodiment 1

[0030] A spherical activated carbon and a preparation method thereof. The specific process for preparing the spherical activated carbon is as follows:

[0031] Split the bamboo into 30~50mm long bamboo strips with a width of 3~5mm, dry naturally, and then pulverize with a micro-pulverizer. Take 10kg of bamboo powder with a particle size of 40~60 mesh, place it in an electric rotary cooking pot, add 40kg Sulfate solution with a mass concentration of 10%, first run idling for 20 minutes, then heat up to 165°C, heat up and cook for 60 minutes, and then pressurize at this temperature to 0.7MPa and pressure for 120 minutes to obtain mature bamboo Pulp; mix the bamboo pulp micropowder with 3kg spherical barium sulfate, add 1.5kg phosphoric acid, and place in a kneader, set the fast blade speed to 42r / min, the slow blade speed to 28r / min, and the kneading temperature to 95°C. The kneading time is 1.5h to obtain a spherical material with inorganic spherical micropowder as the core and ba...

Embodiment 2

[0034] A spherical activated carbon and a preparation method thereof. The specific process for preparing the spherical activated carbon is as follows:

[0035] Split the bamboo into 30~50mm long bamboo strips with a width of 3~5mm, naturally air-dry, and then pulverize with a micro grinder. Take 10kg of bamboo powder with a particle size of 40~60 mesh, place it in an electric rotary cooking pot, and add 50kg Sulfate solution with a mass concentration of 10%, run idling for 10 minutes, then rise to 160°C, the heating and cooking time is 80 minutes, and then pressurize to 0.6MPa at a constant temperature at this temperature, and the pressure cooking time is 100 minutes to obtain mature bamboo Pulp; mix the bamboo pulp with 3.6kg of glass beads, add 1.8kg of phosphoric acid, and place it in a kneader. Set the fast blade speed to 35r / min, the slow blade speed to 24r / min, and the kneading temperature to 100°C. The kneading time is 1.5h to obtain a spherical material with inorganic sph...

Embodiment 3

[0038] A spherical activated carbon and a preparation method thereof. The specific process for preparing the spherical activated carbon is as follows:

[0039] Split the bamboo into 30~50mm long bamboo strips with a width of 3~5mm, dry naturally, and then pulverize with a micro grinder. Take 10kg of bamboo powder with a particle size of 40~60 mesh, place it in an electric rotary cooking pot and add 60kg Sulfate solution with a mass concentration of 10%, run idling for 15 minutes, then heat up to 170°C, heat up the cooking time for 70 minutes, and then press at this temperature to constant temperature and pressurize to 0.7MPa, pressure cooking time for 110 minutes, to obtain mature bamboo Pulp; mix the bamboo pulp with 4.2kg ceramic microspheres, add 2.8kg phosphoric acid, and place it in a kneader. Set the fast blade speed to 42r / min, the slow blade speed to 28r / min, and the kneading temperature to 90°C. The kneading time is 1.2h to obtain a spherical material with inorganic sphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com