Arm fracture security supporting device

A safety support and boom technology, applied in safety devices, transportation and packaging, load hanging components, etc., can solve the problems of hidden dangers to the safety of construction workers, casualties, damage and other problems, and reduce casualties and property losses. Guaranteed smooth, well-structured results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

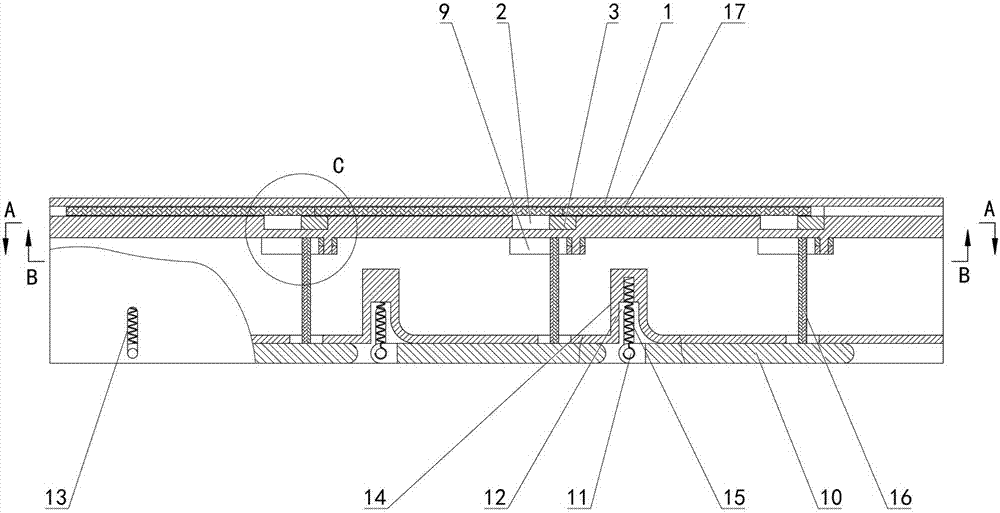

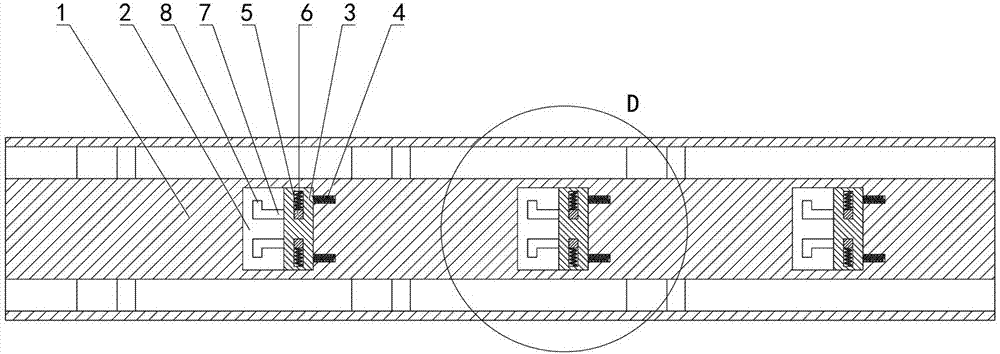

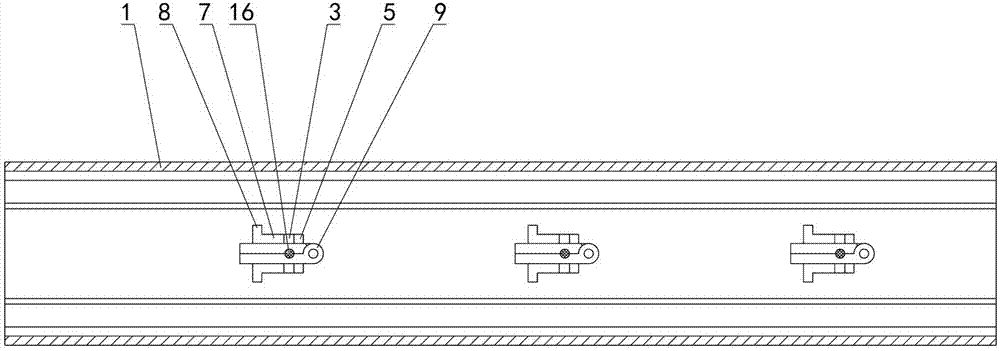

[0018] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Depend on Figure 1 to Figure 6 Given, the present invention comprises the boom 1 that is arranged horizontally and transversely, the upper end surface of the boom 1 is provided with a plurality of chutes 2 distributed along the length direction of the boom 1, and the chute 2 is equipped with a device that can slide left and right in the chute 2 The slide block 3, the right side of the slide block 3 has the first tension spring 4 placed in the chute 2 and arranged horizontally, one end of the first tension spring 4 is connected with the slide block 3, and the other end of the first tension spring 4 is connected with the The boom 1 is connected to form a structure in which the slider 3 slides to the right in the chute 2 through the first tension spring 4;

[0020] Two clamping blocks 5 arranged side by side on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com