Intelligent screening method for metal flakes

A technology of metal flakes and screening methods, which is applied in the field of screening, can solve the problems of increased cost, high scrap rate of metal flakes, and waste products produced by metal flakes, so as to prevent mutual collision and improve the pass rate of screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and preferred embodiments, but the embodiments of the present invention are not limited thereto.

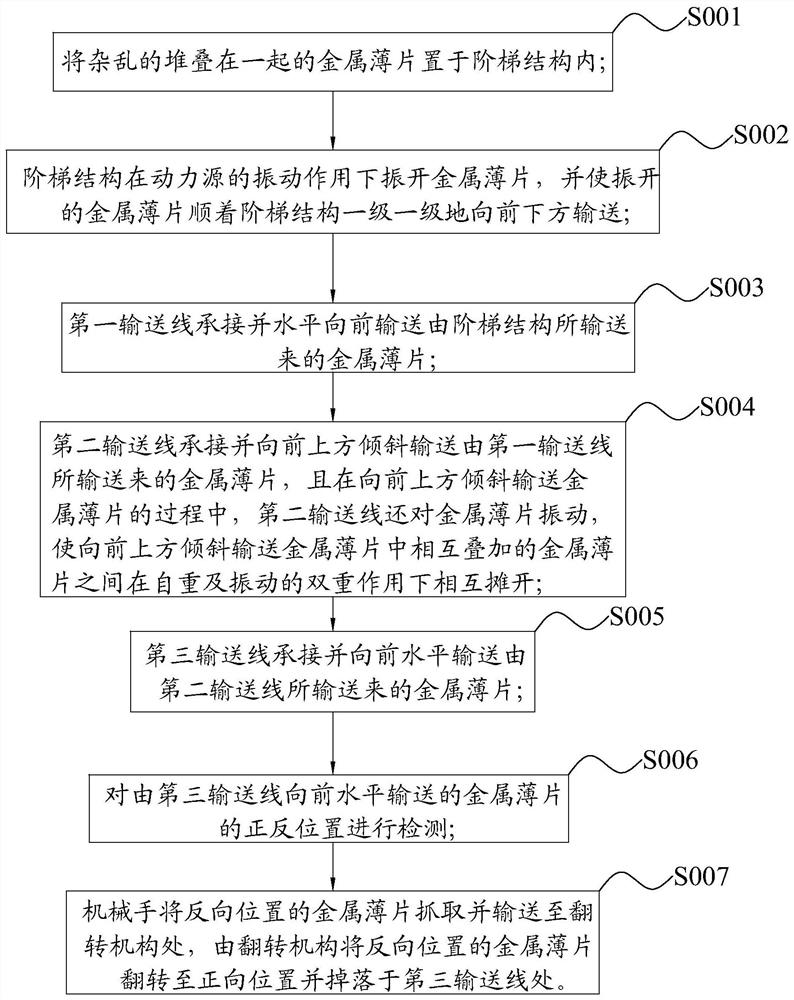

[0019] see figure 1 , the intelligent screening method for metal flakes of the present invention is suitable for screening disorderly stacked metal flakes, comprising the steps of: S001, placing the disorderly stacked metal flakes in a ladder structure, and carrying the disorderly For the metal sheets stacked together, preferably, the metal sheets are a mobile phone shield, but not limited thereto. S002. The stepped structure vibrates the metal sheet under the vibration of the power source, and the vibrated metal sheet is conveyed forward and downward along the stepped structure step by step; specifically, in this embodiment, the power source is vibration A motor or a vibrating cylinder to simplify the structure of the power source, but not limited thereto. S003. The first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com