Energy absorbing device of coupling-necking and spalling-deformation

An energy-absorbing device and necking technology, which is used in transportation and packaging, railway car body parts, railway vehicle wheel guards/buffers, etc., can solve problems such as deformation and instability, and achieve stable plastic deformation, stable impact force, The effect of enhancing the ability to absorb shock kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

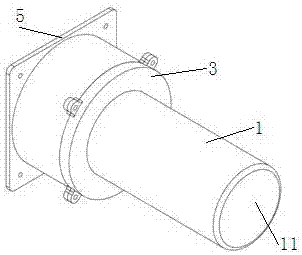

[0034] see Figure 1 to Figure 11 As shown, an embodiment of an energy-absorbing device coupling necking and expansion crack deformation of the present invention includes a mounting base 5, a guide rod 2, a bulging boss 4, a necking flange 3 and a necking deformation tube 1, and the guide rod 2. One end is inserted into the guide through hole 55 provided on the installation base 5, and the bulging boss 4 is sleeved on the guide rod 2 through the guide hole 45 provided in the middle and is located in the installation cavity of the installation base 5. The necking deformation tube 1 is sleeved on the guide rod 2, and the mouth of the small-diameter tube 13 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com