Flame wire printing machine structure

A line printing machine and flame technology, which is applied in the field of medical device product line printing machines, can solve the problems of uniform heating of barrels of cylindrical plastic instruments, etc., to achieve enhanced competitiveness, increased production efficiency, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

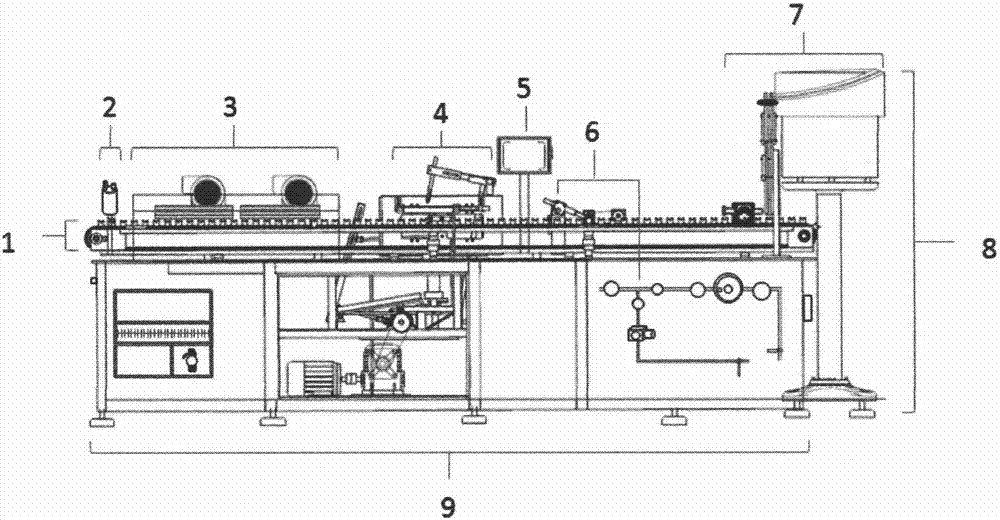

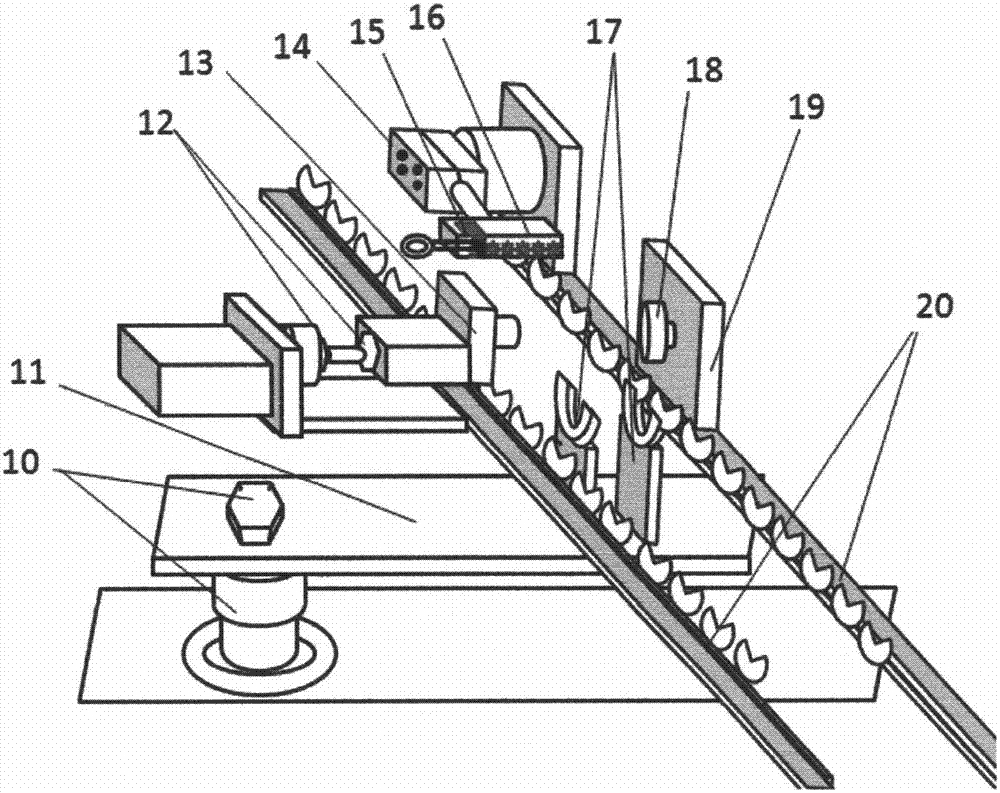

[0017] In order to describe the structure and characteristics of the present invention in more detail, an embodiment is given below in conjunction with figure 1 figure 2 Describe the structure of a flame marking machine of the present invention.

[0018] figure 1 The flame marking machine shown includes a conveyor chain system 1, a silicone oil injection system 2, a heating lamp drying system 3, a printing system 4, a digital control panel 5, a flame system 6, a feeding system 7, and a vibration feeder 8. The flame structure 6 is placed in the previous process of the printing system 4 .

[0019] figure 2 In the schematic diagram of the flame structure of the line printing machine shown, debugging is carried out before printing, the drum is placed on 17, and the height of the drum supported by 17 is adjusted through 10, so that the highest lifting point of the drum can be matched with the thimble in 13. , 18 are in the same horizontal plane. Through 12 optimize the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com