Welding device, welding system and welding method for pipes

A pipe fitting welding and pipe fitting technology, which is applied in the direction of welding/welding/cutting items, auxiliary devices, welding equipment, etc., can solve the problems of cumbersome and unfavorable welding, and achieve the effect of avoiding cable interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

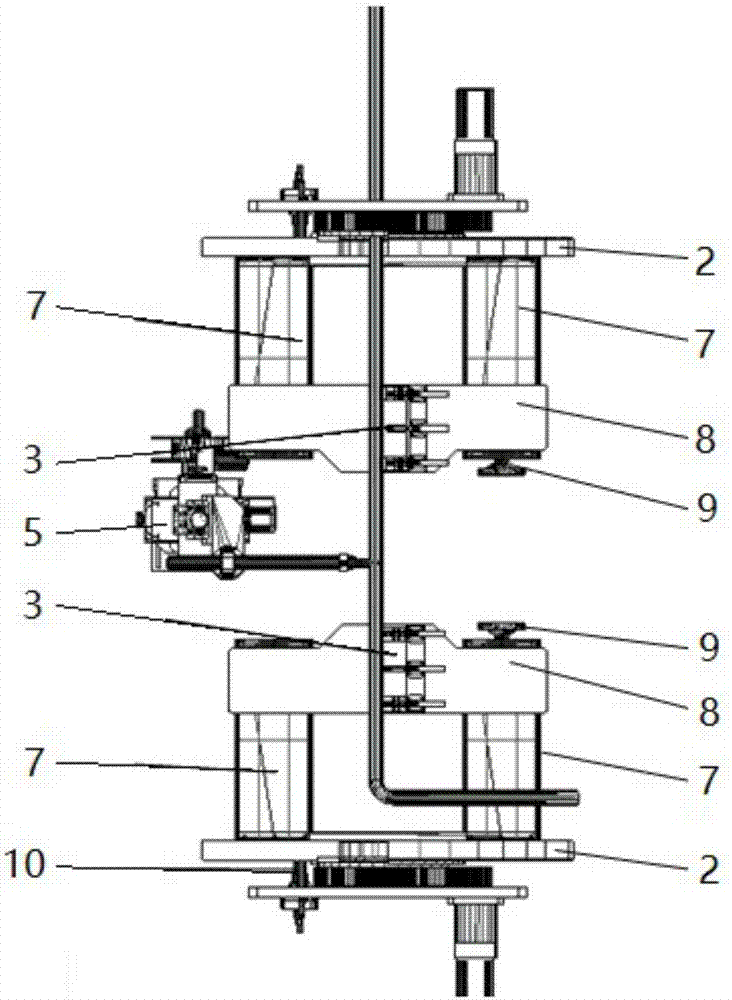

[0056] Such as figure 1 As shown, the first embodiment provides a welding device for pipe fittings, which includes two sets of rotatable workbenches 2 and a welding assembly 5, and uses two sets of rotatable workbenches 2 to drive the pipe fittings 12 to rotate infinitely, avoiding the need for cables during welding Without interference, barrier-free welding of the pipe fitting 12 can be realized.

[0057] In the first embodiment, two sets of rotatable workbenches 2 are arranged up and down opposite to each other. A set of clamping assemblies 3 are respectively provided on these two sets of workbenches 2, and each set of clamping assemblies 3 is provided with a pipe fitting 12 for clamping. The clamping space, the pipe fittings 12 to be welded can be reliably clamped and fixed in the clamping space, so as to facilitate the subsequent welding process of the pipe fittings 12; 2 are coaxially arranged, that is to say, when two pipe fittings 12 to be welded are respectively clamped...

Embodiment 2

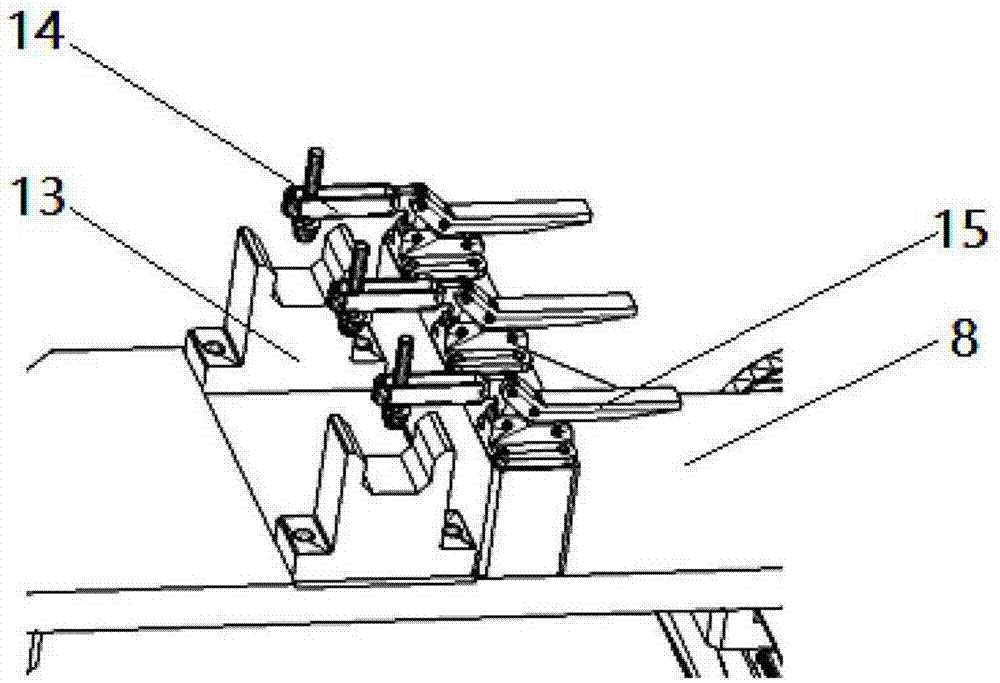

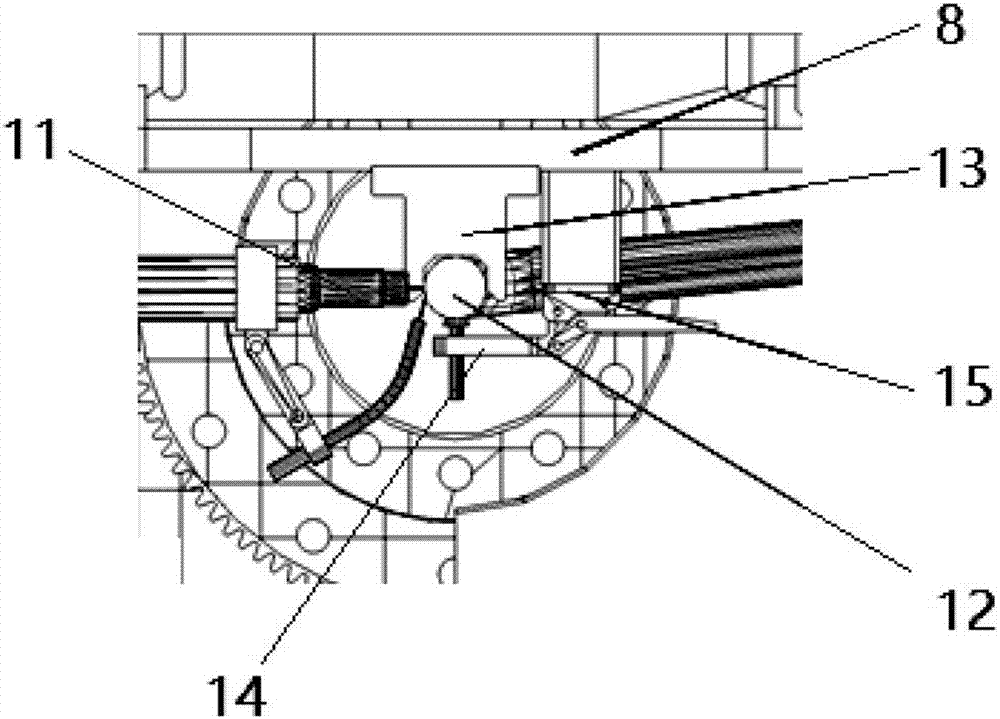

[0072] The structure of the pipe fitting welding device provided in the second embodiment is basically the same as that in the first embodiment, and the similarities need not be repeated. One of the clamping assemblies 3 has the same structure, that is, the clamping assembly 3 includes a clamp 14 and a fixed block 13; and the other set of clamping assemblies 3 includes a chuck fixed on the worktable 2, and the axis of the chuck is provided with There is a clamping space, and at least three claws are respectively arranged around the clamping space, and the pipe fitting 12 to be welded is inserted at the central axis position between each claw, and the claws are pressed from multiple directions, so that the pipe fittings 12 is fixed in the clamping space. This setting is because according to the requirements of the EMU copper tube welding process, when welding between the clip and the copper tube, it is usually impossible to use the method of pressing and clamping up and down at ...

Embodiment 3

[0074] Such as Figure 4 As shown, on the basis of the above-mentioned embodiment 1 or embodiment 2, this embodiment 3 provides a pipe fitting welding system, the frame 1 of the system is fixed with the control device 4 and the above-mentioned pipe fitting welding device, The system uses the control device 4 to control the welding torch 11 of the pipe welding device to weld the rotating pipe 12, the welding assembly 5 is fixed, and the workbench 2 is used to drive the pipe 12 to rotate infinitely, which avoids cable interference during welding and can realize Hassle-free welding of pipe fittings 12.

[0075] Specifically, the control device 4 of the system is connected to the workbench 2 and the welding assembly 5 respectively, and the control device 4 is provided with a workbench 2 control module, a welding torch 11 control module, a wire feeding control module, an arc length tracking module and a data processing module . The workbench 2 control module is respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com