Automatic keyboard disassembling device

An automatic disassembly and keyboard technology, applied in the direction of solid waste removal, electronic waste recycling, recycling technology, etc., can solve the problems of large scrapped keyboards, limited service life, inability to disassemble, etc., and achieve simple and convenient separation and separation efficiency. High, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

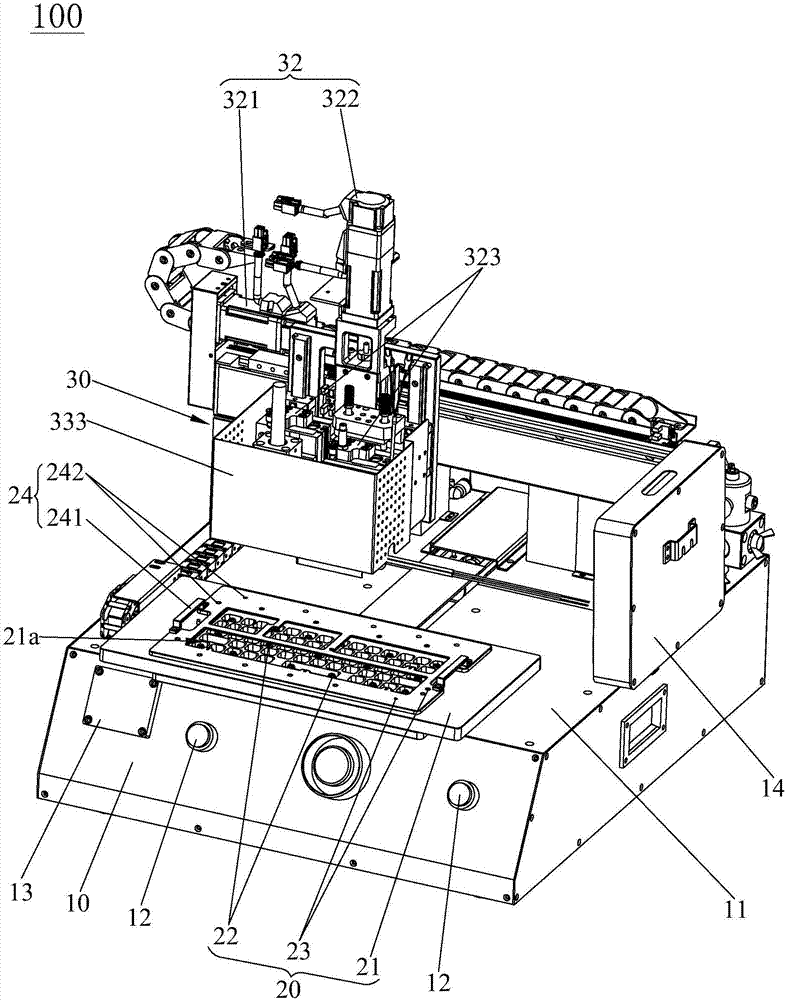

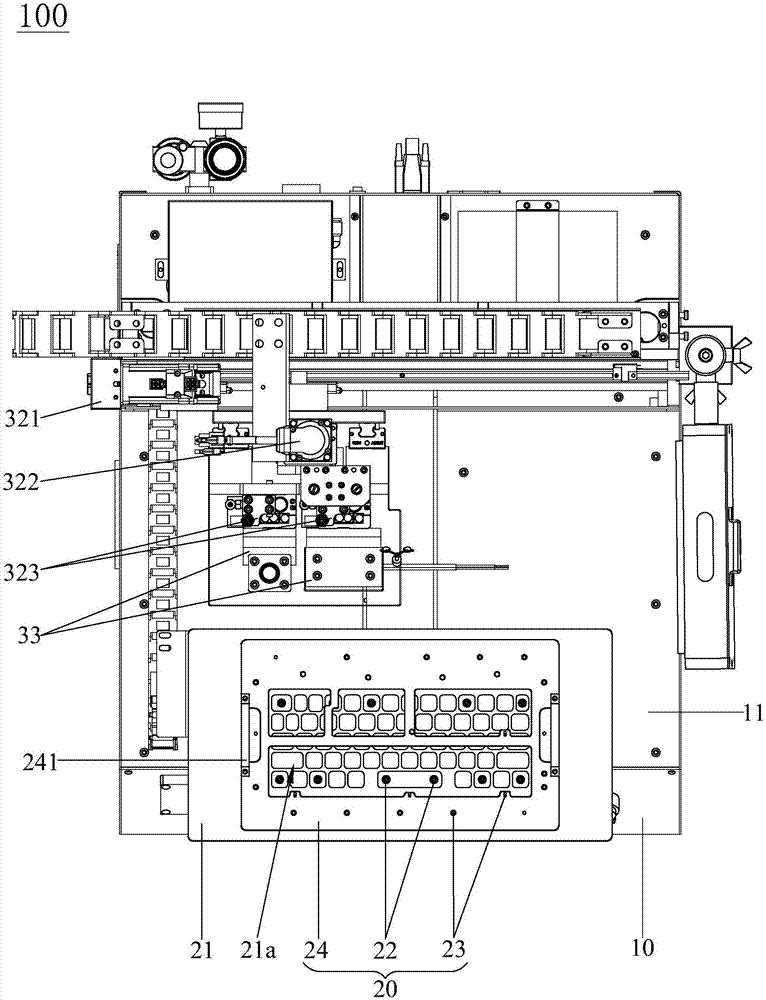

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

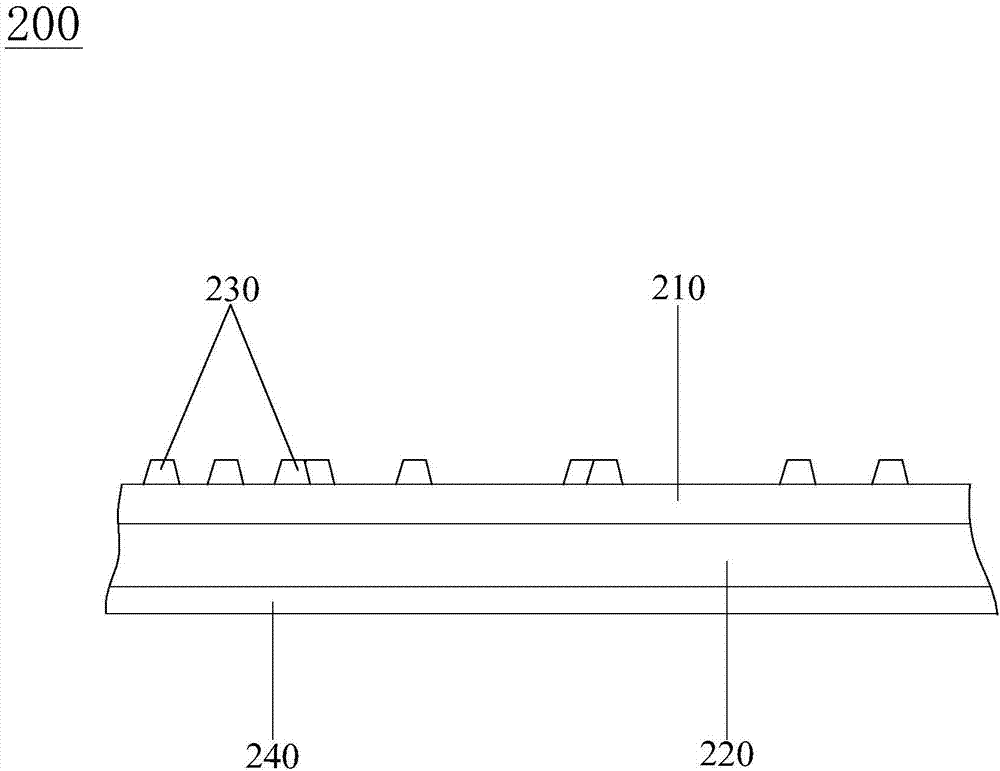

[0023] see figure 1 In the keyboard 200 disclosed in the present application, the circuit board 210 and the outer frame 220 are thermally connected through several irregularly distributed heat-melt pillars 230 , and the number of heat-melt pillars 230 is 87 or 212. Three frames of the outer frame 220 are also connected by hot-melt glue at the edges of the three sides corresponding to the circuit board 210, and the other side of the outer frame 220 opposite to the circuit board 210 is also provided with several buttons ( Not shown in the figure) and a whole piece of cloth 240 covering all the keys, the cloth 240 makes there is no gap between the keys, thereby playing a waterproof and anti-fouling effect. If you want to disassemble the keyb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com