Separation device used after plastic grain cutting

A separation device and granulation technology, applied in the direction of coating, etc., can solve the problems of high plastic toughness, plastic dust, and unsightly appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

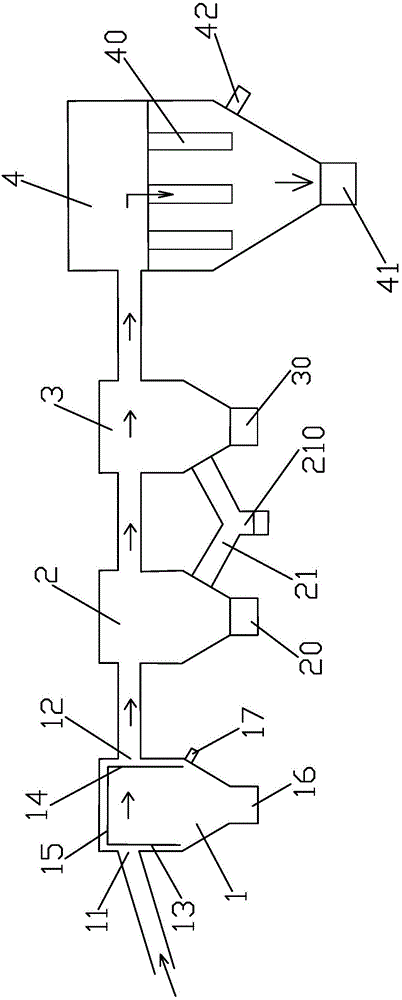

[0016] refer to figure 1 (The arrow in the figure indicates the flow direction of the internal gas when the device is working), a separation device for plastic granulation, including a filter box 1 for filtering granular materials, and the opposite side walls of the filter box 1 are respectively arranged There is a feed port 11 and a discharge port 12 and the filter box 1 is provided with a front filter screen 13 and a rear filter screen 14 between the feed port 11 and the discharge port 12, and the discharge port 12 of the filter box 1 passes through The pipeline is connected with a first material storage box 2, and the other side wall of the first material storage box 2 is provided with a through hole communicating with the second material storage box 3 and the bottom of the first material storage box 2 is provided with a first outlet. A material port 20, the other side wall of the second material storage box 3 is provided with a through hole communicating with the dust coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com