Cleaning equipment of heat-conducting oil system

A technology for cleaning equipment and heat transfer oil, which is applied to cleaning hollow objects, cleaning methods and utensils, separation methods, etc. It can solve problems such as lowering the flash point, affecting the heat transfer effect of heat transfer oil, increasing viscosity, and acid value, so as to prevent clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the present invention will be further described below in conjunction with the examples.

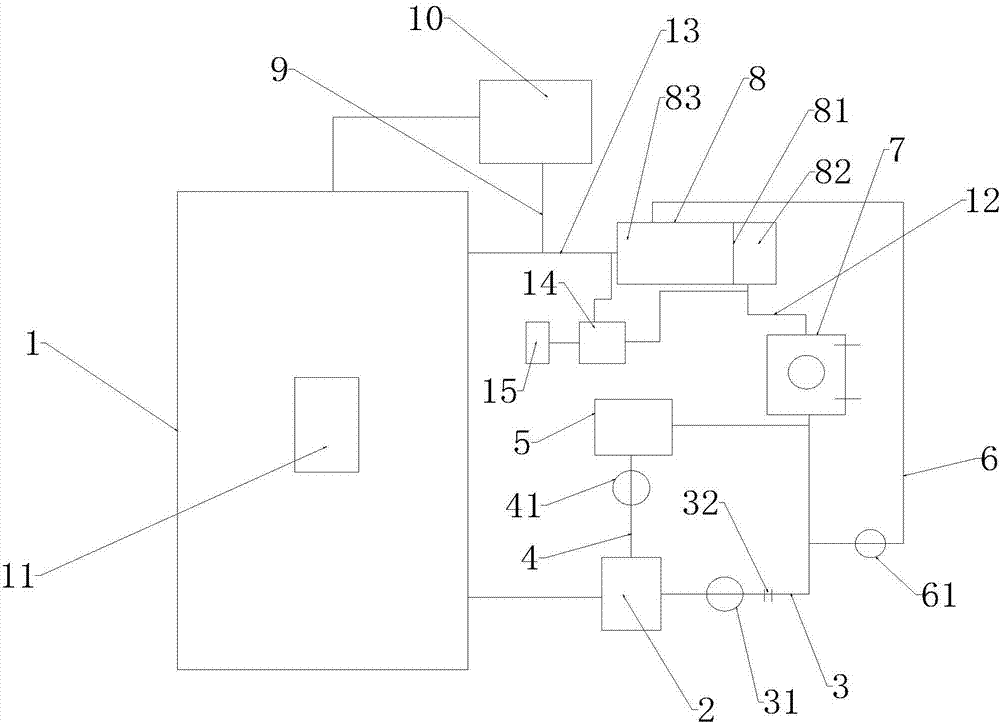

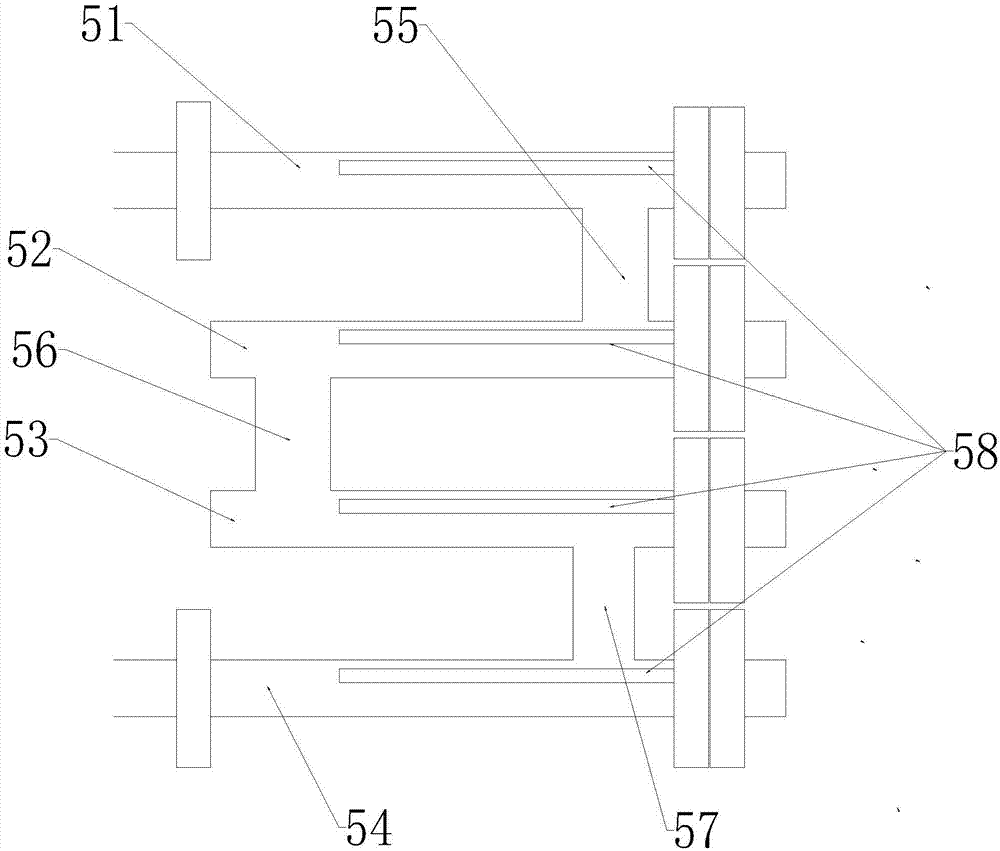

[0028] Such as Figure 1-3 As shown, the heat transfer oil system cleaning equipment includes an equipment system integrated on the base. The equipment system includes an oil storage tank 1 and a forward and reverse flushing switching device 7. The oil outlet of the oil storage tank is connected to the oil outlet pipeline, and the oil outlet pipeline passes through The three-way structure 2 connects the hot oil pipeline 4 and the cold oil pipeline 3. The hot oil pipeline includes a hot oil pipeline connected with the three-way structure. The hot oil pipeline has a first control valve 41, and the cold oil pipeline has a second control valve 31. , the hot oil pipeline and the cold oil pipeline are connected to the inlet port 73 on the forward and reverse flushing switching device, and the forward and reverse flushing switching device includes a first th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com