Transmission mechanism applicable to double-rotation coating mixing machine

A transmission mechanism and mixer technology, applied to mixers with rotating containers, mixers with rotating stirring devices, mixers, etc., can solve the problems of increased production costs and failure rates of machines, and achieve simple structure , reduce failure rate and production cost, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

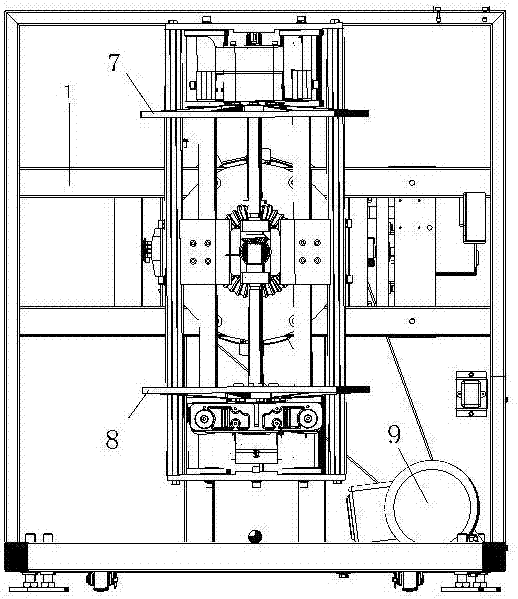

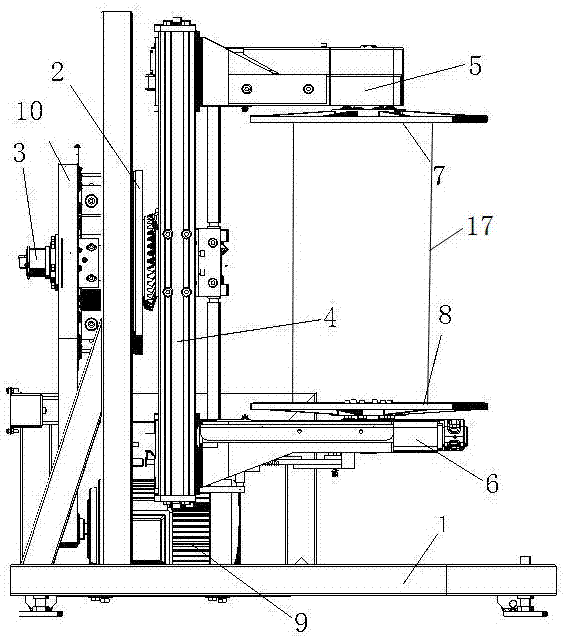

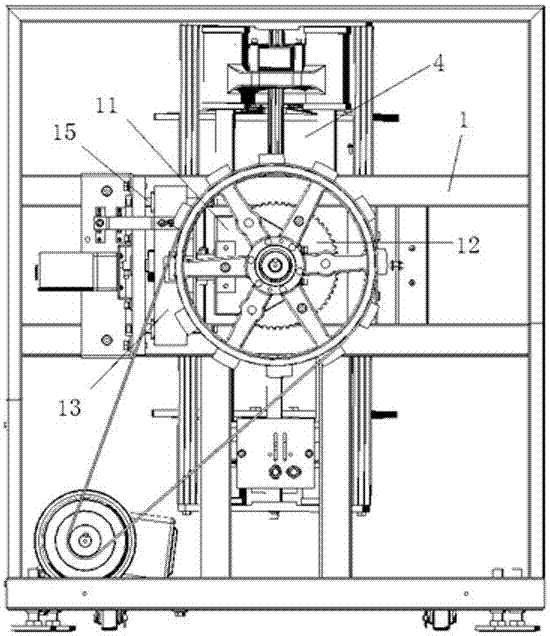

[0028] Example 1, such as Figure 1-7 As shown, when the paint bucket 17 needs to be compressed, a code disc for measuring the position and rotating speed is installed on the driving wheel 10 at the same time, and the rotational position and rotating speed of the driving wheel 10 are measured by the code disc, and the push block 3 is controlled to start moving forward at an appropriate time. move. The driving mechanism on the frame 1 is driven by pneumatic push rod, hydraulic push rod, electric push rod or motor worm to push the push block 13 to press the locking block 11 forward on the slide rail 15. At this time, the rotary main shaft 2 is locked, and the push Block 13 compresses the locking block 11, and the return spring 16 end between the locking block 11 and the shifting gear rod 14 is pressed on the locking block 11 by the pushing block 13, and the other end of the shifting gear rod 14 is connected to the locking gear. 12 separates, and the rotary main shaft 2 can not ...

Embodiment 2

[0030] Example 2, such as Figure 8 As shown, the position of the locking gear 12 is set on one side of the driving wheel 10, the locking gear 12 is set as an external gear, and the working position of the gear rod 14 is set to be consistent with that of the locking gear 12, the above actions can also be completed .

Embodiment 3

[0031] Example 3, such as Figure 9 As shown, the position of the locking gear 12 is set on one side of the driving wheel 10, the locking gear 12 is set as an internal gear, the working position of the shift lever 14 is set to be consistent with the locking gear 12, and the push block 13 is pressed When the locking block 11 is tightened, the gear rod 14 is pressed apart from the internal tooth meshing end of the locking gear 12, and the above-mentioned actions can be completed in cooperation with the above-mentioned components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com