Motor fan housing

A technology of air hood and shroud, which is applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problem of low coaxial accuracy between fan and suction nozzle, aggravate ventilation eddy current noise, and affect motor cooling. Heat dissipation and other problems, to achieve good diversion effect, avoid eddy current, and enhance the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

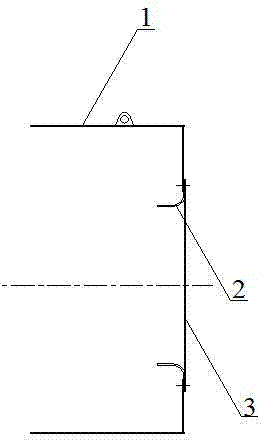

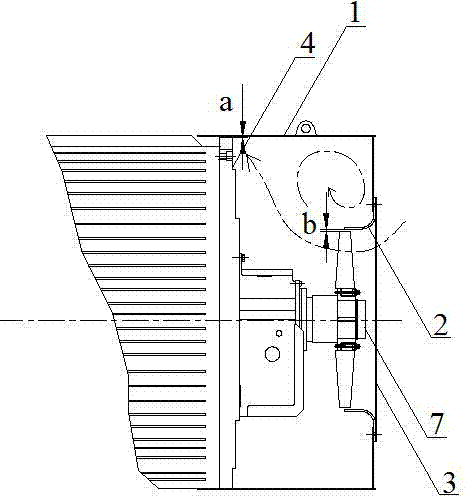

[0044] Such as Figures 1 to 18As shown, a kind of motor fan cover is arranged on the rear end cover 4 of the motor 5, and some straps 16 are evenly distributed on the outer circumference of the rear end cover 4 (the straps are the rear end cover distributed along the outer circumference direction). Several protrusions), the fuselage of the motor 5 is provided with some cooling fins 6 to increase the cooling area and improve the cooling effect of the motor. Described motor wind shield comprises wind shield barrel 1, and wind shield barrel 1 is coaxially provided with conical flow guide cover 12, and flow guide cover 12 adopts perforated plate to be made, and the large-diameter end of described flow guide cover 12 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com