Grid frequency modulation system based on electrode boiler

A technology for electrode boilers and power grids, applied to AC networks with the same frequency from different sources, etc., can solve problems such as frequency fluctuation and system collapse, and achieve the effects of increasing the response rate, prolonging the life of the unit, and increasing the safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

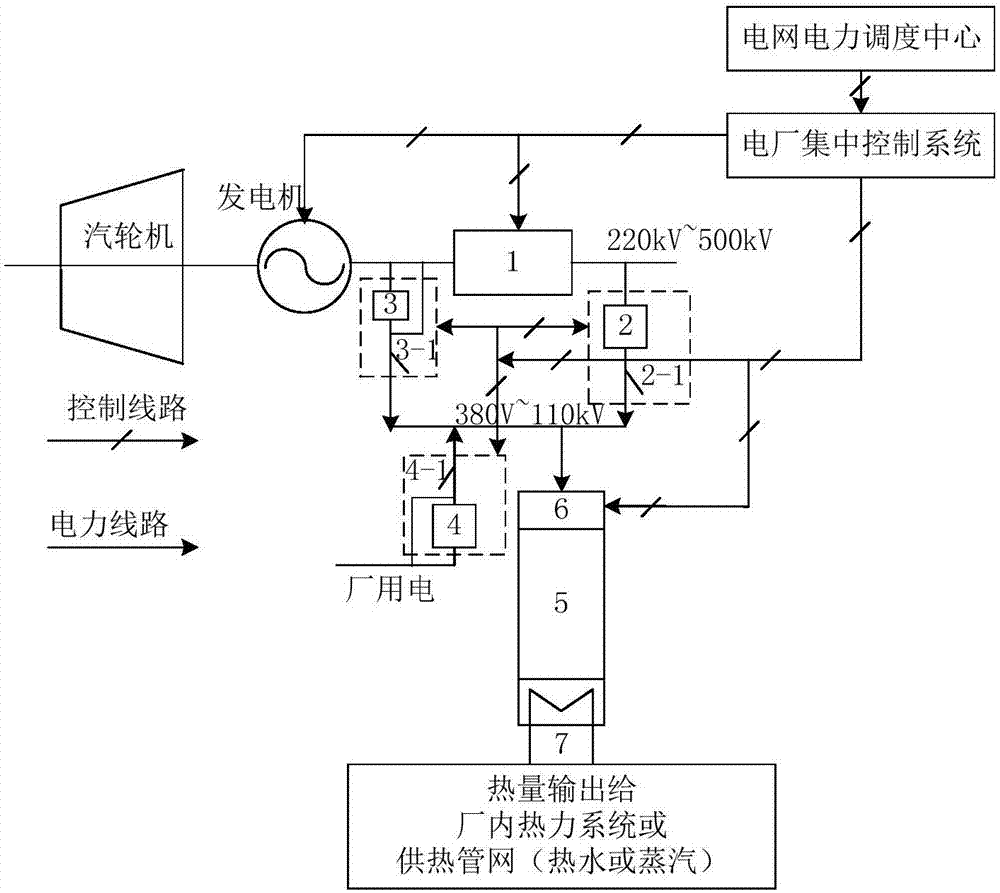

Embodiment 1

[0051] like figure 2 As shown, a power grid frequency regulation system based on electrode boilers, including:

[0052] A frequency modulation control module, including a power grid power dispatching center and a centralized power plant control system, which is connected to the power supply control module and the power control cabinet 6 to control both;

[0053] The power supply control module, whose input end is connected to the output of the power plant, and whose output end is connected to the power control cabinet 6 of the electrode boiler 5, is used to convert the electric energy output by the power plant and then send it to the power control cabinet 6;

[0054] The power control cabinet 6 is used to directly transmit the received voltage, or transmit it to the electrode boiler after being transformed and control the power of the electrode boiler;

[0055] Electrode boilers for converting incoming electrical energy into heat.

[0056] In this embodiment, the power supp...

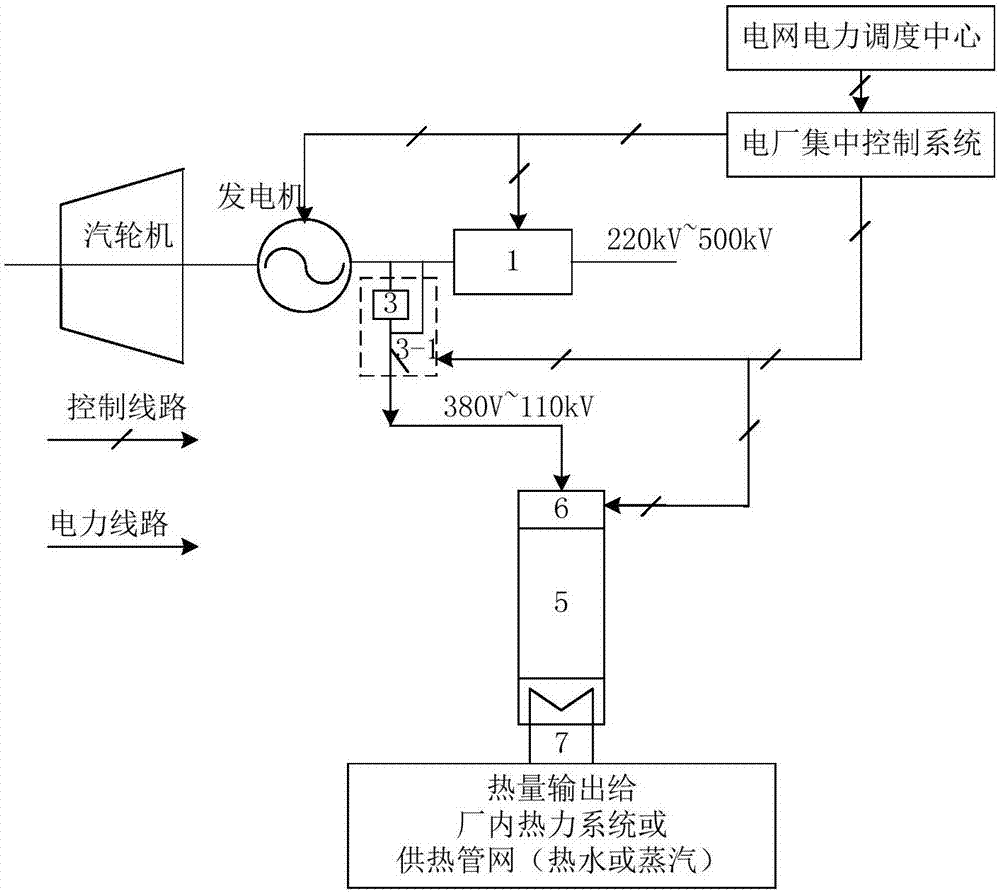

Embodiment 2

[0083] like image 3 As shown, this embodiment is basically the same mechanism as that of the electrode boiler participating in the frequency modulation system described in Embodiment 1, the difference is that the power supply of the electrode boiler is connected at 220kV ~ 500kV after the step-up station of the unit, and then the voltage is reduced through the voltage reducer To 380V ~ 110kV to power the electrode boiler.

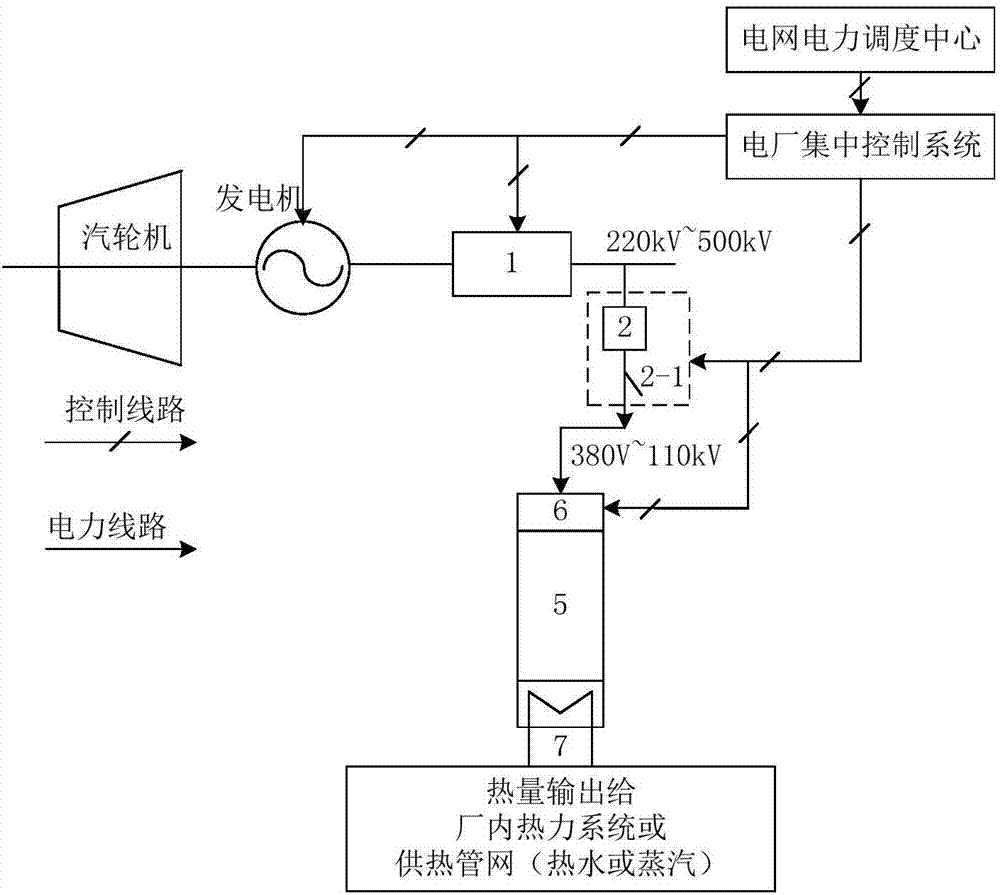

Embodiment 3

[0085] like Figure 4 As shown, this embodiment is basically the same as the mechanism of the electrode boiler participating in the frequency modulation system described in Embodiment 1. The difference is that the power supply of the electrode boiler is connected on the utility line. If the voltage of the utility line is the same as the electrode boiler power supply If the voltage is required to be the same, it can be connected directly through the electrical switch. If the voltage is different, it can be adjusted to 380V ~ 110kV through the transformer to supply power to the electrode boiler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com