Single-pole dual-switch multi-position valve

A multi-position valve and single-lever technology, applied to multi-way valves, valve details, valve devices, etc., can solve the problems of no need for driving, difficulty in adapting to complex working conditions, and bulkiness, and achieve the effect of improving operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

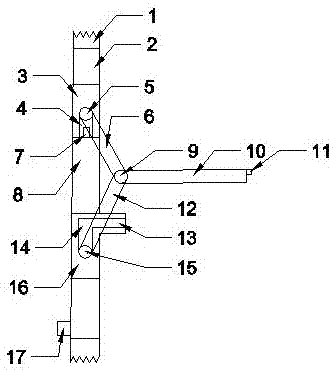

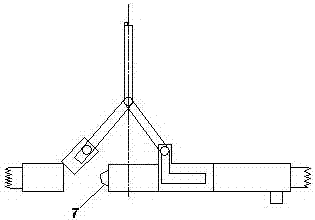

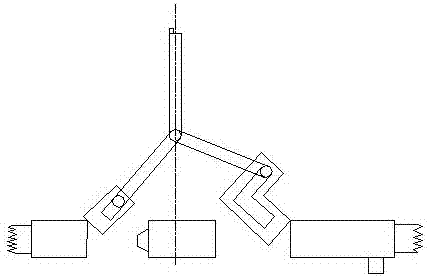

[0020] A single-lever double-open multi-position valve, comprising a valve body, a disc body, a first valve plate, a first slide rail, a first slide pin, a first pole, a contact point, a middle seat, a pivot point, a valve stem, and a transmission pin , the second pole, the second slide rail, the third slide rail, the second sliding pin, the second valve plate, the handle and the driving part; The first opening and the second opening are formed between the outer edges of the disc, the first opening cooperates with the first valve plate, and the second opening cooperates with the second valve plate; the valve stem drives the two valve plates to move, and the top of the valve stem is equipped with a transmission pin , the bottom end of the valve stem is provided with a pivot point, the pivot point is rotationally connected with the first pole and the second pole, the end of the first pole is connected with the first sliding pin, and the first sliding pin is sleeved in the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com