Full-automatic jointed board test tool device

A test device and test fixture technology, which is applied in the direction of measuring device casing, electronic circuit test, printed circuit test, etc., can solve problems such as low efficiency, and achieve the effect of saving time and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are preferred embodiments of the present invention, but the protection scope of the present invention is not limited thereby.

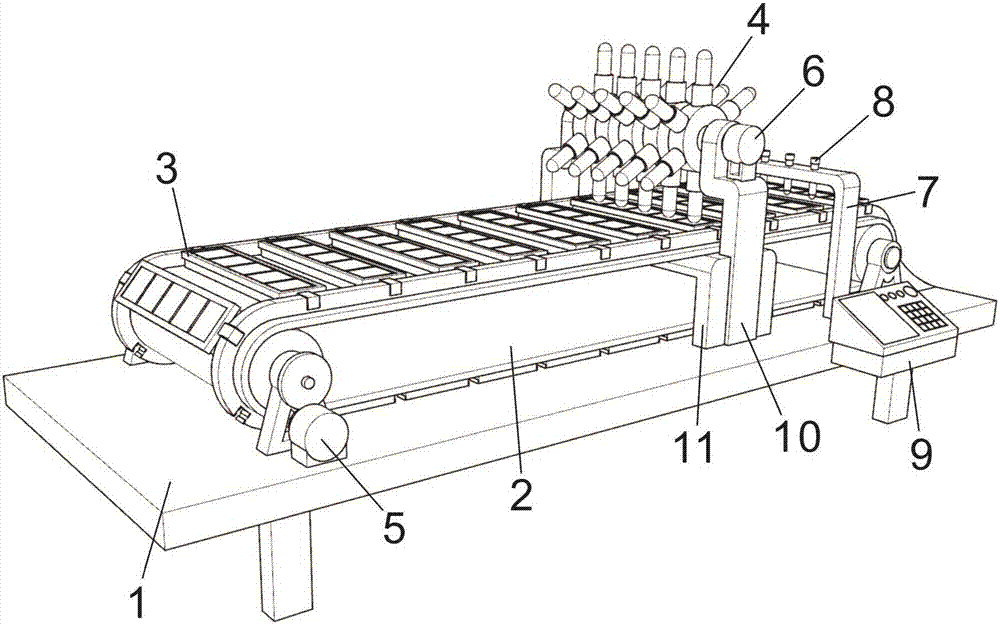

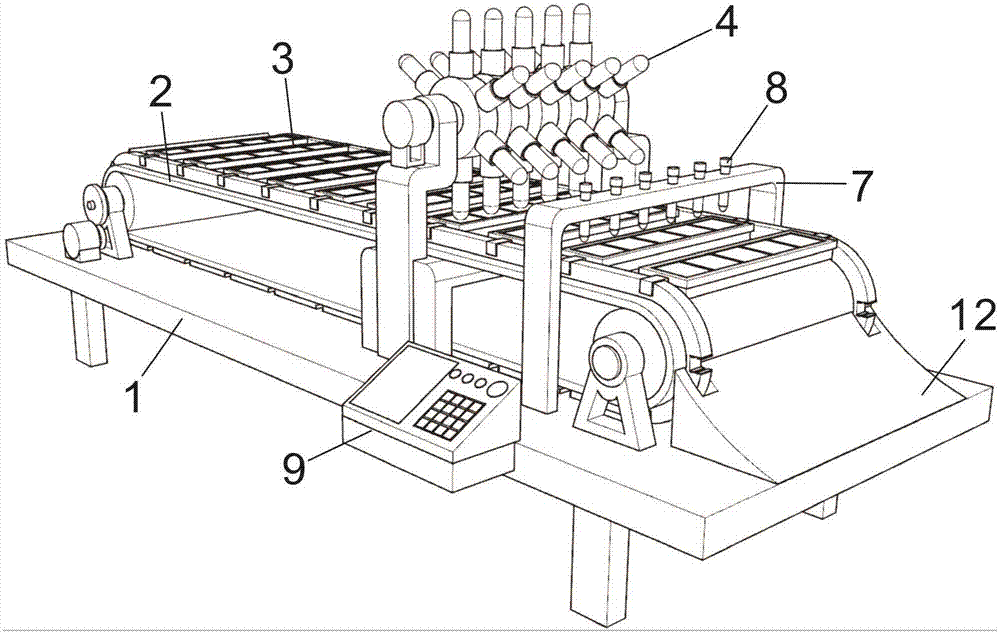

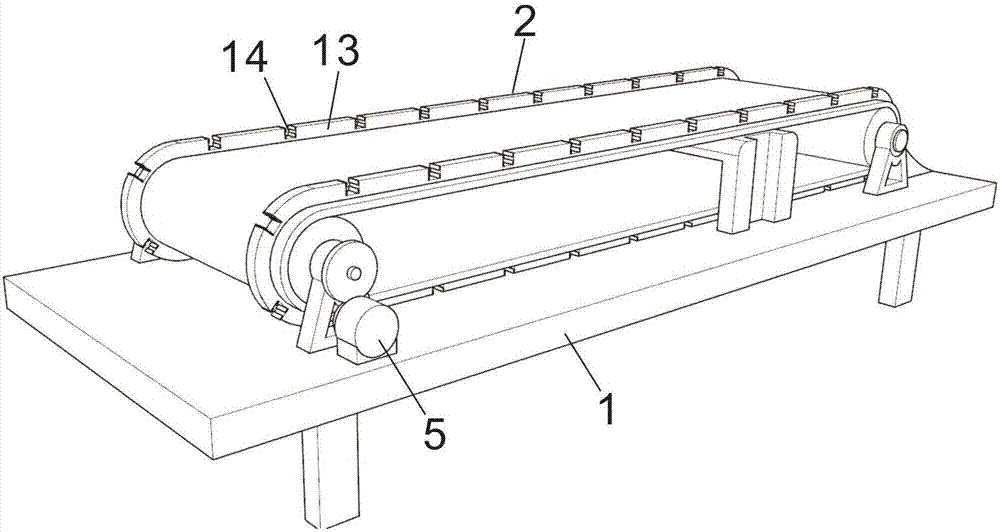

[0019] As shown in the figure, the purpose of the present invention is to provide a fully automatic jigsaw test fixture device, including a table top 1, a transmission belt 2, a jigsaw jig 3, a rolling test device 4, a drive belt driving device 5, and a rolling test device driving device 6. Marking device fixing frame 7, marking device 8, main console 9, support 10, unloading table 12, the transmission belt 2 is installed on the table top 1, the transmission belt 2 is driven by the transmission belt driving device 5, and the jigsaw puzzle Tool 3 is installed on the transmission belt 2; the main console 9 is installed on the table top 1; the rolling test device 4 is located above the transmission belt 2, and is installed on the bracket 10 fixed on the table top 1, and the rolling test device 4 consists of Rolling test device drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com