Method for dispersing nano combustion catalyst in composite propellant

A technology for burning catalysts and propellants, which is applied in the directions of non-explosive/non-thermal agent components, offensive equipment, ammonium perchlorate compositions, etc., can solve the problem of increasing the composite propellant process, high activity of composite particles, and increasing preparation costs, etc. problems, to achieve the effect of increasing the preparation cycle, the dispersion operation cycle is short, and the use risk is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] In a 200mL beaker, add 0.05g Tween-80, 25g diisooctyl sebacate and 25g ethyl acetate, stir with a glass rod to get a solution, then add 5g of nano-combustion catalyst nano-chromous acid to the beaker Copper (d 50 50nm), stirred to make it fully infiltrated, ultrasonicated for 30 minutes to obtain a suspension of nano-combustion catalyst; added the above suspension to the 965g HTPB, AP, Al slurry that had been premixed uniformly, mixed with a kneader for 60 minutes, and heated at 50°C 20min at a vacuum degree of 50KPa, then degassing at a vacuum degree of 10KPa for 40min to remove ethyl acetate to complete the dispersion of the nano-combustion catalyst in the composite propellant, and finally add 5g of curing agent toluene diisocyanate (TDI) to complete the composite propellant Mixing of syrups.

[0015] Performance Testing

[0016] The test instrument is DSCQ200 Thermal Analyzer from TA Company

[0017] Test conditions: heating rate is 5°C / min, test range: room tempe...

Embodiment 2

[0022] The implementation method of this example is basically the same as that of Example 1, except that the surfactant is Tween-20, and the remaining components and their contents are the same as those of Example 1.

[0023] The test method is the same as in Example 1, and the results are shown in Table 3.

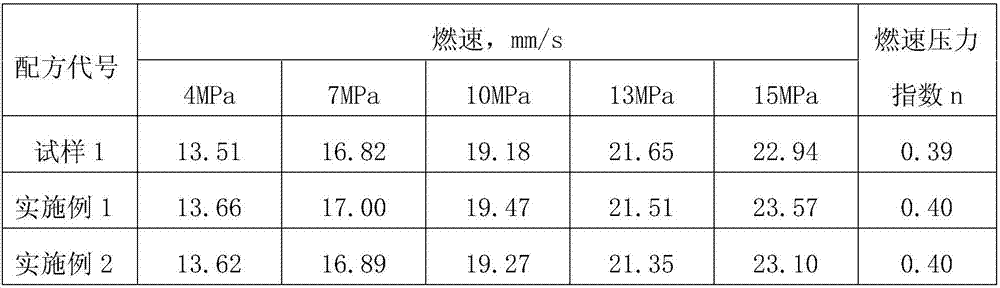

[0024] Table 3 Effect of dispersed nano C.C on propellant burning rate

[0025]

[0026] Above-mentioned result shows, adopts the present invention, nano-C.C / AP mixture thermal decomposition temperature also significantly reduces, is better than comparative method; Utilizes the propellant sample that this method is mixed, and its burning rate is also significantly higher than the non-dispersed containing nano-C.C. Composite propellant sample (sample 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com