Integrated tempering and cleaning frame and tempering and cleaning method for glass

A tempering and integrated technology, applied in the field of glass tempering cleaning and tempering cleaning integrated frame, can solve the problems of high cost, long time-consuming, difficult to pick and place, etc., to reduce the number of fixtures, avoid collision wear, improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

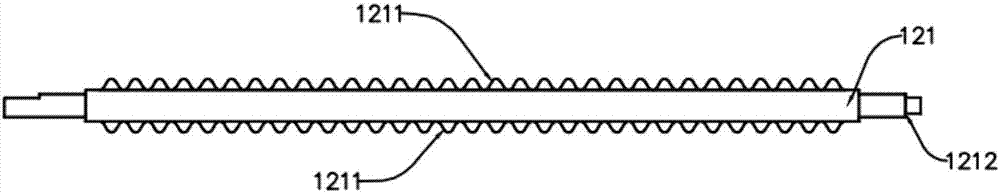

[0049] see Figure 1 to Figure 3 , the present invention discloses a tempered cleaning integrated frame, comprising a main frame 1 and a bracket 2, the bracket 2 is detachably arranged under the main frame 1, the main frame 1 includes a tempered frame main body 11 and a tempered pipe device 12, and the bracket 2 Both ends of the steel frame body 11 are provided with a fixed block 21, the tempered frame body 11 is provided with a slot 111 for inserting the fixed block 21, the slot 111 on the tempered frame body 11 is inserted into the fixed block 21, the entire main frame 1 and the 2 fixed connections. In this embodiment, a plurality of tempered pipe devices 12 are arranged on the tempered frame body 11 at equal intervals. The tempered pipe device 12 includes a tempered upper rack 121, a fixed seat 122 and a tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com