Horizontal automatic garbage compressor

A garbage compressor, horizontal technology, applied in the direction of garbage conveying, garbage collection, loading/unloading, etc., can solve the problems of easy to hang garbage in the collection box, unable to move the host, increase capital investment, etc., to achieve convenient and fast movement and simple structure. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

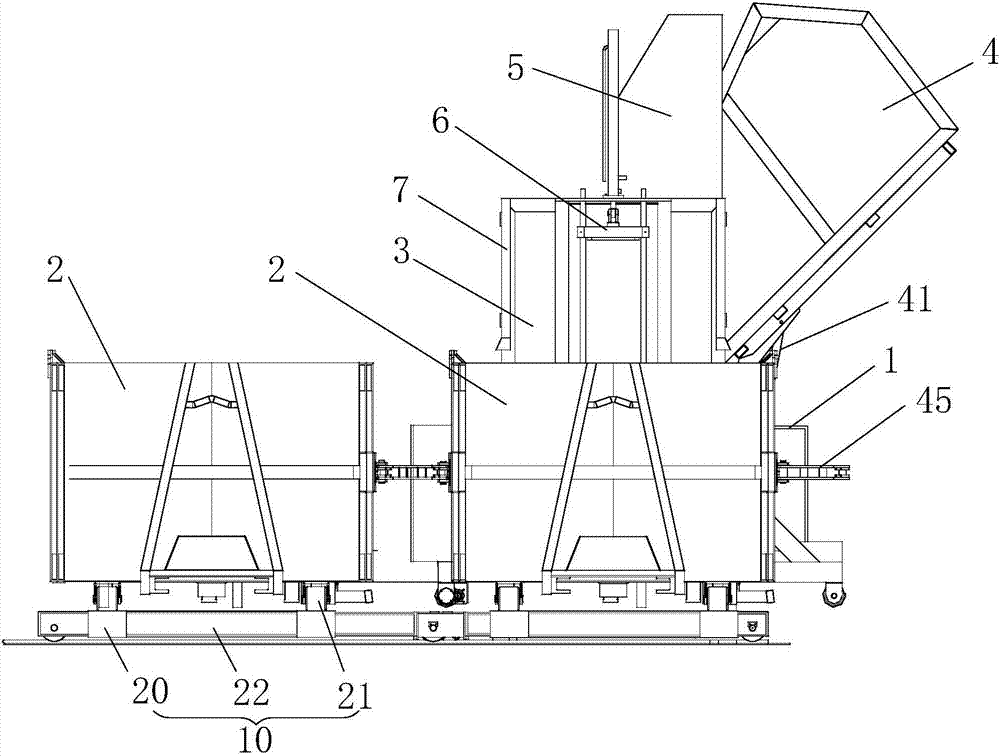

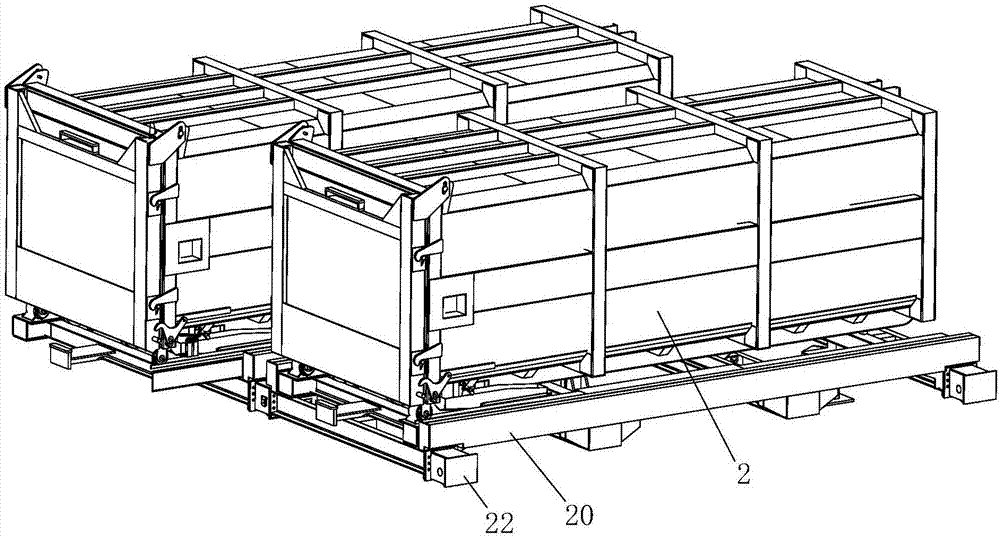

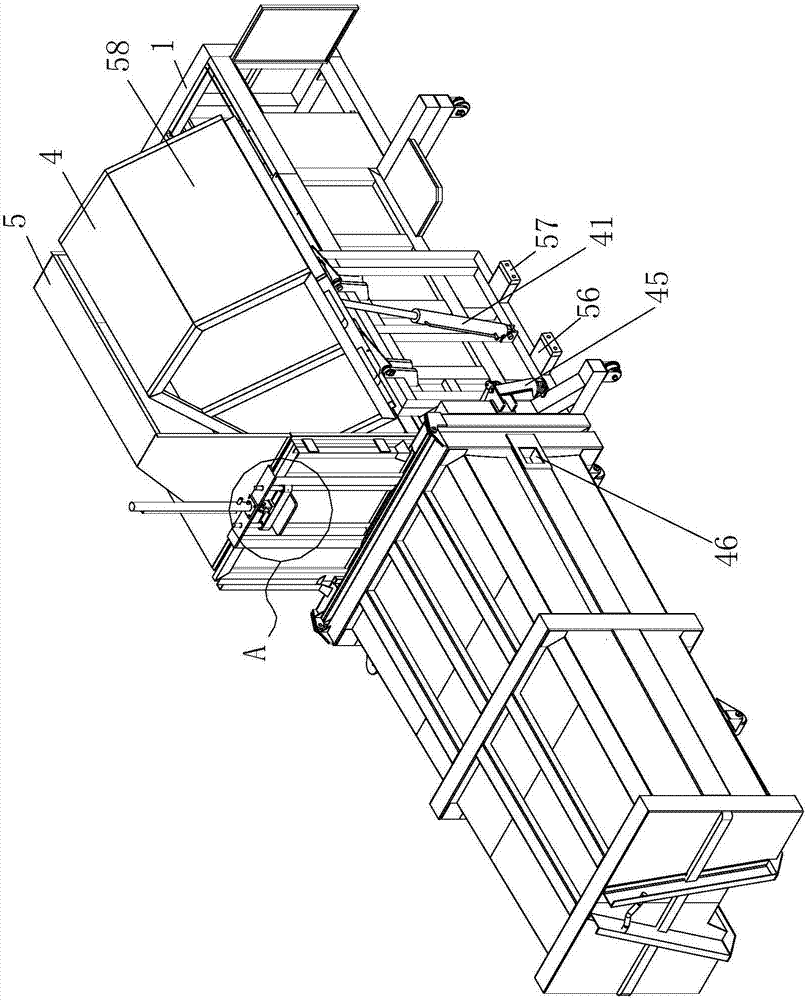

[0038] See Figure 1 to Figure 10 , the present invention has a detachably connected frame 1 and a collection box 2; the inside of the frame 1 has a temporary storage room 3, and one end of the frame 1 near the collection box 2 is hinged with a tipping bucket 4; The hopper cover 5; the temporary storage room 3 is provided with a pushing mechanism for pushing garbage, and the output port of the temporary storage room 3 is provided with a box door pull-in mechanism; the box door pull-in mechanism includes a lifting mechanism 6 and is arranged on the lifting mechanism 6 The left and right box door side guide grooves 7; the collection box 2 includes a box body 8 and a box door 9; the box door 9 is connected to the opening end of the box body 8; There is a tight small door 11 at the end, and the inner edge of the door 9 of the collection box 2 is inlaid with a sealing ring 12; the inner side of the lifting mechanism 6 is provided with a single cylinder door lifting device 13; the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com