Tractor multi-speed steering mechanism

A steering mechanism and tractor technology, applied in the field of tractors, can solve the problems of slow steering speed and large steering radius of tractors, and achieve the effect of low farming skill requirements, small steering radius, and improved farming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

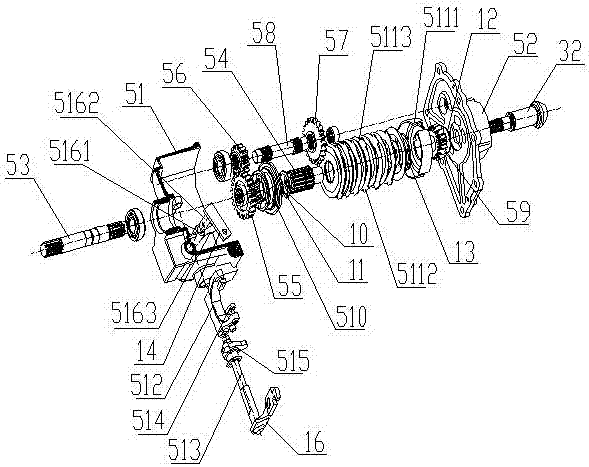

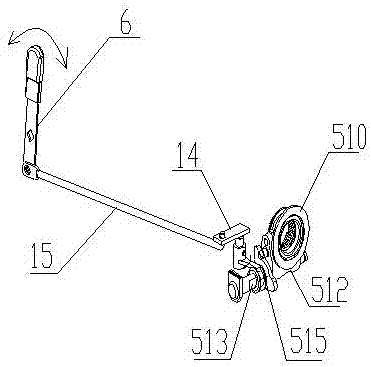

[0024] Example: see Figure 1 to Figure 5 , a tractor double-speed steering mechanism, including a left front wheel 1, a right front wheel 2, a front axle assembly, a steering wheel assembly 4, a double-speed gearbox, and a double-speed joystick 6. The left front wheel 1 and the right front wheel 2 are respectively connected to the two ends of the front axle assembly. The steering wheel assembly 4 is connected with the left front wheel 1 through the front axle steering connecting rod 7, and the left front wheel 1 is connected with the right front wheel 2 through the steering connecting rod 8, so that the steering wheel assembly 4 can drive the left front wheel 1 and the right front wheel Wheel 2 rotates synchronously. The double-speed gearbox includes a box body 51, a case cover 52, a power input shaft 53, a spline connection sleeve 54, a power input gear 55, a double-speed input driving gear 56, a double-speed input driven gear 57, a double-speed transmission shaft 58, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com