Press machine die changing device

A technology of press machine and mold changing trolley, which is applied in the field of mold changing, and can solve the problems of low efficiency of mold changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

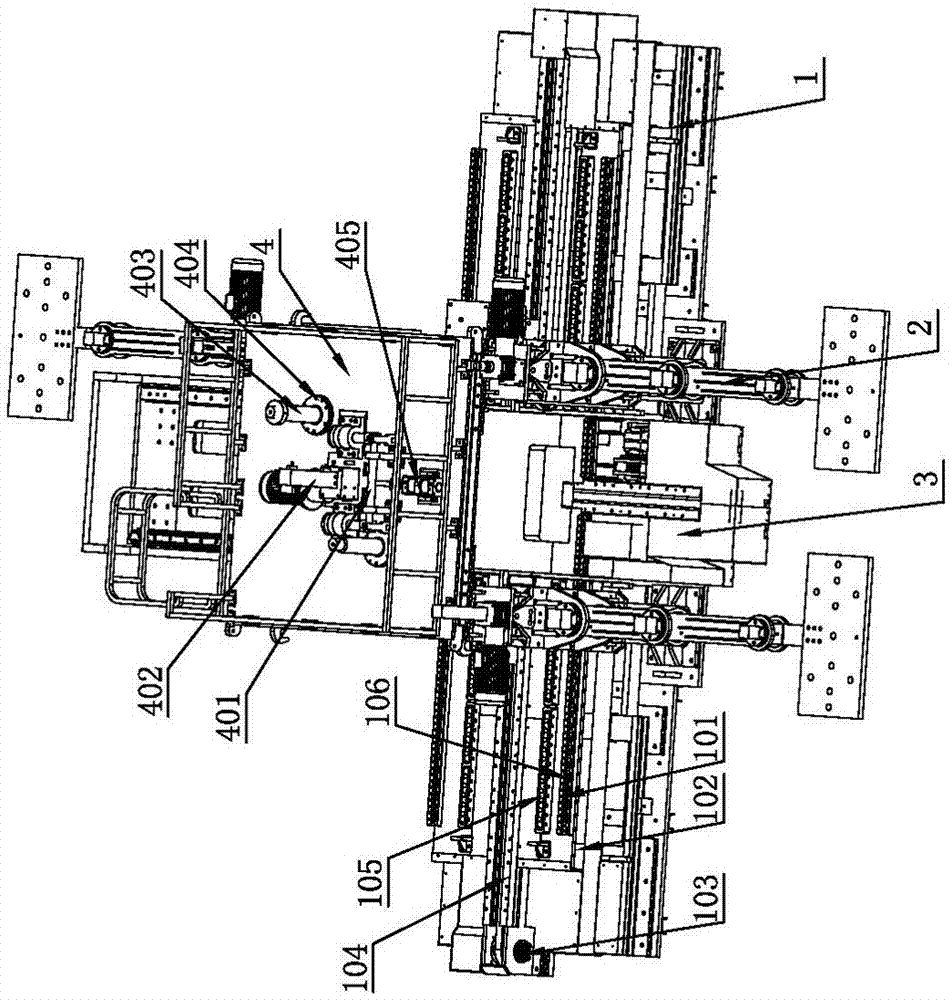

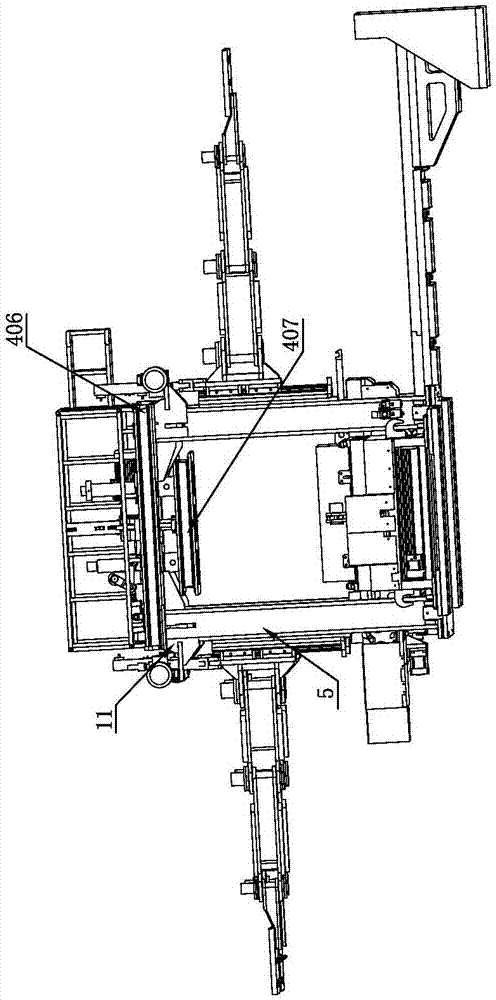

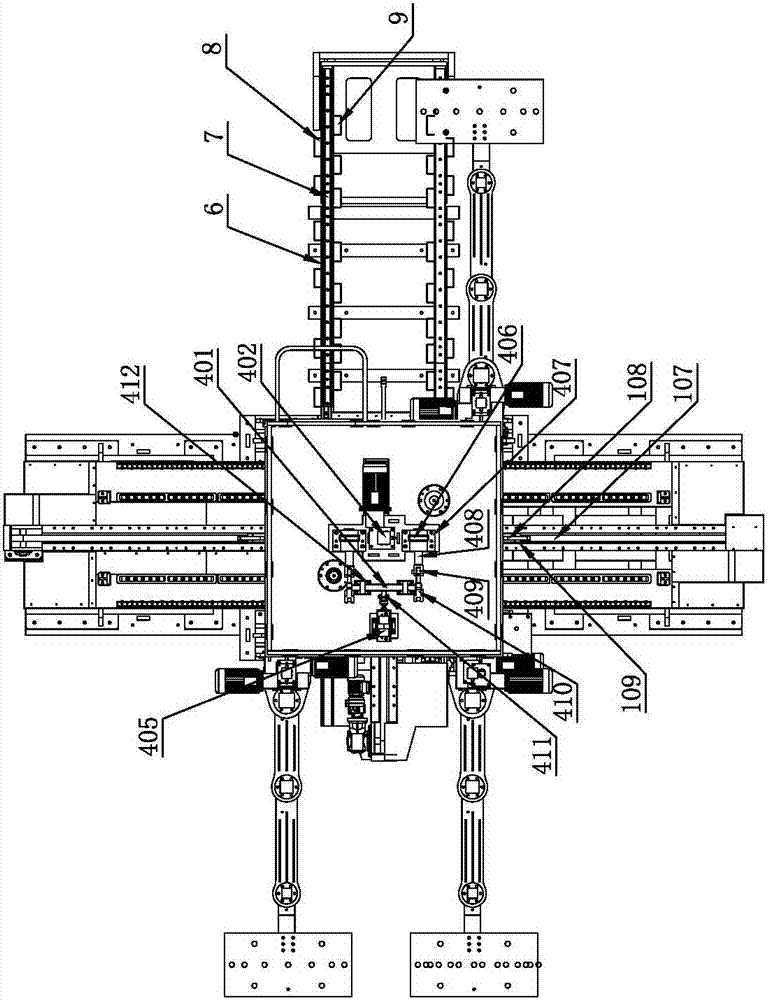

[0030] like Figure 1 ~ Figure 1 2 shows a mold changing device for a press, which includes a mold changing trolley 3 and a mold changing platform. The mold changing trolley 3 includes a frame for placing the mold frame. Rollers 303 are provided at the bottom of the frame, and a driving wheel 303 is provided inside the frame. Mechanism, the driving mechanism drives the mold changing trolley 3 to walk on the track 7 matched with the roller 303, the mold changing platform includes 4 columns 5 arranged in a rectangle, a transmission device 2 and a lifting device 4 for lifting the upper mold frame, at least 2 A vertical column 5 is connected with a transfer device 2 that can be lifted and bent automatically. The transfer device 2 can extend to the press workbench. Both ends of the mold changing trolley 3 are equipped with a mold base library 1 for placing the mold base. The fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com