Rollover prevention base of robot

An anti-rollover and robot technology, applied in the field of robotics, can solve problems such as shaking and rollover, impact on service life, unstable robot work, etc., and achieve the effect of reducing rollover and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

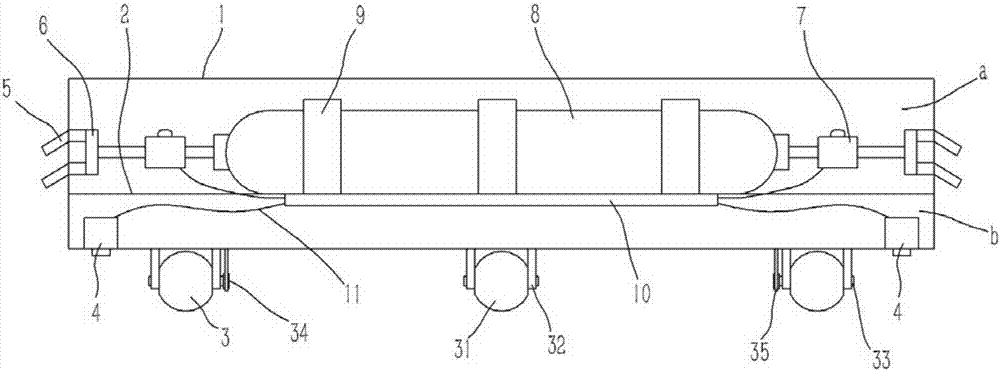

[0014] Example: see figure 1 As shown, a robot anti-rollover base includes a rectangular base 1, a partition 2 is fixed inside the base 1, the partition 2 separates the base 1 into an upper chamber a and a lower chamber b, and the bottom surface of the base 1 is fixed with A number of wheels 3, a number of distance measuring sensors 4 are fixed on both sides of the lower chamber 12 of the base 1, the probes of the distance measuring sensors 4 expose the bottom surface of the base 1, and a number of inclined wires are inserted and fixed on the two outer walls of the upper chamber a of the base 1. The jet pipe 5 is placed, the nozzle of the jet pipe 5 faces downward, and the jet pipe 5 is fixedly connected to the gas collecting pipe 6, and the gas collecting pipe 6 is connected to the nitrogen gas storage tank 8 through a pipeline, and the connection between the gas collecting pipe 6 and the nitrogen gas storage tank 8 An electromagnetic valve 7 is fixedly connected to the pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com