Processing method for valve assembly

A technology of valve components and processing methods, applied in the field of T-shaped valve stems, can solve the problems of no identical or similar technical solutions, quality not meeting the requirements, loose organization, etc., achieve less cutting, improve product production efficiency, and step simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

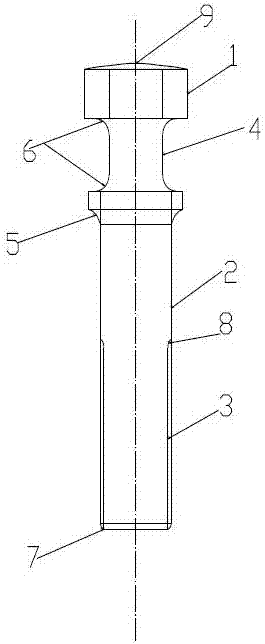

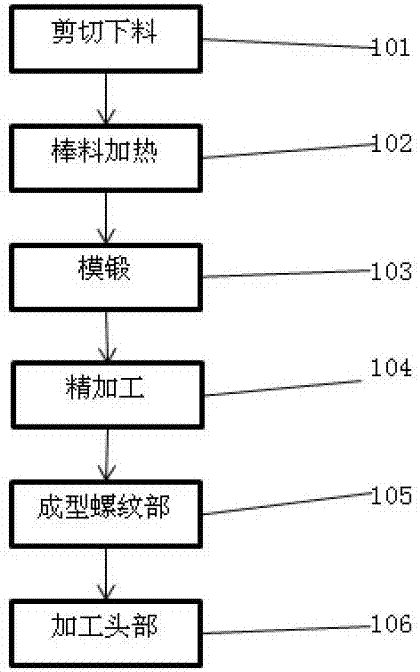

[0025] Such as figure 1 As shown, the valve assembly of the present invention is a valve stem, specifically a T-shaped valve stem. The groove 4, the connection between the head 1 and the polished rod part 2 is an arc-shaped sealing surface 5; the upper and lower ends of the trapezoidal groove 4 have circular arc chamfers 6, and the end of the threaded part 3 has circular arc chamfers 7, and the polished rod part 2 has an arc chamfer 8 at the joint with the threaded part 3; the upper end surface of the head 1 is an arc-shaped convex surface 9.

[0026] In this embodiment, the T-shaped valve stem, the upper and lower ends of the trapezoidal groove and the end of the threaded part all have arc chamfers, and the sealing surface is arc-shaped. The original right-angle chamfers are set as arc chamfers, which is convenient Die forging is basically one-time forming, which reduces the processing steps, and the stress of the arc chamfering is more uniform, which improves the service li...

Embodiment 2

[0040] In this embodiment, on the basis of Embodiment 1, the round bar stock in step (1) adopts bearing round steel;

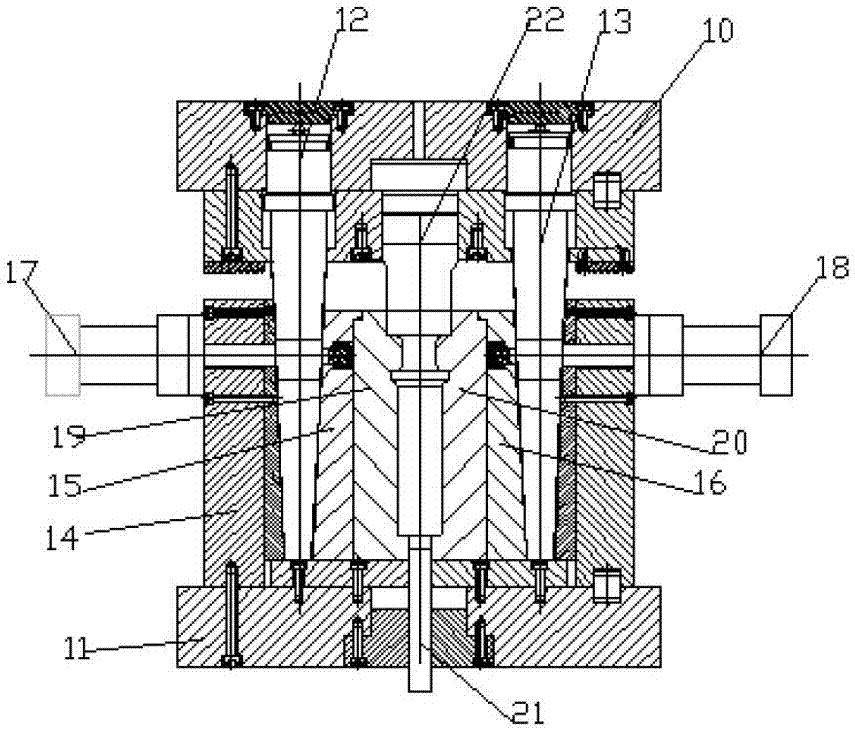

[0041] The ends of the piston rods of the left and right female mold locking cylinders in the special forging die are tapered or wedge-shaped, and the outer surfaces of the left and right female molds are provided with tapered or wedge-shaped holes that match the piston rods of the left and right female mold locking cylinders. wedge-shaped structure.

[0042] In this embodiment, the bearing round steel is used as the round bar, which has high hardness, and the hardness of the formed T-shaped valve stem reaches HRC186-230; in the special forging mold, the piston rod ends of the left and right female mold locking cylinders The upper part is a tapered or wedge-shaped structure, which improves the locking structure of the forging die, thus ensuring the smooth forging of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com