Efficient crushing device with double-speed rebound plate

A double-speed rebound plate and crushing device technology, which is applied in grain processing and other directions, can solve the problems of device damage, poor rebound effect, and low crushing efficiency, and achieve the effects of sufficient crushing treatment, increased contact range, and improved crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

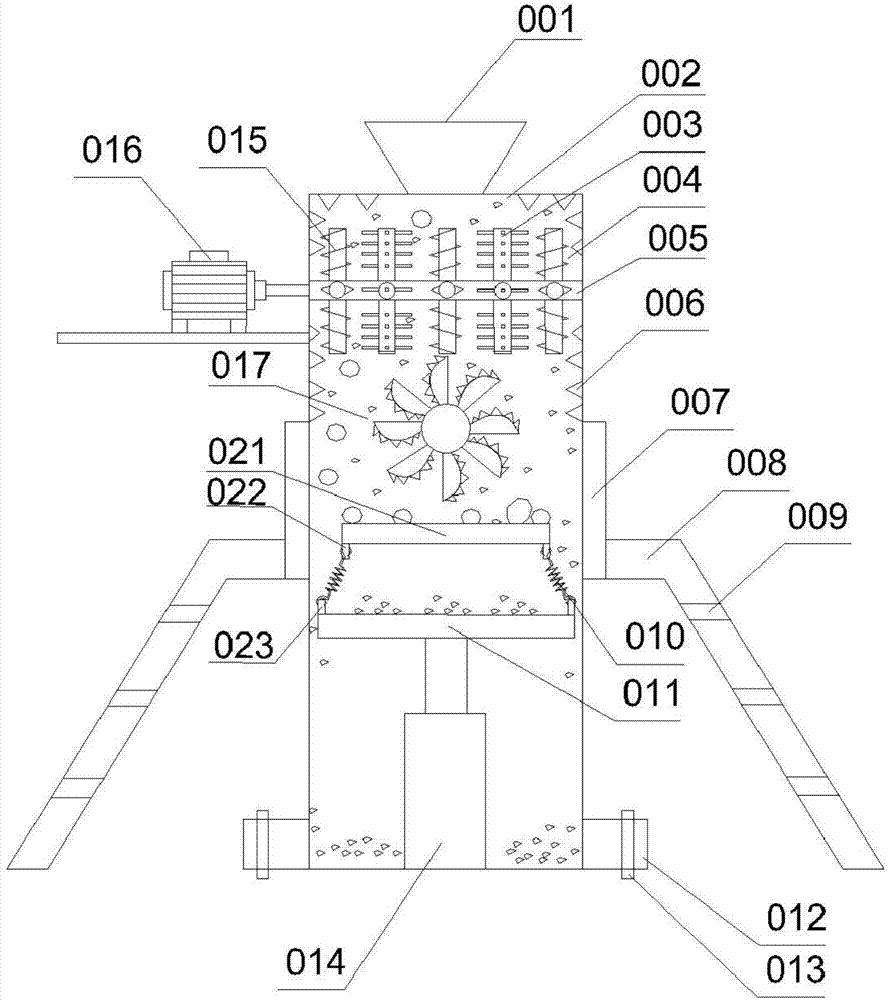

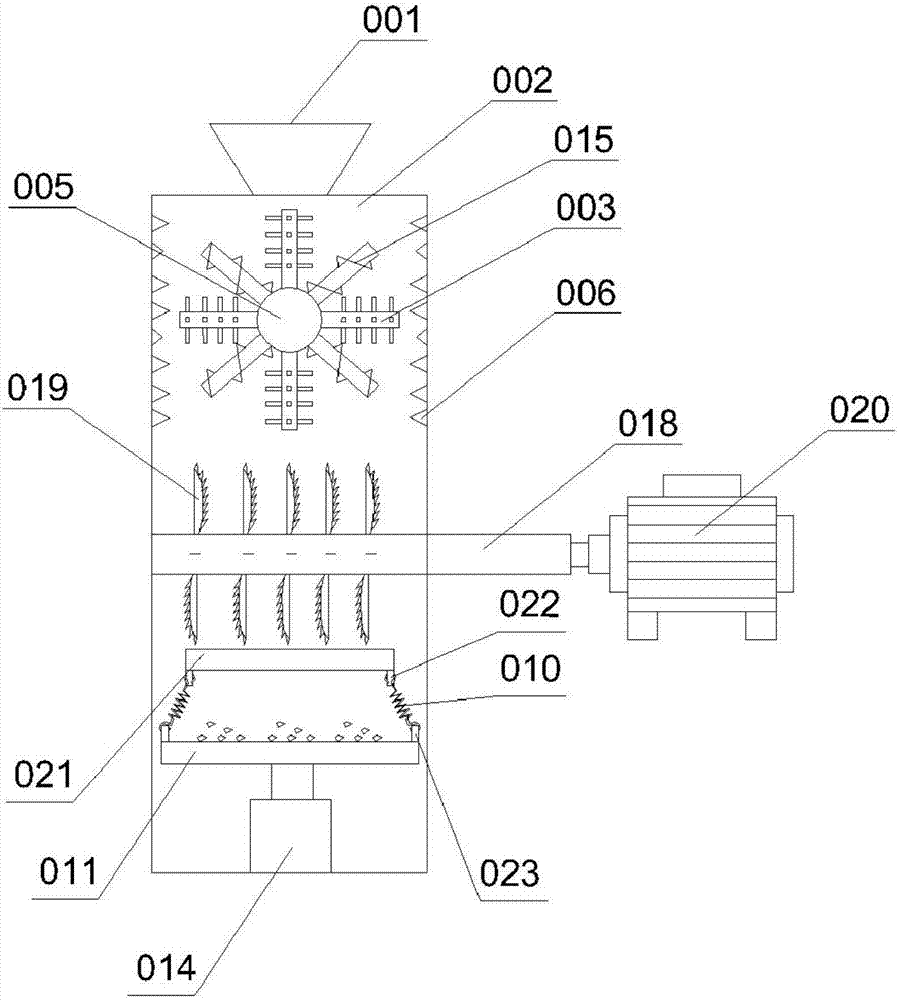

[0025] Such as figure 1 As shown, this embodiment provides a high-efficiency crushing device with a double-speed rebound plate, including a crushing device housing 002, and the top and bottom of the crushing device housing 002 are respectively provided with a feed port 001 and a discharge port 012. The valve 013 is set, the primary crushing mechanism 004 and the secondary crushing mechanism 017 are arranged in sequence from top to bottom in the crushing device housing 002, and the bottom of the crushing device casing 002 is connected with the square elastic plate 021 and the square support in sequence from top to bottom. The steel plate 011 and the telescopic cylinder 014 that drives the square supporting steel plate 011 to reciprocate up and down, the bottom of the telescopic cylinder 014 is fixed in the bottom of the crushing device housing 002, and the four corners of the square elastic plate 021 are all provided with pull buttons 022, The four corners of the square support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com