Current sensor test device and test method

A technology of current sensor and test device, applied in measurement devices, instruments, measurement of electrical variables, etc., can solve the problems of poor current source stability, limited accuracy and stability, and infeasible, to improve measurement accuracy, Ease of measurement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

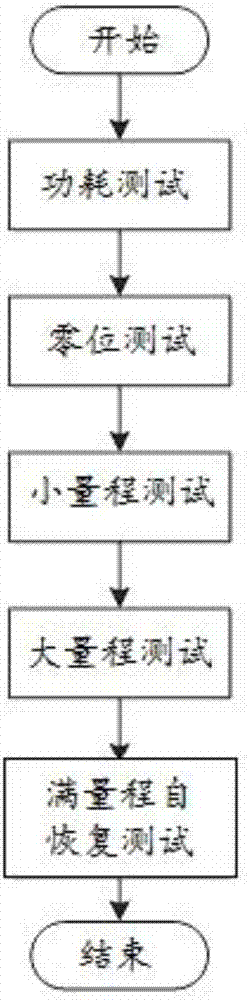

[0025] see figure 1 The current sensor testing device comprises a current source 1, a power supply one 2, a power supply two 3, a standard current sensor 4 and an ammeter 5, and the current source is used to provide the primary side bus current to the standard current sensor and the current sensor 6 to be measured, and the current A current bus 11 is connected between the two output ends of the source, and the current bus is used to pass through the magnetic core A61 of the current sensor to be measured and the magnetic core B41 of the standard current sensor in sequence (including that the current bus first passes through or winds the magnetic core A, the case of passing through or winding the magnetic core B and the current bus first passing through or w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com