A frictionless servo actuator

A servo actuator, frictionless technology, applied in the field of hydraulic servo cylinder, can solve the problems of the control effect of piston rod and seal servo system, and achieve the effect of easy hydraulic servo system control and elimination of nonlinear effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

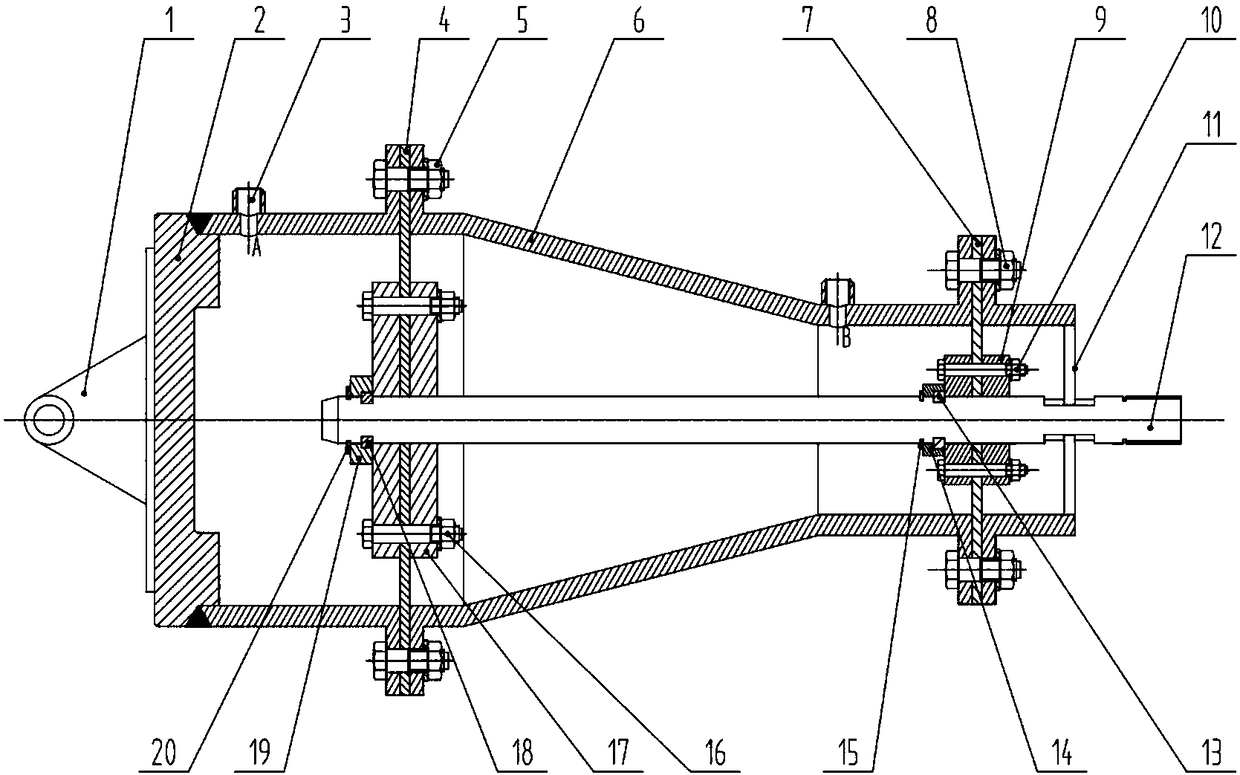

[0016] A frictionless servo actuator, the cylinder body 6 is a three-stage structure of left, middle and right. A rubber bladder I4 is placed between one end of the cylinder body 6 in the middle and the cylinder body on the left side. The rubber bladder I4 and the cylinder body 4 are tightly connected by the cylinder body bolt assembly I5. The rubber bladder I4 is in close contact with the cylinder body 6 to play an external The role of sealing. A rubber bladder II7 is placed between the other end of the cylinder body 6 in the middle part and the cylinder body on the right side, and the rubber bladder II7 and the cylinder body 6 are tightly connected by the cylinder body bolt assembly II8, and the rubber bladder II7 is in close contact with the cylinder body 6 to play The role of the outer seal. The earring 1 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com