Roll stabilization gyroscope used for multimachine parallel operation mechanical flexible transmission ship

A flexible transmission and mechanical technology, applied in the direction of directly using the gyroscope to reduce the movement of the ship, to achieve the effect of increasing the heat dissipation area and space, reasonable and convenient distribution, and high anti-rolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

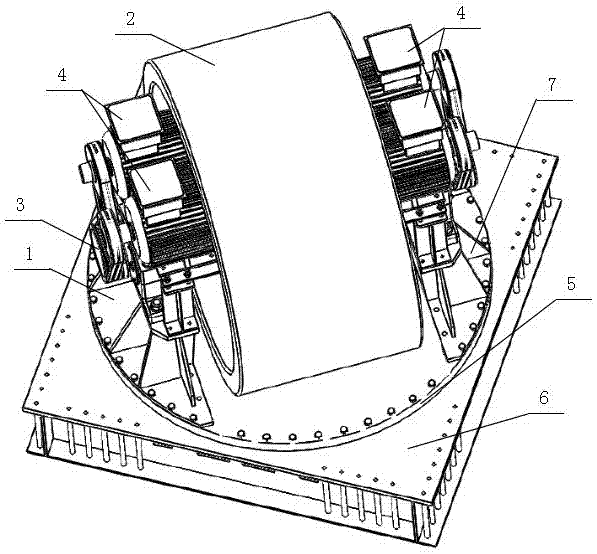

[0008] figure 1 Among them, the multi-machine parallel vehicle mechanical flexible transmission marine anti-roll gyro, including rotor 2, frame 1, base 6, etc., the rotor 2 is installed on the frame 1, the frame is installed on the base 6, the rotor shaft 3 and the surface of the base 6 Parallel, the axis of the frame 1 is perpendicular to the surface of the base 6, the frame 1 and the base 6 form a rotating pair, a turntable bearing 5 is installed between the frame 1 and the base 6, and a plurality of dampers are installed between the frame 1 and the base 6 One end of the oil cylinder 7 and the damping oil cylinder 7 is rotatably mounted on the frame 1 . A plurality of motors 4 are installed on the frame 1, and they are evenly distributed and installed on the frame 1. The output shaft of each motor 4 and the rotor shaft 3 are connected together by a V-belt drive, so that each small motor 4 can be It is conveniently and reasonably distributed in the ideal dynamic space, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com