An FET type gas sensor having a composite insulating structure and a preparing method thereof

A gas sensor and composite insulation technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., to achieve the effect of improving gas sensitivity characteristics, increasing sensitivity, and reducing the difficulty of device construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

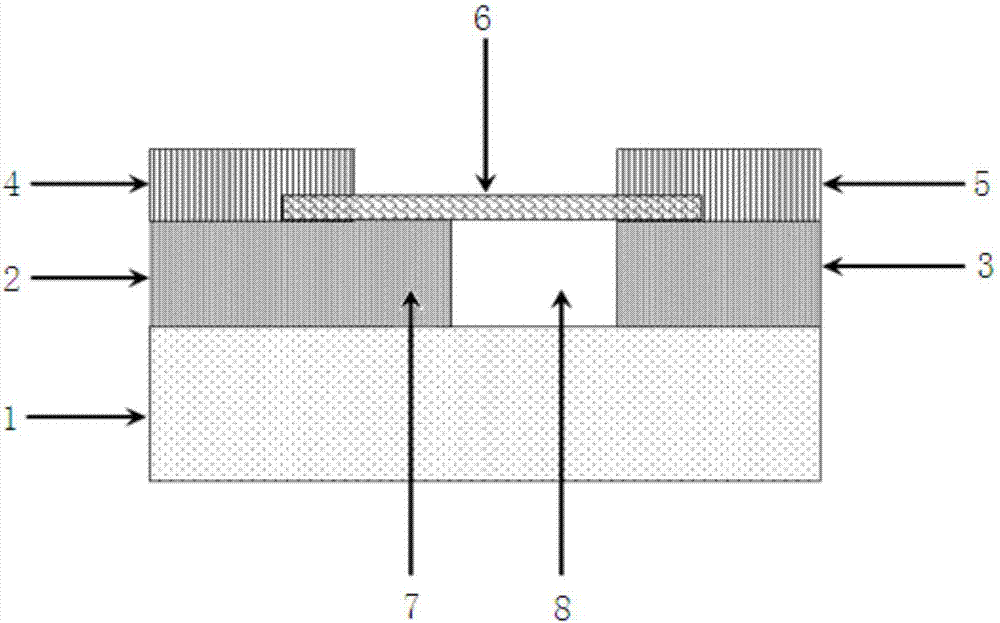

[0022] like figure 1 As shown, the FET type gas sensor with a composite insulating structure provided by the present invention includes a gate electrode 1, a first supporting layer 2, a second supporting layer 3, a source region 4, a drain region 5 and a micro-nano single crystal semiconductor 6 , wherein the width of the first support layer 2 is greater than the width of the source region 4 .

[0023] The first support layer 2 and the second support layer 3 are respectively fixed on both sides of the top of the gate electrode 1, the top of the first support layer 2 is glued and fixed to the source region 4, the first support layer 2 is not flush with the inner end of the source region 4, And the part inside the first support layer 2 that is longer than the source region 4 is a solid insulating layer 7 , and a first groove is opened inside the bottom of the source region 4 . The top of the second supporting layer 3 is glued and fixed to the drain region 5 , the second support...

Embodiment 2

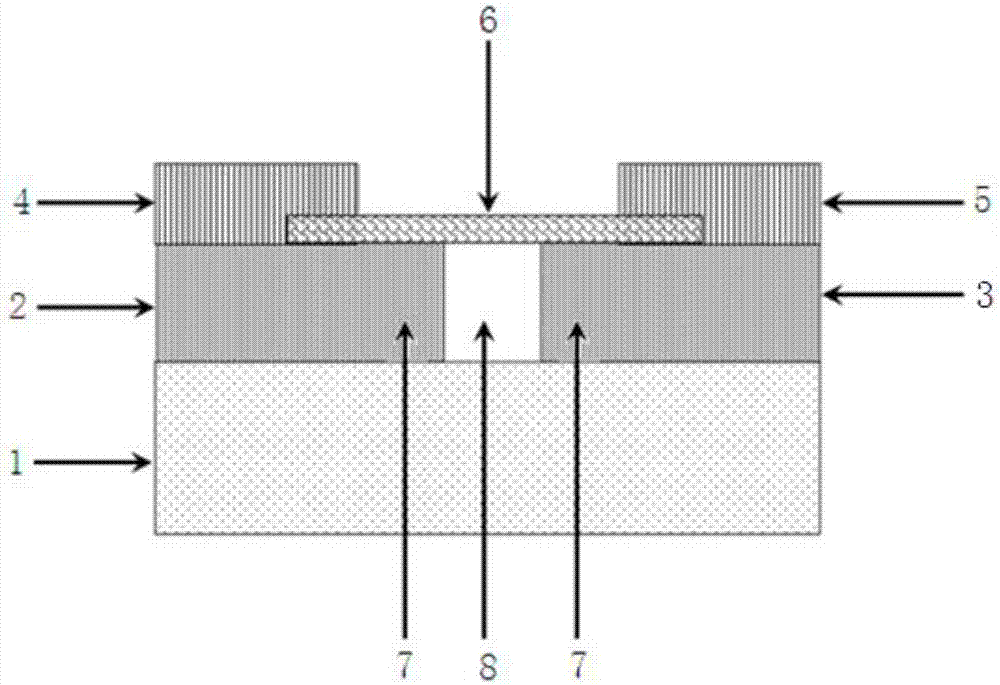

[0025] like figure 2 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the width of the second support layer 3 in this embodiment is greater than the width of the drain region 5, and the second support layer 3 and the inner end of the drain region 5 The part inside the first support layer 2 that is longer than the source region 4 and the part inside the second support layer 3 that is longer than the drain region 5 are all solid insulating layers 7. The top of the gate electrode 1, the first support layer 2 and the second The gap between the supporting layers 3 and the cavity formed at the bottom of the micro-nano single crystal semiconductor 6 constitute an air-gap insulating layer 8 .

[0026] In the above embodiments, the gate electrode 1 can be a conductive substrate or an insulating substrate with a conductive material on top.

[0027] In each of the above-mentioned embodiments, the micro-nano single crystal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com