Rotary Vibration Test Rig for Traveling Wave Vibration Testing of Composite Cylindrical Shells

A vibration test bench and vibration testing technology, which is applied in vibration testing, machine/structural component testing, measuring devices, etc., can solve problems such as failure to meet testing requirements, and achieve the goal of avoiding damage, reducing test errors, and stabilizing and effective clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

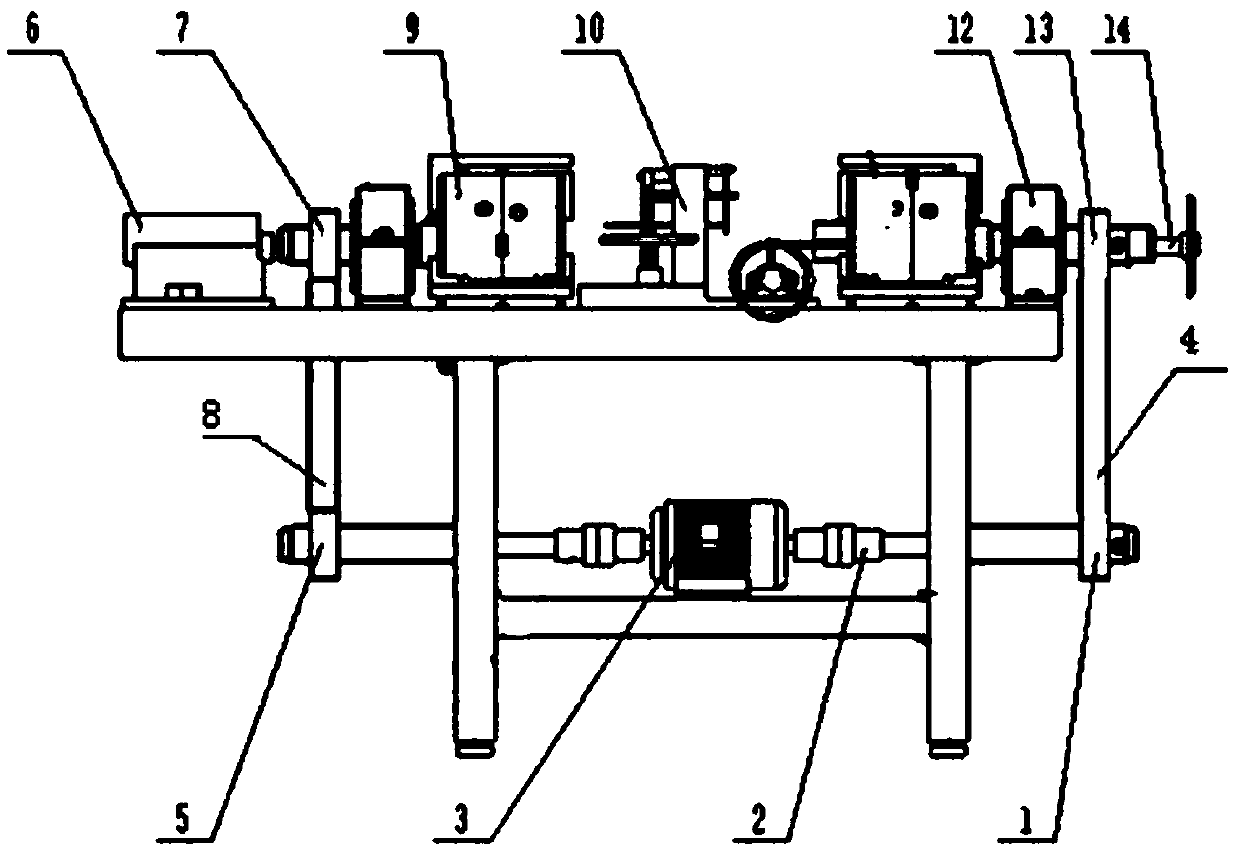

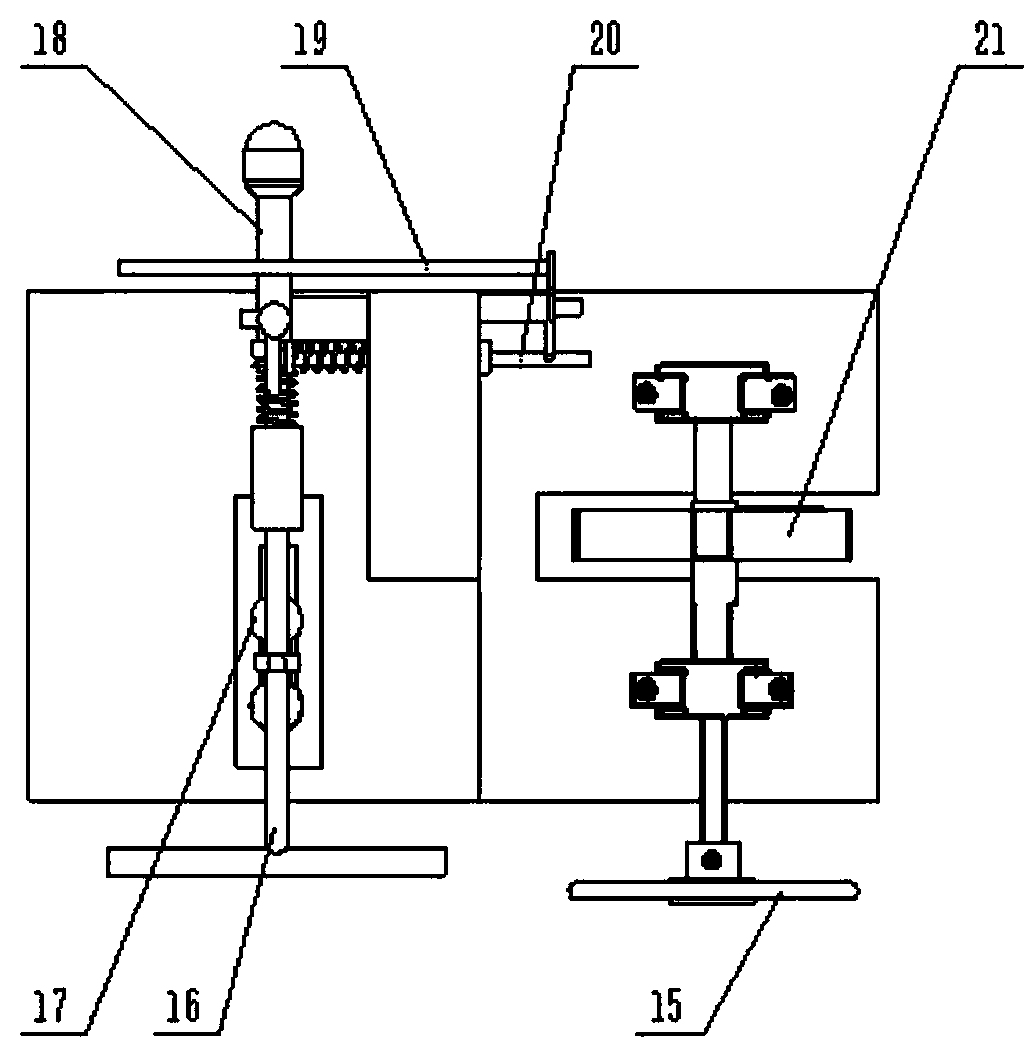

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings. figure 1 It is the front view of the rotary vibration test bench of the present invention; figure 2 It is a top view of the ejection excitation device of the rotary vibration test bench of the present invention; image 3 It is a top view of the laser circular scanning device of the rotary vibration test bench of the present invention; Figure 4 It is an axonometric view of the elastic excitation device of the present invention; Figure 5 It is the axonometric view of the rotational vibration test bench after the composite cylindrical shell is fixed in the present invention; Figure 6 It is a schematic diagram of the tie rod fixing device of the ejection excitation device of the present invention.

[0036] As shown in the figure, the rotary vibration test bench for the traveling wave vibration test of the composite cylindrical shell includes a remote transmission de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com