A cup holder clamping mechanism

A clamping mechanism and a cup holder technology, applied in the field of auto parts, can solve the problems affecting the space utilization rate of automobile armrests and occupy a large space, and achieve the effects of stable and effective occupied volume, convenient and reliable use, and simple structure of the cup holder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

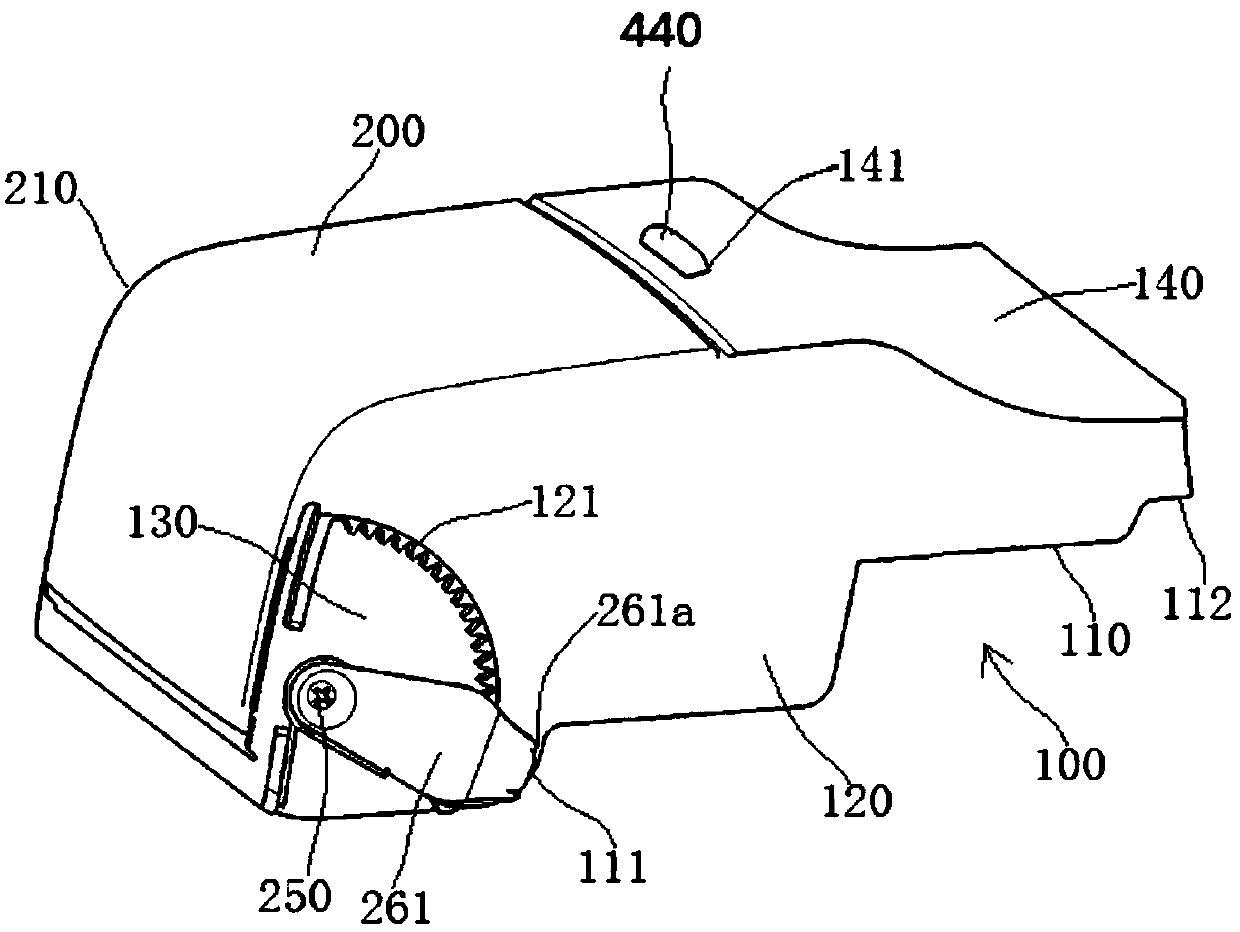

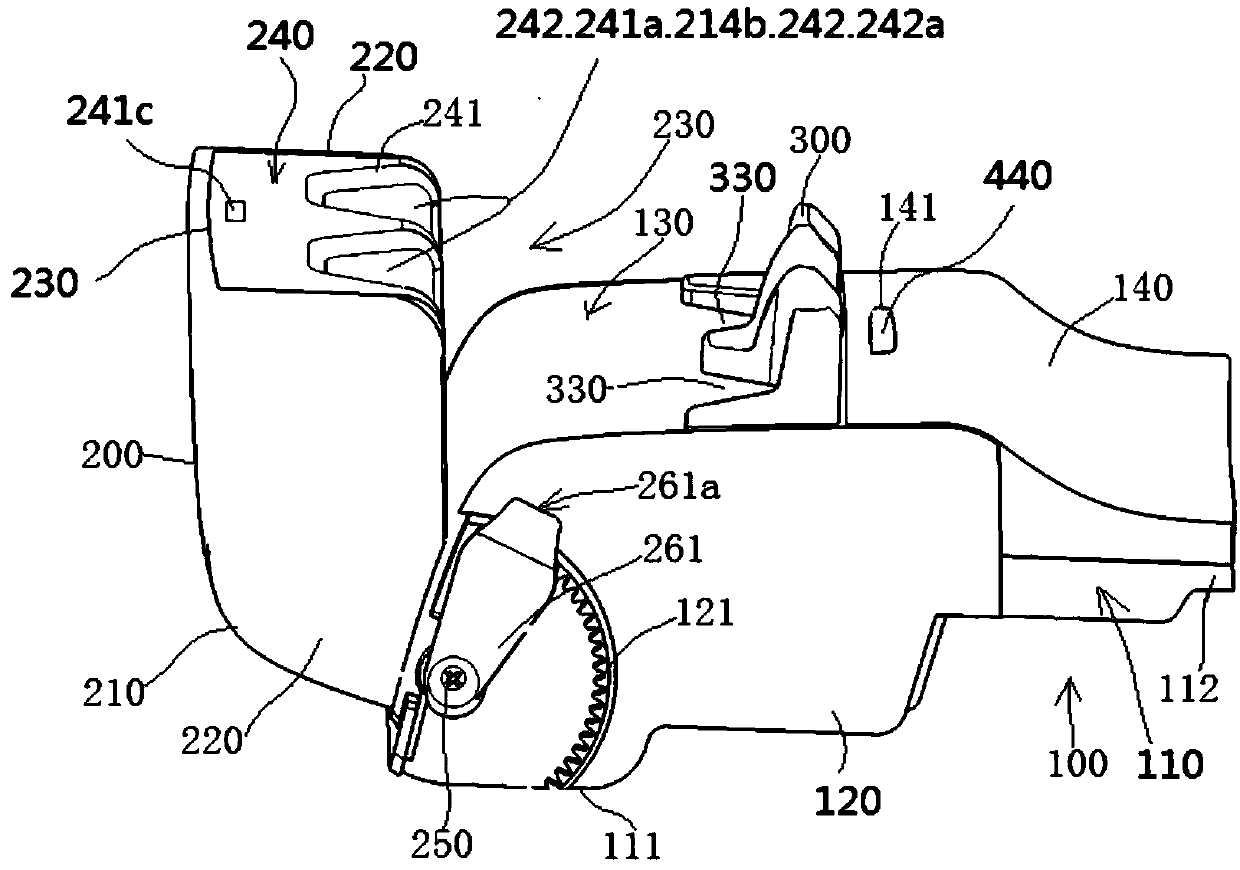

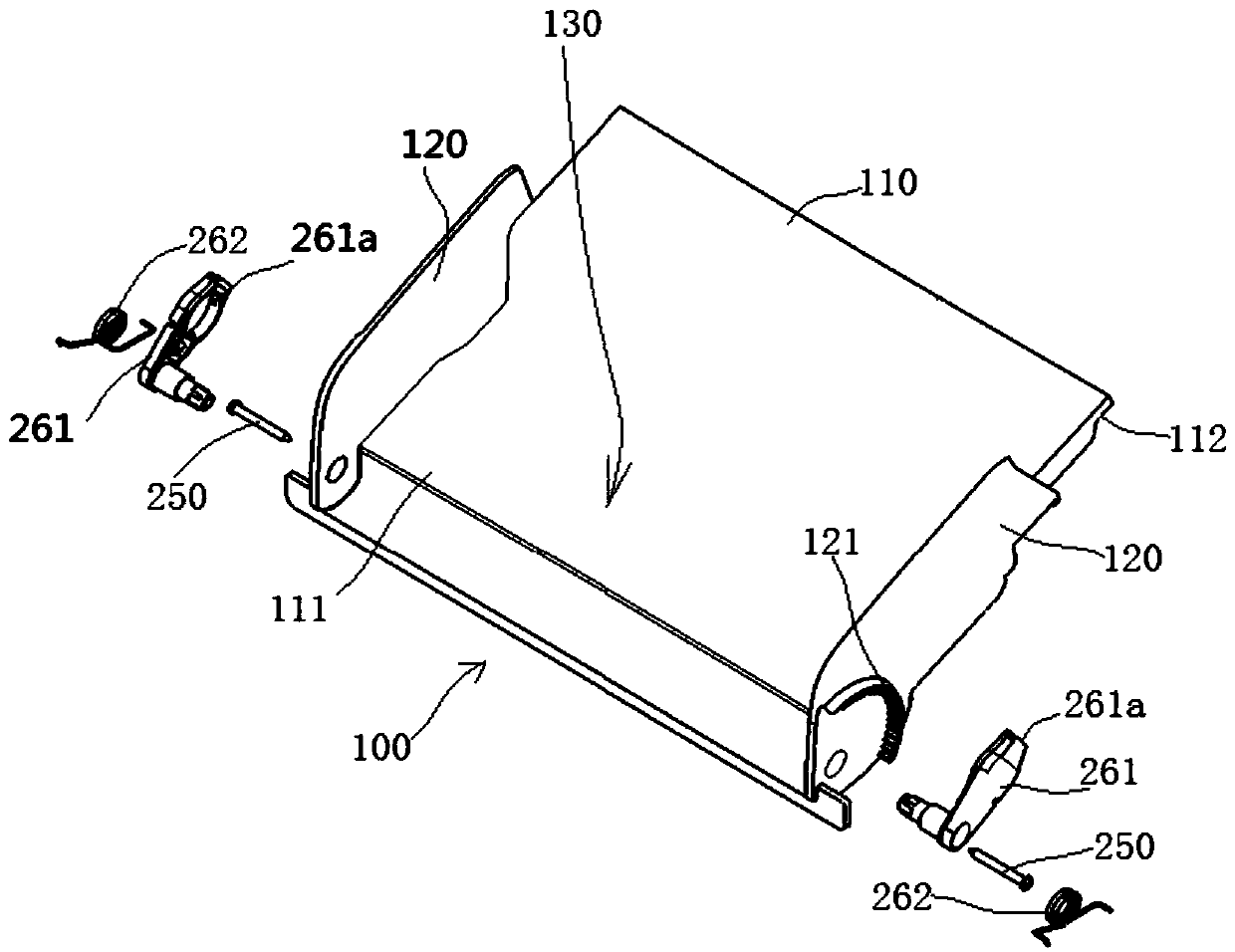

[0038] See attached Figure 1 to Figure 4 , a cup holder clamping mechanism given in the figure includes a cup holder body 100, the cup holder body 100 is composed of a cup holder body lower cover 110 and two sides of the cup holder body lower cover 110 connected as a whole The side plate 120 is formed, the lower cover plate 110 of the cup holder body is stepped, the front half 111 is lower than the rear half 112 , and the front half 111 and the two side plates 120 front half enclose a cup holder chamber 130 .

[0039] see in conjunction Figure 9 , the cup holder clamping mechanism also includes a cup holder accommodating chamber cover 200, the cup holder accommodating chamber cover 200 has an arc-shaped cover wall 210 at the lower part and two side pieces connected with the two sides of the cover wall 210 as a whole The wall 220 , the cover wall 210 and the two side walls 220 enclose a cup holder front clamping part installation cavity 230 , and a cup holder front clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com