A sample clamping device for laser drilling

A technology of laser drilling and sample clamping, applied in auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., can solve the problems of reducing material utilization rate and processing efficiency, so as to improve material utilization rate and processing efficiency, and reduce clamping The effect of holding the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

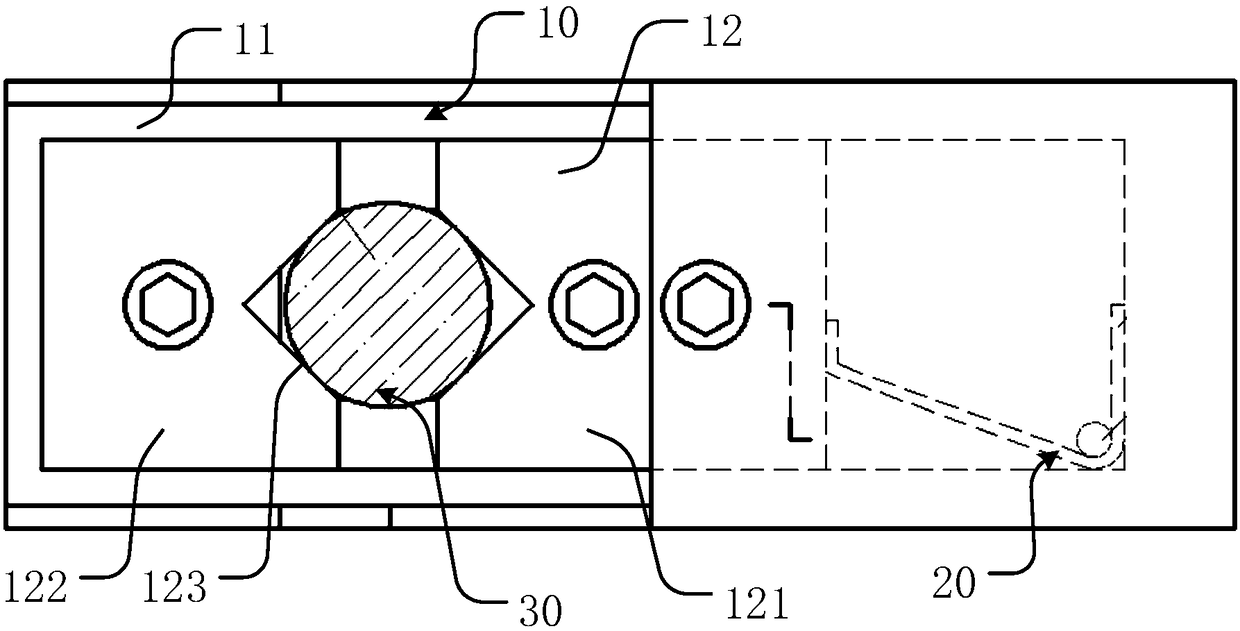

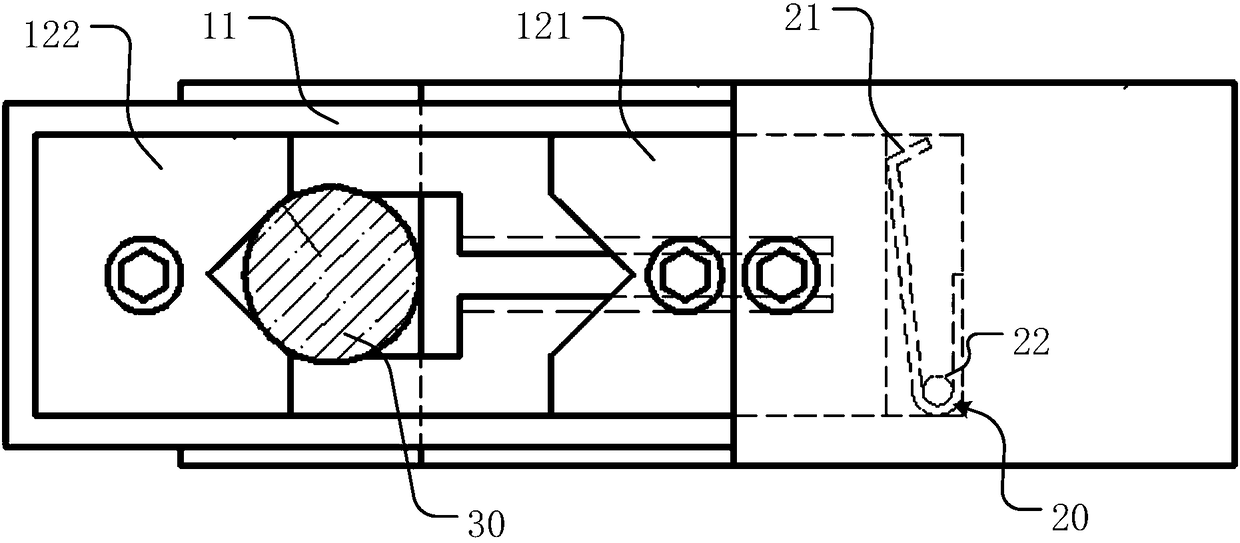

[0026] Such as figure 1 , 2 As shown, the sample clamping device for laser drilling according to one embodiment of the present invention generally includes a clamping seat 10 for clamping a sample 30, and an elastic device that provides clamping power for the clamping seat 10 20.

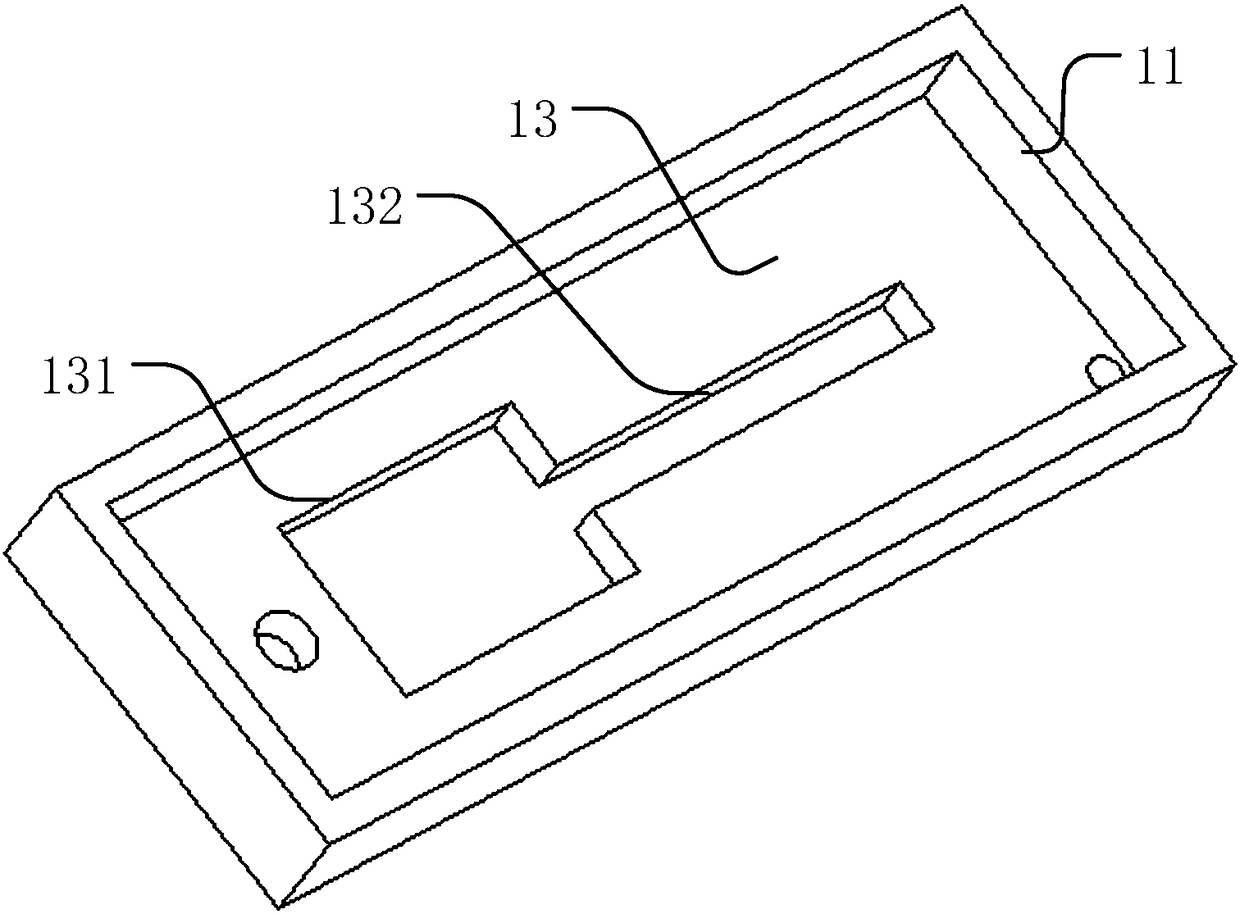

[0027] The clamping seat 10 may include a housing frame 11 with a hollow structure for placing the sample, and a clamping plate 12 installed in the housing frame 11 for movably clamping the sample 30 . The elastic device 20 is installed in the receiving frame 11 to exert a clamping force on the clamping plate 12 to clamp the sample 30 .

[0028] The sample 30 involved in the present embodiment may be a component with a circular cross section, which is placed in the clamping seat 10 and clamped horizontally by the clamping plate 12 from the side of the circle, and the elastic device 20 can make the clamping The plate 12 maintains the state where the sample 30 is sandwiched. After the sample 30 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com