Large spherical screen mounting system and construction method thereof

A spherical screen and system technology, applied in the direction of arched structure, building structure support, building structure support, etc., can solve the problems of difficult installation of large spherical screens, large amount of disassembly of the installation frame, and influence on the installation of metal screens, etc. Safe construction, reduce the cost of building and dismantling, and enhance the effect of illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

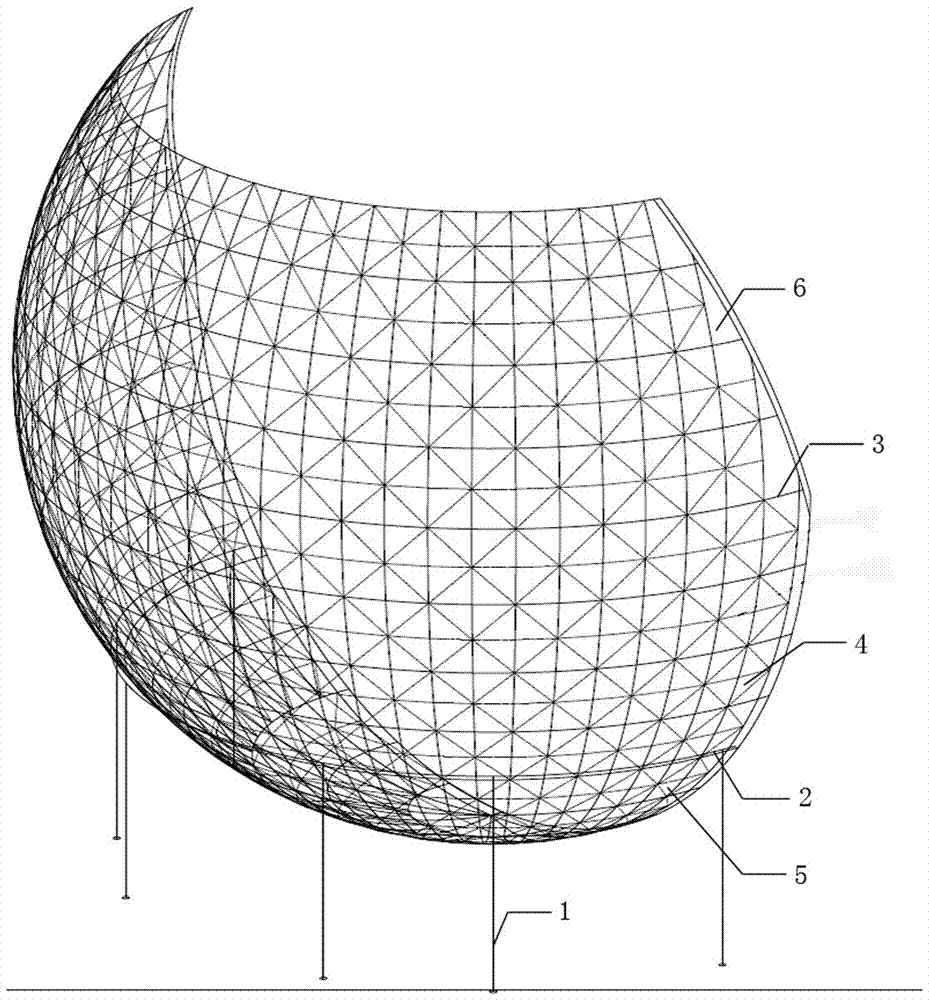

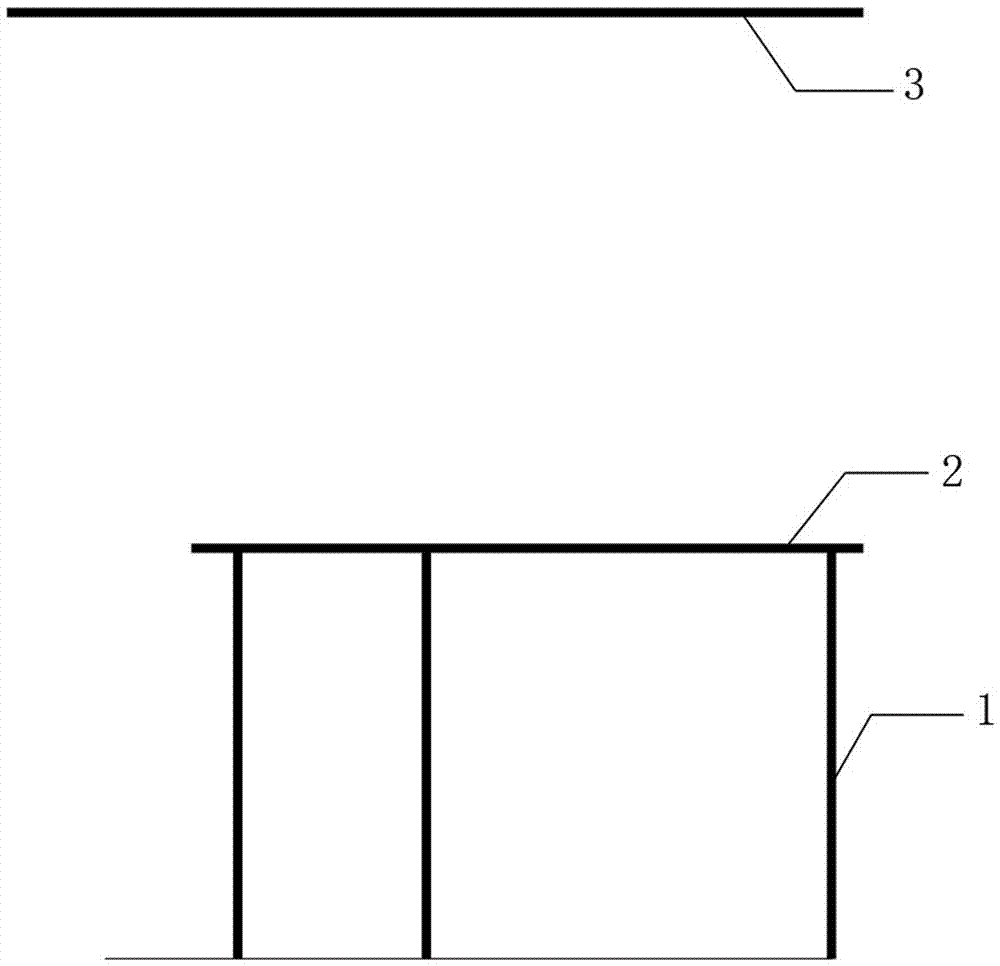

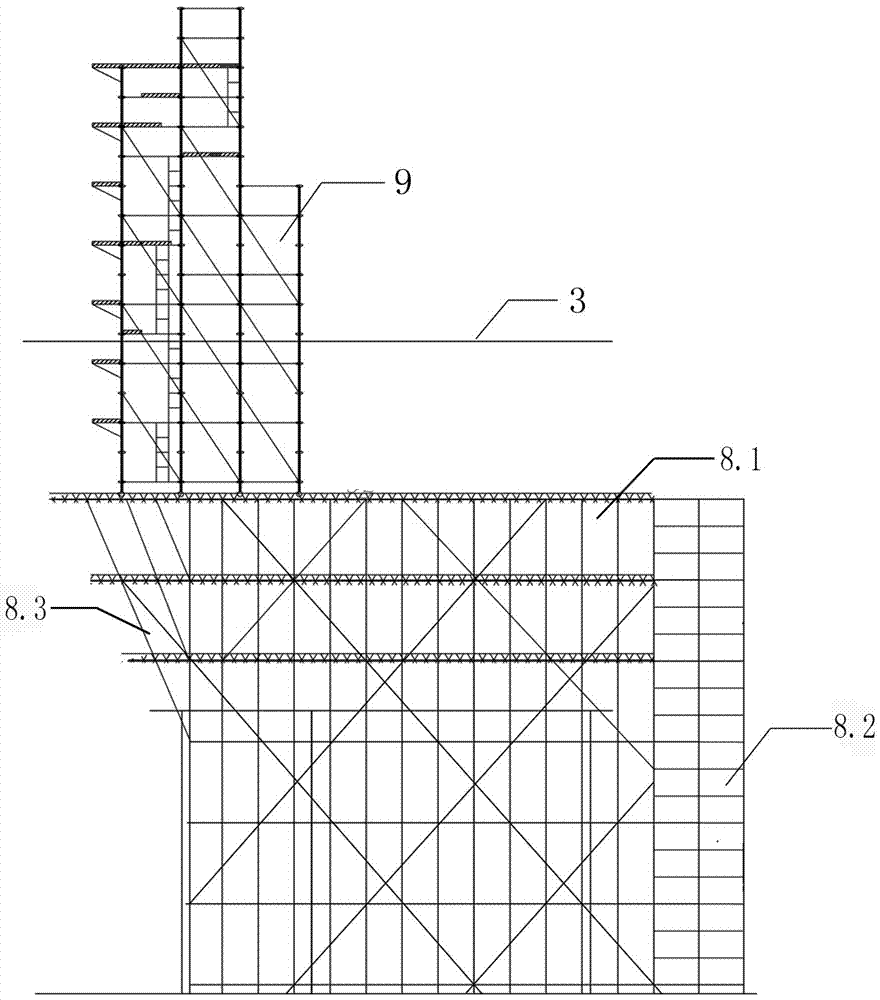

[0051] Examples see figure 1As shown, a large-scale spherical screen installation system and its construction method, the height of the spherical screen of this project is about 22m, the installation method can be used for the installation of large-scale 4D cinema spherical screen steel structure grid frame and metal screen, including spherical screens and spherical screens The inner construction platform; the spherical screen includes support columns 1 arranged on the ground at intervals in an arc shape, lower chord arc beams 2 horizontally connected to the top surface of the support columns, and equatorial arc beams arranged directly above the lower chord arc beams. Beam 3, the spherical steel structure grid connected to the lower chord arc beam and the equatorial arc beam and the metal screen connected to the inner spherical surface of the spherical steel structure grid; the spherical steel structure grid includes an upper grid, a middle grid Frame 4 and lower network frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com