Small-diameter double-sided jacquard fabric and its 3D jacquard knitting method on small circular knitting machine

A technology of double-sided jacquard and small circular knitting machines, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve problems such as uneven cohesion pressure, easy deformation after cleaning, and inability to connect patterns on the outer surface into a whole, so as to achieve clear The effect of high density and high coil density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

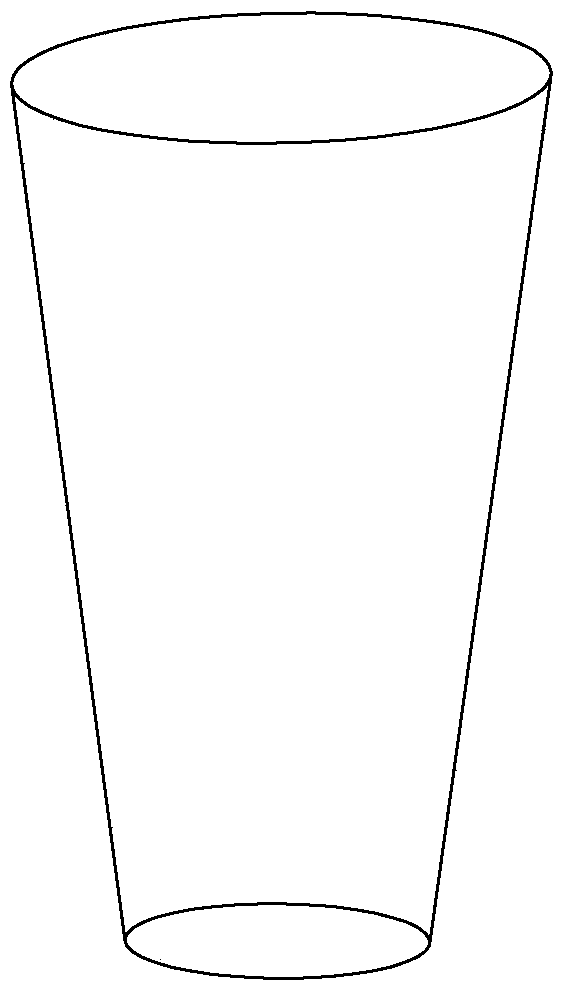

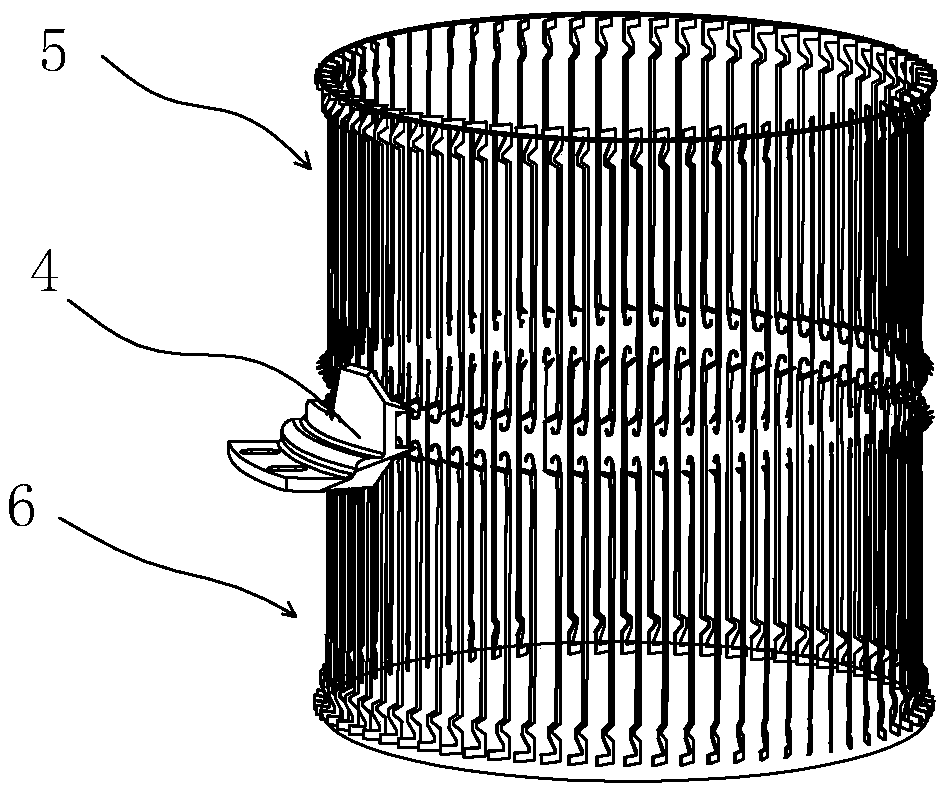

[0030] Such as figure 2 As shown, a small-diameter double-sided jacquard fabric includes a seamless tubular shape blank, and the seamless tubular shape blank has a caliber of 8cm to 15cm. and the outer layer, the shape of the seamless tubular blank is changed by changing the number of courses, figure 2 The tandem coils gradually decrease from the upper middle end to the lower end.

[0031] The front and back sides of the seamless tubular shape blank are provided with the same pattern, different colors or the same pattern, the front and back sides of the seamless tubular shape blank have no heads, and each row of the seamless tubular shape blank has the same pattern as the lower needle. Count the same number of pattern-forming coils.

[0032] A method of 3D jacquard knitting on a small circular machine for preparing small-diameter double-sided jacquard fabrics, the method comprising the following steps:

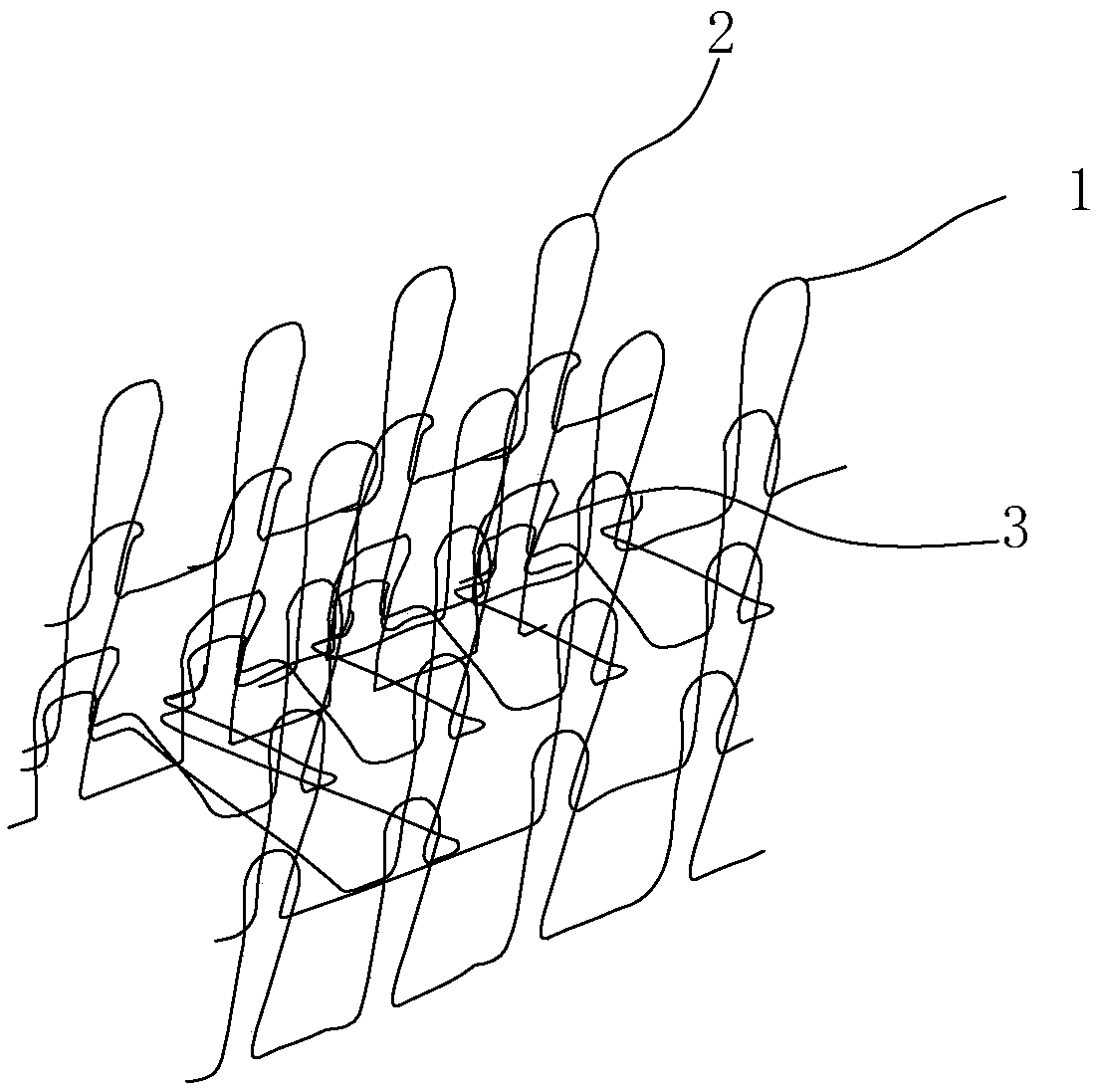

[0033] Such as figure 1 As shown, upper knitting needle 5 of A rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com