Signature cutting composite mechanism for autoclaved aerated board

A technology of autoclaving, gas filling and plate materials, which is applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of large site space and achieve good systematic results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

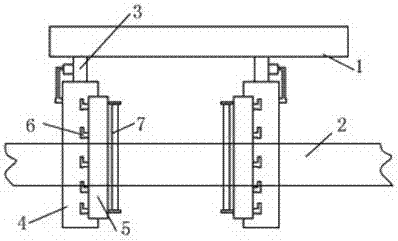

[0010] Combine below figure 1 Specific description embodiment:

[0011] The composite mechanism for stamping and trimming of autoclaved and aerated plates includes a bracket 1 and a track 2, the bracket 1 is arranged directly above the track 2, and knives are arranged on both sides of the track 2 on the bracket 1 Column 3, the outer sleeve of knife post 3 is set on the rotating sleeve 4, and the rotating sleeve 4 is provided with the arm groove tool holder 5, and one side of the arm groove tool holder 5 is provided with the cutter 6, and the knives on the rotating sleeve are arranged alternately, and the rotating sleeve It rotates under the drive of the cylinder, so that the cutter on the trough tool rest is close to the plate for trimming; the other side of the trough knife rest 5 is provided with a stamp tube 7, and the rotary sleeve 4 is driven by the cylinder to make the stamp tube 7 Close to the plate on the track, when the printing tube is close to the surface of the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com