Sand shakeout device for agricultural mechanical castings

A technology of shakeout device and agricultural machinery, applied in the field of agricultural machinery, can solve problems such as unfavorable work efficiency, time-consuming and labor-intensive, etc., and achieve the effect of good promotion and utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiment of the utility model is described below in conjunction with accompanying drawing, and embodiment does not constitute restriction of the utility model:

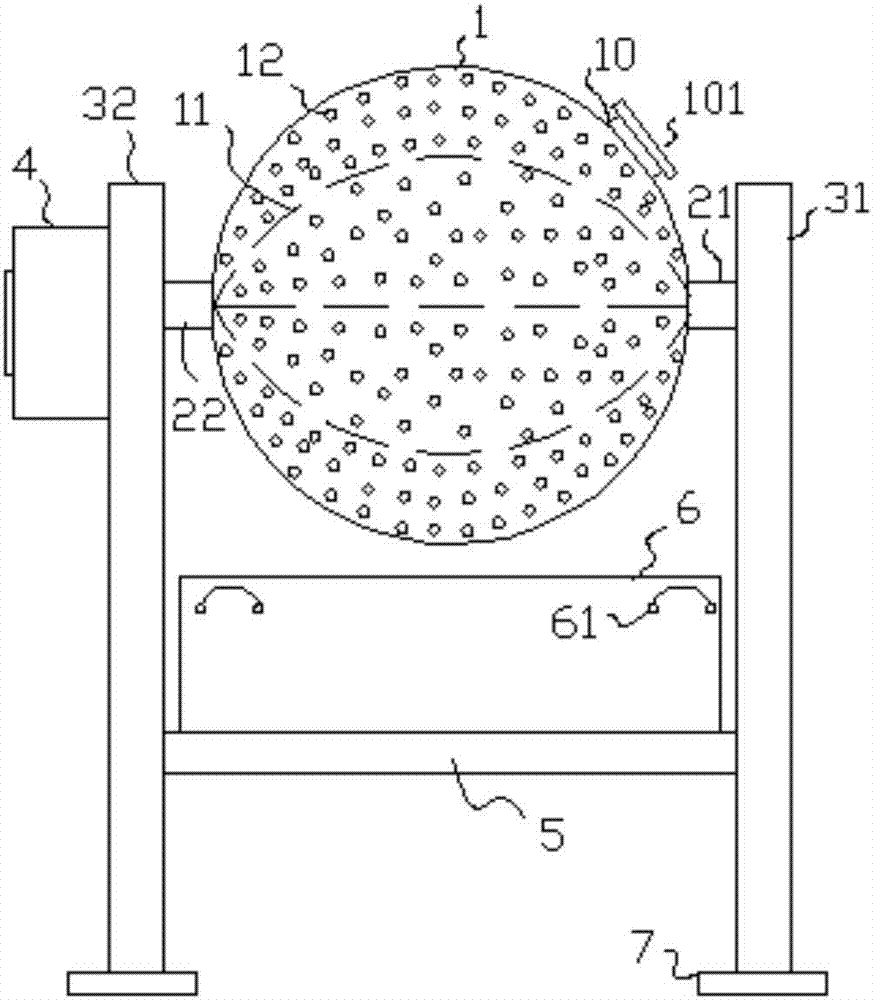

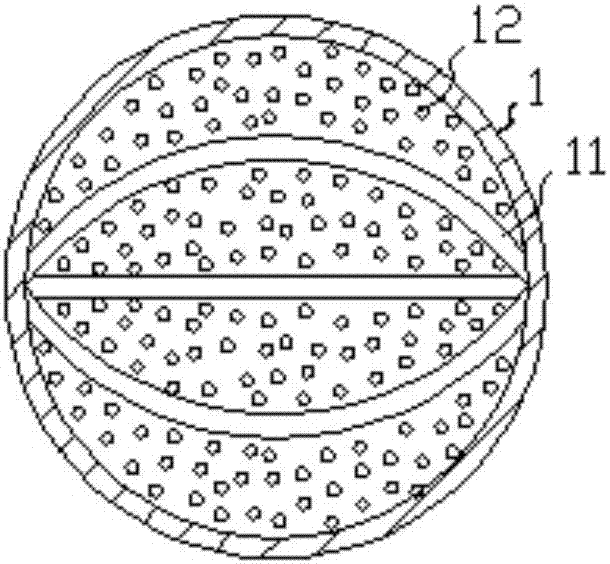

[0025] Such as figure 1 , figure 2 (Casting entrances and exits are not shown), the structure of this kind of agricultural machinery castings shakeout device includes a spherical work chamber 1, the side wall of the work chamber 1 is provided with casting entrances and exits 10, and there are 10 casting entrances and exits. A cover 101 is provided. When in use, castings can be put into the working chamber from the casting inlet and outlet, and then the cover is covered to prepare for the subsequent casting rotation and knocking.

[0026] In the above embodiment, specifically, the inner surface of the working chamber 1 is provided with several strip-shaped bosses 11 in the transverse direction. When in use, when the working chamber rotates, the strip-shaped boss can block the casting and at the same time p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com