Deep cycle battery lead paste preparation method with characteristic of easy 4BS generation

A deep-cycle battery and manufacturing method technology, applied in battery electrodes, lead-acid battery electrodes, circuits, etc., can solve problems such as difficulty in generating 4BS, achieve the effects of reducing energy consumption, ensuring battery life, and improving battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Put 100Kg of lead powder into the vacuum paste machine, add 75g of fiber to the lead powder, dry stir for 3 minutes, add 11.5L of water within 1 minute, stir for another 3 minutes, then add 10.5kg of acid (the specific gravity of the acid is 1.4g / ml), adjust the angle of the acid nozzle, add 85% of the acid within 3 minutes, control the total time of acid addition within 12 minutes, and set the highest temperature to 80°C, keep the vacuum and stir for another 5 minutes , and then add 1.5kg of sulfuric acid mixture (antimony trioxide and stannous sulfate to the remaining sulfuric acid to obtain, consisting of 1.3kg of dilute sulfuric acid with a density of 1.15g / ml, 100g of antimony trioxide, and 100g of stannous sulfate ) within 2 minutes into the primary mixed acid lead paste for 4 minutes of stirring reaction, and then lower the temperature to less than 45°C to obtain deep cycle battery lead paste 1.

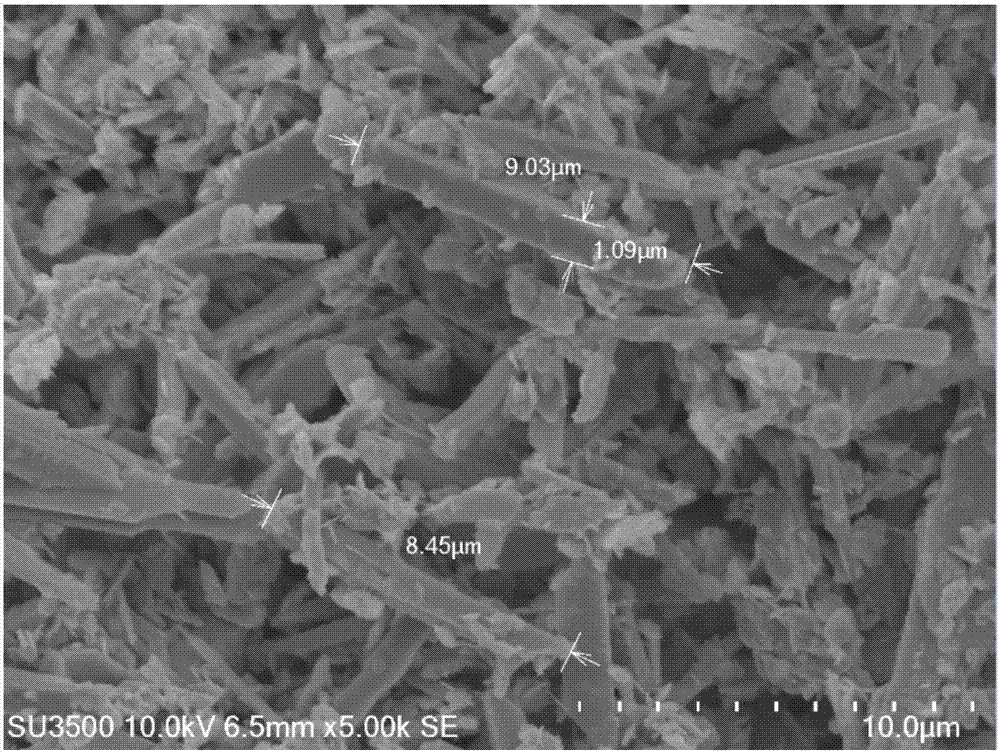

[0031] The formed product was observed under a scanning electron ...

Embodiment 2

[0035] Put 100Kg of lead powder into the vacuum paste machine, add 75g of fiber to the lead powder, dry stir for 5 minutes, add 11.7L of water within 1 minute, stir for another 5 minutes, then add 10kg of acid (the specific gravity of the acid is 1.4g / ml ), adjust the angle of the acid feed nozzle, add 85% of the acid within 5 minutes, control the total time of acid addition within 10 minutes, and set the highest temperature to 65°C, keep the vacuum and stir for another 7 minutes, Then add 1.5kg of sulfuric acid mixture (to obtain by adding antimony trioxide and stannous sulfate to the remaining sulfuric acid, composed of 1.3kg of dilute sulfuric acid with a density of 1.3g / ml, 100g of antimony trioxide, and 100g of stannous sulfate) Mix it into the primary mixed acid lead paste within 1 minute for a stirring reaction for 5 minutes, and then lower the temperature to less than 45°C to obtain deep cycle battery lead paste 2.

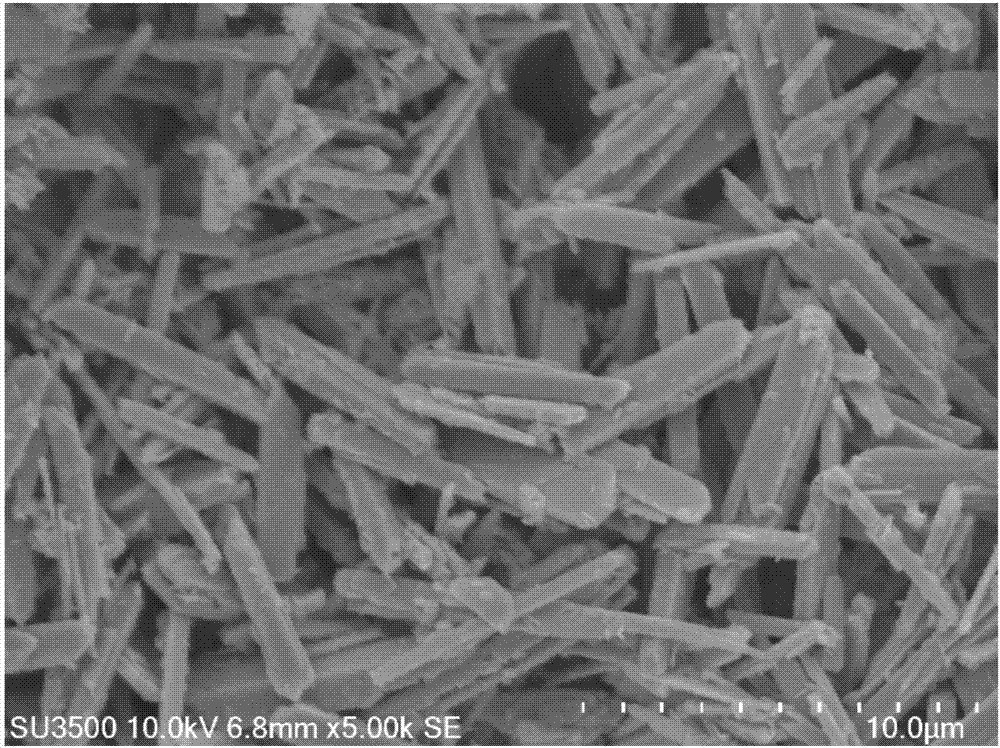

[0036] The formed product was observed under a scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com